Waste Scrap Sheet Shearing Machine\alligator Scrap Metal Cutting Machine C Shears\q43 Series Crocodile Hydraulic Steel 55*55 Mm

-

Supplier: Maanshan Dama Machinery Manufacturing Co., Ltd. -

Region: Anhui, China -

Contact: Mr mark Zou -

Price: $2000.00 /set -

Min. Order: 1 set

| Packaging Detail: | scrap metal shearing machine Packing in bulk covered with plastic paper,standard packaging.optional wooden case. or scrap metal shearing machine packing as your requirements.; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pump; |

| Weight (KG): | 4000; | Color: | optional; |

| Rated Power: | 22kw; | Video outgoing-inspection: | Provided; |

| Blade length: | 1000mm; | Machinery Test Report: | Provided; |

| After-sales Service Provided: | Free spare parts,Online support,Video technical support,Field installation, commissioning and training,Field maintenance and repair service; | Max.cutting Size: | 55*55 mm; |

| Showroom Location: | Egypt,Italy,Peru,Indonesia,Pakistan,India,Russia,Spain,Thailand,Kenya,UAE,Colombia,South Africa; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Type: | scrap metal shearing machine; | Power (kW): | 18.5; |

| Max.cutting Force: | 2000kn; | Local Service Location: | France,Germany,Viet Nam,Peru,Saudi Arabia,Indonesia,Pakistan,India,Russia,Spain,Thailand,Japan,Malaysia,Morocco,Argentina,South Korea,Chile,Colombia; |

| Motor: | 22kw; | System: | Hydraulic; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Condition: | New; |

| Shearing Frequency: | 6-10times/min; | Warranty: | 2 years; |

| Material / Metal Processed: | Brass / Copper,ALLOY,Carbon Steel,Aluminum,stainless steel; | Supply Ability: | 50 Set/Sets per Month scrap metal shearing machine; |

| Payment Terms: | L/C,Western Union,D/P,T/T,MoneyGram,scrap metal shearing machine; | Key Selling Points: | Long Service Life; |

| Port: | scrap metal shearing machine FOB Shanghai or other ports in China. scrap metal shearing machine CIF your ports.; | Warranty of core components: | 1 Year; |

| Place of Origin: | China; | Marketing Type: | Ordinary Product; |

Waste scrap sheet shears\ Q43 series crocodile hydraulic steel shearing machine\ alligator scrap metal cutting machine

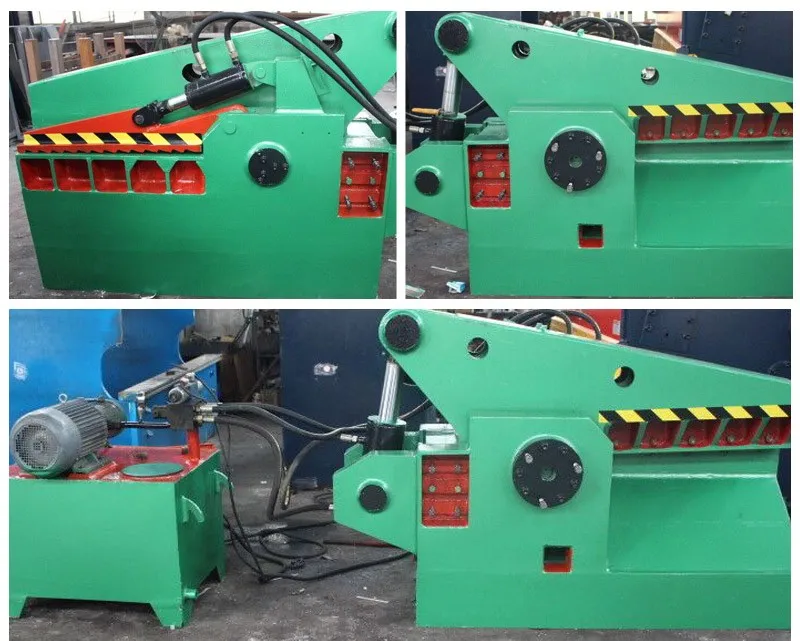

Photo of scrap metal shearing machine in our factory:

1. Q43 scrap metal shearing machines are applied in recyling companies ,automobile dismantling

plants,smelting and casting industry to cold shear all shapes of profile steels and all kinds of metals into qualified furnaces.

2. Whole steel structure and vibration to eliminate internal stree . Good strength and rigidity,hydraulic-driven,stable and reliable; No fang bolts are needed for installation;

3. Diesel engine can be used as power when electrical power is unavailable; length of the blade normall size 600mm,700mm,800mm,1000mm,1200mm,1800mm etc. and also can produce as your requirements.

4. scrap metal shearing machine shear force ranges in ten grades from 63T to 630T, which can meet users with different requirements.

5. Compared with the mechanical transmission type cutting machine, the equipment has the advantages of small volume, light weight, low inertia, low noise, smooth operation, easy operation, flexible operation, large shear section and easy adjustment of scissors. It is safe to operate and easy to realize overload protection.

6. Crocodile scrap metal shearing machine are suitable for cold cuts of scrap metal with various cross sections. All kinds of steel in the rolling mill are cut and cut. The machine has a quick installation, and the cutting speed is doubled. Improve the efficiency of 50%.

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

Technical parameters of scrap metal shearing machine:

| Type | Q43-63T | Q43-100T | Q43-120T | Q43-160T | Q43-200T | Q43-250T | ||||||

| Steel section | scrap size | No. | No. | No. | No. | No. | No. | |||||

| Round steel | φ35 | 1 | φ45 | 1 | φ50 | 1 | φ55 | 1 | φ65 | 1 | φ70 | 1 |

| Square steel | 30x30 | 1 | 40x40 | 1 | 45x45 | 1 | 50x50 | 1 | 65x65 | 1 | 70x70 | 1 |

| Angel iron | 80x80x4 | 2 | 100x100x6 | 2 | 110x110x8 | 2 | 110x110x8 | 2 | 110x110x10 | 4 | 110x110x4 | 4 |

| Channel bar | 80x60x4 | 1 | 100x80x6 | 1 | 120x100x8 | 1 | 120x100x8 | 1 | 120x100x14 | 1 | 120x100x16 | 1 |

| I steel | 80x80x6 | 1 | 100x100x8 | 1 | 110x110x10 | 1 | 110x110x10 | 1 | 110x110x10 | 2 | 110x110x14 | 2 |

| Steel | 20x50 | 1 | 20x100 | 1 | 20x120 | 1 | 20x300 | 1 | 20x500 | 1 | 25x600 | 1 |

|

Model |

Max.cutting force (ton) |

Blade length (mm) |

Max.cutting size (mm) |

Shearing frequency (times/min) |

Motor (kw) |

| Q43-63/600 | 63 | 600 | 30x30 φ35 | 8-12 | 7.5 |

| Q43-63/800 | 63 | 800 | 30x30 φ35 | 8-12 | 7.5 |

| Q43-100/600 | 100 | 600 | 35x35 φ40 | 8-12 | 11 |

| Q43-100/800 | 100 | 800 | 35x35 φ40 | 8-12 | 11 |

| Q43-120/600 | 120 | 600 | 45x45 φ50 | 8-12 | 15 |

| Q43-120/800 | 120 | 800 | 45x45 φ50 | 6-10 | 15 |

| Q43-160/800 | 160 | 800 | 55x55 φ55 | 6-10 | 18.5 |

| Q43-200/800 | 200 | 800 | 55x55 φ63 | 6-10 | 22 |

| Q43-200/1000 | 200 | 1000 | 55x55 φ63 | 6-10 | 22 |

| Q43-250/1000 | 250 | 1000 | 63x63 φ70 | 6-8 | 2x15 |

| Q43-250/1200 | 250 | 1200 | 63x63 φ70 | 6-8 | 2x15 |

| Q43-315/1000 | 315 | 1000 | 70x70 φ80 | 6-8 | 2x18.5 |

| Q43-315/1200 | 315 | 1200 | 70x70 φ80 | 6-8 | 2x18.5 |

| Q43-400/1200 |

400 |

1200 | 80x80 φ90 | 5-6 | 2x22 |

| Q43-400/1500 | 400 | 1500 | 80x80 φ90 | 5-6 | 2x22 |

| Q43-500/1200 | 500 | 1200 | 90x90 φ100 | 4-6 | 2x22 |

| Q43-500/1600 | 500 | 1600 | 90x90 φ100 | 4-6 | 2x22 |

Safety operation rules:

1. crocodile scrap metal shearing machine should be operated by the designated persons. Others can not be used arbitrarily without training.

2. before driving, check whether the parts are normal and whether the fasteners are solid.

3. unannealed steel, cast iron, soft metal parts, too thin pieces, work pieces of less than 100 millimeters in length, and work pieces that exceed the length of scissors are prohibited from shearing.

4. when operating, the body is not allowed to approach the transmission part and knife edge of the equipment, and the safety of the surrounding personnel should be paid attention to, so as to prevent the material from rising and hurting people. When cutting, the material should be cut near the edge of the knife as far as possible.

5.When cutting short material, hand-held workpiece is prohibited. The clamp should be used.

6. when the scrap metal shearing machine operate, the operator shall not leave the post without authorization. When the work is completed or the post is temporarily left, the power supply should be cut off. At the same time, the machine should not be repaired or touched by hand, and the hand or foot is strictly prohibited to press the material in the material box.

7. the lubricating parts of crocodile scrap metal shearing machine should be lubricated at least once per shift according to the requirements.

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

Photo of scrap metal shearing machine:

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

Details of scrap metal shearing machine:

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

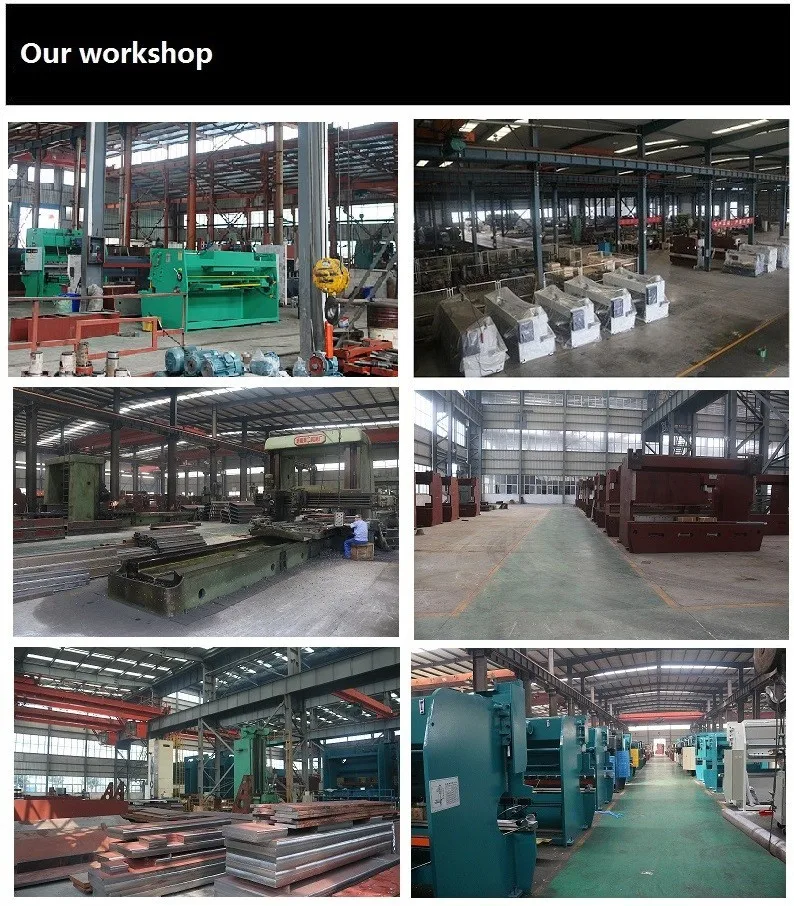

Producing scrap metal shearing machine:

Our scrap metal shearing machine,using new metal plate material, not scrap plate.

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

Producing scrap metal shearing machine:

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

Inside parts of scrap metal shearing machine:

| scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine | scrap metal shearing machine |

our scrap metal shearing machine painting in environmental spray booth

scrap metal shearing machine working

Feedback from user of scrap metal shearing machine:

|

|

-

Scrap Metal Cutting Machine Hydraulic Shear Machine Hydraulic Metal Alligator Shears

-

Keshang Y10Y-1300T automatic hydraulic gantry shearing machine

-

Hydraulic Scrap Metal Baler Scrap Metal Ferroalloy Recycling Machine Q91y-1000W Gate Shearing Machine

-

Efficient Portable Electric Fishtail Machine Iron Art Hot Rolled Metal Fishtail Forging Equipment

-

BSGH 220V small wire crushing granulator cable wire recycling machine

-

Best Selling Horizontal Container Shears

-

Dinghua Recycling Equipment Scrap Automobile Shearing Machine

-

Hot selling European hydraulic crocodile shears AS-630 widely used in scrap metal recycling market

-

High quality hydraulic metal shears AS-60 for cutting various steel and metal

-

Alligator Hydraulic Scrap Metal Rebar Shearing and Cutting Machine for Scrap Aluminum/Copper Scrap Processing Equipment

Other Products

-

$8000.00 - $9300.00 / set

$8000.00 - $9300.00 / set -

$498.00 - $999.00 / set

$498.00 - $999.00 / set -

$499.00 / set

$499.00 / set -

$3000.00 - $5000.00 / set

$3000.00 - $5000.00 / set -

$2109.00 / set

$2109.00 / set -

$500.00 / set

$500.00 / set -

$2000.00 / set

$2000.00 / set -

$2000.00 / set

$2000.00 / set -

$500.00 / set

$500.00 / set -

$3000.00 / set

$3000.00 / set