High Quality 3200*8mm hydraulic bender machine/4 axis CNC Press Brake

-

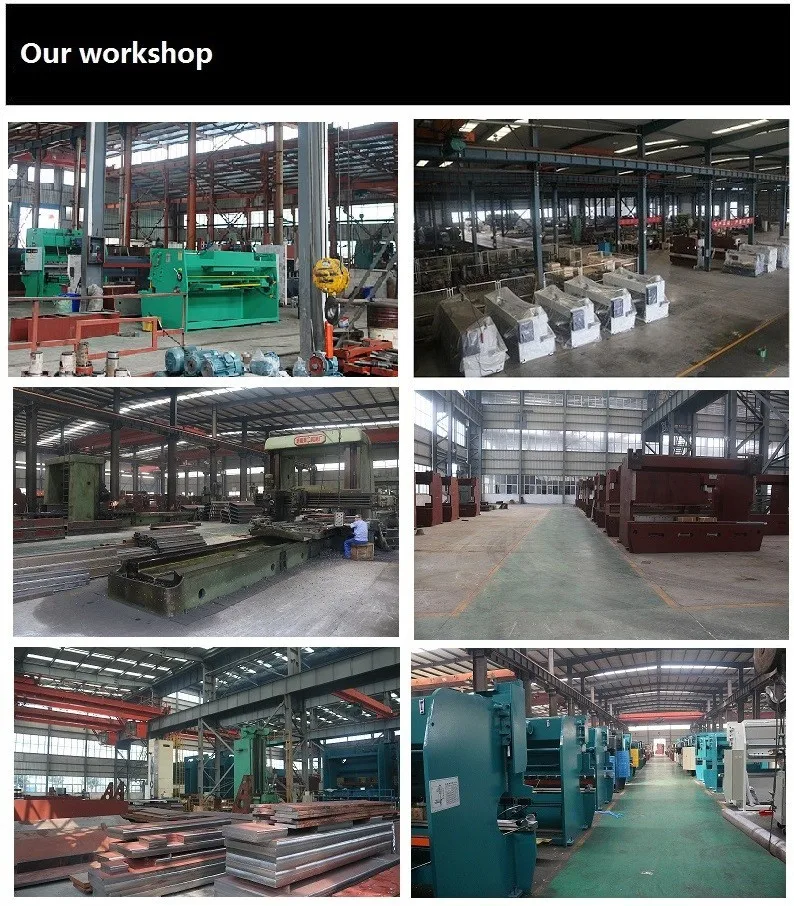

Supplier: Maanshan Dama Machinery Manufacturing Co., Ltd. -

Region: Anhui, China -

Contact: Mr mark Zou -

Price: $3000.00 /set -

Min. Order: 1 set

| Length of Working Table (mm): | 3200; | Local Service Location: | Egypt,Canada,Turkey,United Kingdom,United States,Italy,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Spain,Thailand,Malaysia,Australia,Morocco,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Uzbekistan; |

| Column spacing: | 2560mm; | Extra Services: | Heat Treating; |

| Nominal Pressure (kN): | 1250 kN; | Place of Origin: | Anhui China; |

| Throat depth: | 320mm; | Worktable length: | 3200; |

| Material / Metal Processed: | Brass / Copper,Stainless Steel,ALLOY,Carbon Steel,Aluminum; | Packaging Detail: | hydraulic press brake packing in bulk covered with plastic paper,standard packaging; |

| Slider stroke: | 100mm; | Key Selling Points: | Easy to Operate; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company,metal bending; | Throat Depth (mm): | 320; |

| After Warranty Service: | Online support,Spare parts; | Max.openging height: | 350mm; |

| Width of Working Table (mm): | 200; | Warranty: | 2 years,2 Years; |

| Slider Stroke (mm): | 200; | Brand Name: | DAMA press brake; |

| Machine Type: | Synchronized,Press Brake; | Supply Ability: | 60 Set/Sets per Month at least 60 sets hydraulic press brake per month; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Weight (KG): | 6000; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support,Engineers available to service machinery overseas; | Showroom Location: | None; |

| Certification: | ISO 9001:2000; | Motor Power (kw): | 7.5 kw; |

| Condition: | New; | Main motor power: | 7.5KW; |

| Port: | FOB shanghai China; | Automatic Level: | Fully Automatic; |

| Automation: | Automatic; |

High Quality 3200*8mm hydraulic bender machine/4 axis CNC Press Brake

Full back guage and side safety fenc

back gauge with high accuracy ball bearing screw and linear guild rail, CNC stop finger,with servo motor

CNC back gauge with R X Z axes, control system CT12 Delem DA52S DA56S DA66T

with Siemens motor & Bosch valve provide high working performance

CNC system optional:

DA41 DA52 DA66T Estun E21 etc

Features

1.All Steel Welded, Vibration eliminate stress, high mechanical intensity, good rigidity.Hydraulic upper

transmission, steady and reliable.

2. Mechanical stop dog, synchronization in twist axis, high precision.

3.Back gauge distance, upper ram stroke can be adjusted by motor-drive,manual operation micro-adjust

equipment, numerical display.

4.WE WORKTABLE full deflection compensation

Basic Main Components

1.NC display: Korea

2 Main Seal: PARKER

3.Main electronic element: Siemens/Schneider

4 Main Motor

5 Group valev

6.Conjugate internal gear pump

7.Back gauge

8.Mould

9.Oil cylinder

10.Front Plate Feeding will be equipped

11.Free charge Standard Upper and Down Mould

Main Character and Function

All the components of the machine are designed under the instruction of the Computer aided design and software of CAD/CAE/CAM to fully guarantee the intensity and rigidity of all the components.

The whole body under total wielded, thickness and reliable in machine body with high-rigidity and good in shock absorption reduction.

The machine structure are composed by body frame, working table, slide block, main cylinder and backgauge.The advantage design and produce style can ensure the machine usage and high precision.The main produce procedure as below(all process under strictly inspection)

Plate stock----physical and chemical inspection----Plate Pre-treatment (Rust-Cleaning) --- CNC flame Cutting-- Cutting the welded joint----Group Welding----Gas Shielded Welding---Ageing treatment----Milling Planer working----The Assembly of finished products

The machine body, Slide Block, Working table and other main components are under one time clamping of large landing boring and milling machine to ensure several geometric accuracy of the main machine.

The machine is greatly enhanced in anti-torque and electronic load resistance. Machine can normally work in full loaded situation. Working table, Upright Column, Crossbeam and Ram are good and high in design rigidity. Little deformation between the working table and ram when work to guarantee good straightness and uniformity in angle.

Machine’s main components under guaranteed quality or trustable company

The motor and electronic system elements are all composed from Siemens or Schneider

Dies can be designed under clients’ requirement.

Oil pump can be used from China chengjie enterprise who is used in China’s Aircraft industry.Or we can use Germany ECKERLER enterprises.

The seal will be from USA Parker or Japan Valqua company.

The hydraulic system and valve optional Germany BOSCH company.

The security protection equipment: We equipped protect fence to avoid any penetration inside and foot controller with emergency control button

-

Manual or pneumatic table stainless steel sheet metal / sheet metal bending machine / plate bending machine

-

DAMA TP10 Hydraulic Press Brake Large Heavy Duty CNC Controller Hot Selling Press Brake

-

CAC-75W hydraulic angle steel bending machine

-

AH Press Brakes for (Manual, Hydraulic, NC Hydraulic, Manual Folding Machine, Power)

-

2022 European high standard low cost MB8 series 200Tons/3200 CNC bending machine for sale

-

3KW Plate Bending Machine Hydraulic Multifunctional Steel Plate Bending Machine

-

Manual Sheet Bending Machine Hydraulic Bending Machine Metal Bending Machine

-

(W1.0X610B, W1.0X915B, W1.5X1220Z ) small handbrake/disc & box brake with CE, best price

-

Tool molds on bending machines, press blades on bending machines

-

Hot selling hydraulic new bending machine sheet metal bending machine 80t 3000 4000 6000

Other Products

-

$8000.00 - $9300.00 / set

$8000.00 - $9300.00 / set -

$498.00 - $999.00 / set

$498.00 - $999.00 / set -

$499.00 / set

$499.00 / set -

$3000.00 - $5000.00 / set

$3000.00 - $5000.00 / set -

$2109.00 / set

$2109.00 / set -

$500.00 / set

$500.00 / set -

$2000.00 / set

$2000.00 / set -

$2000.00 / set

$2000.00 / set -

$2000.00 / set

$2000.00 / set -

$500.00 / set

$500.00 / set