Dis-solvable Hydraulic Fracture Packer Bridge Plug for High Deviated Well

-

Supplier: Chongqing Weiyun Technology Development Co., Ltd. -

Region: Chongqing, China -

Contact: Mr YX Liu -

Price: $0.10 /piece -

Min. Order: 1 piece

| Max setting force: | 140KN; | Applicable Industries: | Shale gas exploration, horizontal wells; |

| Supply Ability: | 1000.0 Piece/Pieces per Month; | Rated working pressure difference: | 35/50/70MPa; |

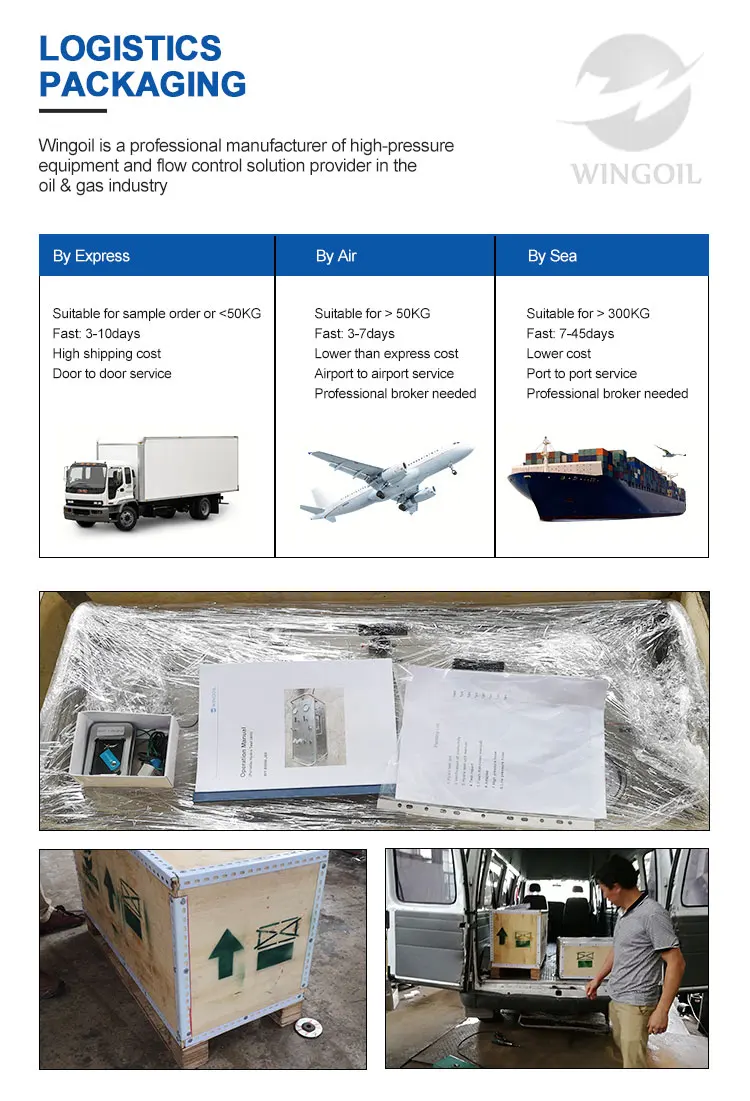

| Max test pressure: | 60-90MPa; | Packaging Detail: | Plywood carton for air freight and ocean freight; |

| After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; | Model Number: | WY-453; |

| Type: | Downhole Tool; | Max working temperature: | 120, 150 ° C; |

| Releasing dissolution time: | 5-7 days; | Local Service Location: | None; |

| Max releasing force: | 140KN; | Min setting force: | 100KN; |

| Weight: | 6.1Kg; | Payment Terms: | L/C,T/T,Western Union; |

| Warranty: | Unavailable; | Showroom Location: | None; |

| Medium: | 0.5-2% KCL salt solution; | Port: | Chongqing; |

| Blocking period: | 36 hours; |

|

Model: WY-453 No need to drill after fracturing, No residue, Full-bore production flow path 1. Self-made multi-strength soluble metal manufacturing, dissolution time on demand transformation. The main body of our company's soluble bridge plugs is made of self-developed multi-strength soluble magnesium metal composite. After the core material composite application, the dissolution time of the whole machine is completely consistent, no residue, no toxicity, according to the on-site water quality and work. It is necessary to adjust the formula at any time to change the unique advantage of dissolution time.

|

| 1: Solved the problem of material strength stability at high temperatures; 2: The maximum compressive strength of high temperature is adjustable from 550 to 650 MPa; 3: The modulus of elasticity is about 70 ~ 80 KN / mm2; 4: It can be used for sliding sleeves with a range of 1/10 in. |

|

2:Self-developed high-strength degradable rubber cylinder for quick release of plugging The fully soluble bridge plug rubber cylinders are all made of self-developed high-strength degradable materials. Since the materials are uniquely produced by our company and have the advantages of effective control of degradation start-up time and degradation time, six temperature series products have been formed. |

Partial sol-tube performance parameter table

|

Type |

RJ001-A |

RJ001-B |

RJ001-C |

RJ001-D |

|

Stable time h |

48 |

48 |

48 |

48 |

|

Degradation time (days) |

15 |

15 |

15 |

15 |

|

Working temperature °C |

60-80 |

80-100 |

100-120 |

120-150 |

Specifications and models

|

Model |

Outer Diameter(mm) |

Inner Diameter(mm) |

Length(mm) |

Operating Temperature(℃) |

Pressure Difference(MPa) |

Casing Inner Diameter(mm) |

|

WY453-110 |

110 |

40 |

680 |

120/150 |

70 |

118-124 |

|

WY453-105 |

105 |

40 |

680 |

120/150 |

70 |

114-118 |

|

WY453-95 |

95 |

30 |

680 |

120/150 |

60 |

114-115 |

|

WY453-95 |

95 |

30 |

680 |

120/150 |

70 |

108-110 |

|

WY453-85 |

85 |

22 |

650 |

120/150 |

60 |

114-115 |

|

WY453-85 |

85 |

22 |

670 |

120/150 |

70 |

102-104 |

|

WY45R92-70 |

92 |

30 |

595 |

40-150 |

70 |

100-110 |

|

WY45R95-70 |

95 |

36 |

640 |

40-150 |

70 |

103-116 |

|

WY45R102-70 |

102 |

40 |

595 |

40-150 |

70 |

110-122 |

|

WY45R110-70 |

110 |

48 |

595 |

40-150 |

70 |

118-136 |

Mechanical properties of partially soluble metal materials

| Type | KR001-A | KR001-B | KR001-C | KR001-D |

| Compressive strength(MPa) | 300 | 380 | 480 | 600 |

| Tensile strenth(MPa) | 310 | 390 | 470 | 520 |

| Working temperature(℃) | 180 | 180 | 180 | 180 |

-

Swell Packer Innova Oil Tools K344 Swell Packer Rubber Packer

-

API downhole equipment drag block tubing anchor/catcher EUE connection for pipe pump

-

Oilfield API Packager

-

5-1/2" 7" 9-5/8" Mechanical Kit Double Jacket Packer RTTS Packer

-

High pressure grouting machine

-

API 11D1 oil field downhole tool double rubber cup packer casing packer

-

RSB search tool

-

7.5/8" API11D1 Double Port 10000 PSI Retrievable Hydraulic Packer

-

High quality oil well cup packer

-

Y241 steel packer oil well drilling oil packer oil packer

Other Products

-

$1500.00 / set

$1500.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$0.10 / piece

$0.10 / piece