Factory single wheel cutting knurling tool factory direct sales

-

Supplier: Taizhou Ke Chi Machinery Co., Ltd. -

Region: Zhejiang, China -

Price: $221.70 / 1 - 4 pieces

$217.60 / >=5 pieces -

Min. Order: 1 piece

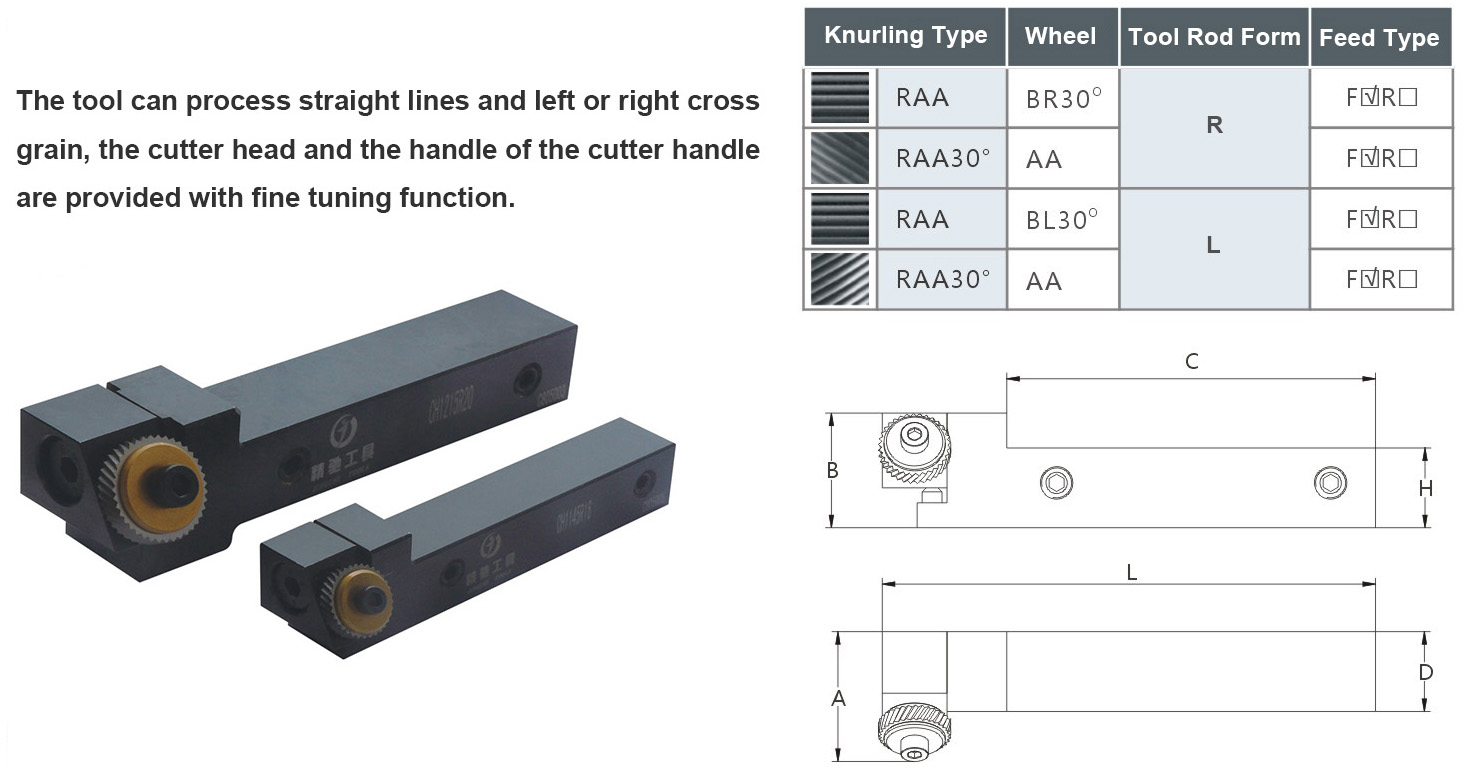

| brand: | Jingchi | process: | Straight lines and horizontal stripes |

| Finish: | Longer service life TiCN | product name: | Single Wheel Knurling Tool |

| Original Equipment Manufacturer: | accept | Supply capacity: | 500 Maker CNC Cut Knurling Tools per Month |

| usage: | Lathe, CNC | port: | Ningbo or Shanghai |

| Packaging Details: | carton | direction: | right + left |

| Processing range: | 5 - 250mm | Package: | carton |

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram | Model: | CH1215R25 |

| place of origin; place of origin: | Zhejiang, China | Certificate: | ISO9001 |

| type: | face milling, knurling | Material: | high speed steel |

Factory single wheel cutting knurling tool factory direct sales

KC-CH Cut Knurling Tool

Knurling features: The knurling tool for turning the outer diameter can adjust the cutting angle, which can protect the precision of the machine tool, and the rigidity of the small machine tool is low. Applicable models: CNC lathes, automatic lathes. Multi-spindle lathes, Swiss automatic lathes, turning and milling machines.

Applicable models: CNC lathes, automatic lathes, multi-axis lathes, Swiss automatic lathes, turning and milling machines.

Single Wheel Cut Knurling Tool

product data

Model | direction | Processing range | wheel size | Shank size | Parts | |||||

One | Second | C | D | H | large | |||||

CH1145R14 |

right+left

| Φ3-50 | Φ14.5×3×5 | 26 | twenty three | 74 | 16 | 14 | 99 | eat 14.53

|

CH1145R16 | 16 | |||||||||

CH1215R20 | Φ5-250 | Φ21.5×5×8 | 39 | 36 | 114 | 25 | 20 | 149 | eat 21.55 | |

CH1215R25 | 25 | |||||||||

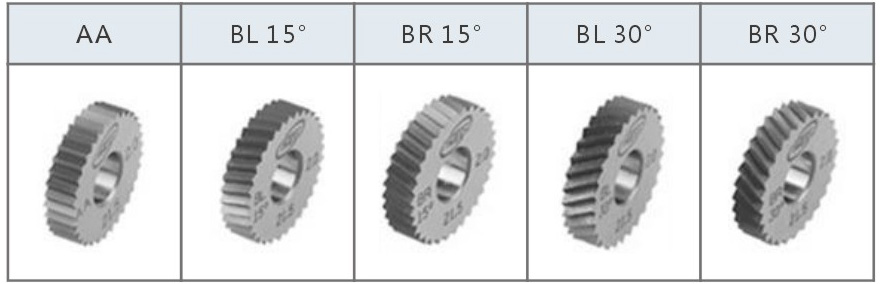

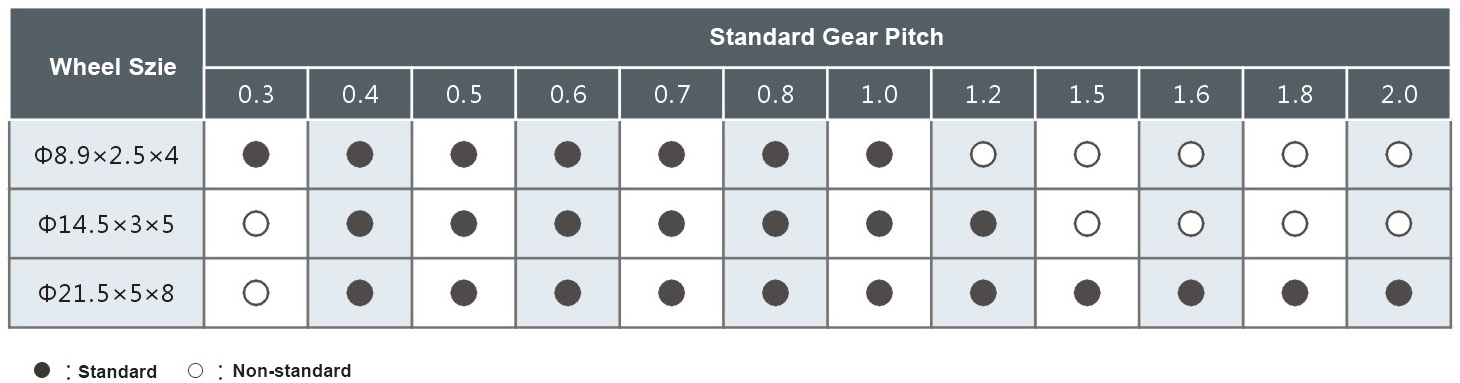

wheel size

Use of cutting knurling tools

1. Clamp the tool into the tool holder, adjust the center height of the tool, and ensure the center position of the workpiece.

2. Press the knurled wheel close to the outer diameter of the workpiece, adjust the two rollers, and the width of the entire shaft is completely attached to the workpiece.

3. When the knurling starts, it is about 1/2 of the tooth pitch and about 1/3 of the wheel width.

4. After the molding is completed, start the Z-axis feed.

5. If the tooth shape is wrong, it can be adjusted by adjusting the axial direction of the tool holder.

6. Use a larger cutting fluid to remove iron filings.

-

2D/3D/4D/5D U drill with WCMT indexable drill tool inserts.

-

Synthetic diamond grinding wheel for industrial machine tools

-

ZCCCT Carbide Milling Cutter APMT1135PDR YBG205 PVD Coated Carbide Milling Cutter Insert For Metal Processing CNC Tools

-

ZCCCT Tungsten Carbide Grinding Field APMT1604PDR P20M Grade for Lathe Cutting Tools

-

Premium rifle broach push button

-

Improve a variety of high-quality stable cutting drilling anti-break sharp tool drill bits

-

0.3-3.0 Super Straight Spinners, Spinner Wheels, Spinner Knife Kits

-

BKEA Carbide CNC Flat End Mill Cutter Tool Aluminum Stainless Steel Copper Processing Machine Spare Parts

-

3D/5D/8D Interchangeable Head Center Spade Cutting Tool Crown Drill Body

-

PENTA Precision Ground Long Life Black and Silver CNC Cut Pentagram Slotting Tool Holder

Other Products

-

$300.00 / piece

$300.00 / piece -

$140.00 / piece

$140.00 / piece -

$305.00 / piece

$305.00 / piece -

$375.00 / piece

$375.00 / piece -

$379.80 / set

$379.80 / set -

$210.00 / piece

$210.00 / piece -

$302.00 / piece

$302.00 / piece -

$365.60 / set

$365.60 / set -

$192.80 / piece

$192.80 / piece -

$450.00 / piece

$450.00 / piece