Lower Price Cnc Gear Cutting Hobbing Machine Manufacturers

-

Supplier: Jiangsu Tiptop Machine Tools Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Ethan Lau -

Price: $14000.00 /set -

Min. Order: 1 set

| Gear Precision: | Grade 7; | Supply Ability: | 50 Set/Sets per Month; |

| Gear Capacity: | Spur Gear, Work Gear, Helical Gear, Bevel Gear; | Max. Height of Workpiece: | 250-1800mm; |

| Key Selling Points: | Competitive Price,High accuracy; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Gear Material: | Steel, Cast Iron, Copper; | Hob Cueer: | Available in stock; |

| Local Service Location: | None; | Dimension(L*W*H): | As per the model; |

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Retail,Construction works ,Energy & Mining,Gear factory; | Working Table Diameter: | 510-4500mm; |

| Weight (KG): | 4800; | Payment Terms: | L/C,T/T,Western Union; |

| Voltage: | 220/380/415/600V; | Type: | Gear Hobbing Machine; |

| Controller: | Normal or CNC; | Modulus: | 8mm-40mm; |

| Certification: | CE,ISO,BV,SGS; | Showroom Location: | None; |

| Keyword: | cnc gear cutting machine; | After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; |

| Place of Origin: | Jiangsu China; | Packaging Detail: | cnc gear cutting machine : Wooden Case; |

| CNC or Not: | Normal; | Brand Name: | LETIPTOP; |

| Max. Diameter of Workpiece: | 500-12500mm; | Condition: | New; |

| Power (kW): | 5.5; | Port: | Shanghai Port, China; |

| Warranty: | 2 years; |

Lower Price Cnc Gear Cutting Hobbing Machine Manufacturers

Product Application

LETIPTOP gear hobbing machine is fixed by vertical column and adopts the traditional layout of horizontally moving working table, suitable for processing cylindrical gears, worm wheel and short spline shaft in bulk, in package, or in single workpiece. The machine has the following characteristics:

1.Raised height for vertical column and increased stroke: The vertical column is made higher to enable processing of larger tooth width.

2.Service life of cutting tools is increased by electric tool leap. The longest stroke, such electric tool leap takes longer hob and greatly increases life the hob.

3.High precision and long service life: The machine adopts the worm gear of a high precision over five grade and uses bronze alloy material which is of high abrasion resistance, enabling long service life and steady accuracy.

4.Higher tool speed allowed: Rolling bearings replace the traditional bearings along the hobs to allow greater rotating speed of the tools.

5.Backlash balancing cylinder is involved as the tool post moves in the axial direction, effectively reducing the space between lead screws and eliminating vibration.

6.Convenient hydraulic powered structure reduces the non-cutting time as well as the times to use the cutting tools.

Main Features

♦Interactive PLC touch screen offers easy access to auto and manual operating modes.

♦System diagnostics and multiple language capability.

♦Standard clockwise bending direction.

♦Fully hydraulic clamping on clamp die and pressure die.

♦Drop-way hydraulic clamping.

♦Direct acting hydraulic pressure die with adjustable speed valve.

♦Maximum 100 sets of program storage,Maximum 32 bends for each program.

♦With Independent programmable speeds Y, B, and C axes.

♦Programmable material spring back settings for each bend angle.

♦Automatic release of tube prior to final bend.

♦Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor

♦Obtain quality repeatable bends in steel, stainless, aluminum, titanium and brass.

♦Foot Pedal Cycle start.

♦With Air Cooling System.

♦One set of Tooling for Draw Bending.

♦Wiper die Bracket.

♦1 Mandrel Rod.

♦Operation and Maintenance Manual.

♦Tool Box with Adjusted Tools.

♦Electric: As required (3 phase 220V or 380V or 415V...)

▶ ABOUT US

Jiangsu TIPTOP Machine Tools Co., Ltd. is a well known worldwide manufacturer of machines for sheet metal working, such as Hydraulic Ironworker, Hydraulic Shearing Machine, Press Brake, Plate Rolling Machine and Section Bender utilizing the most recent technologies and constantly refined by our design engineers to meet the most demanding market requirements for flexibility.

view more>>

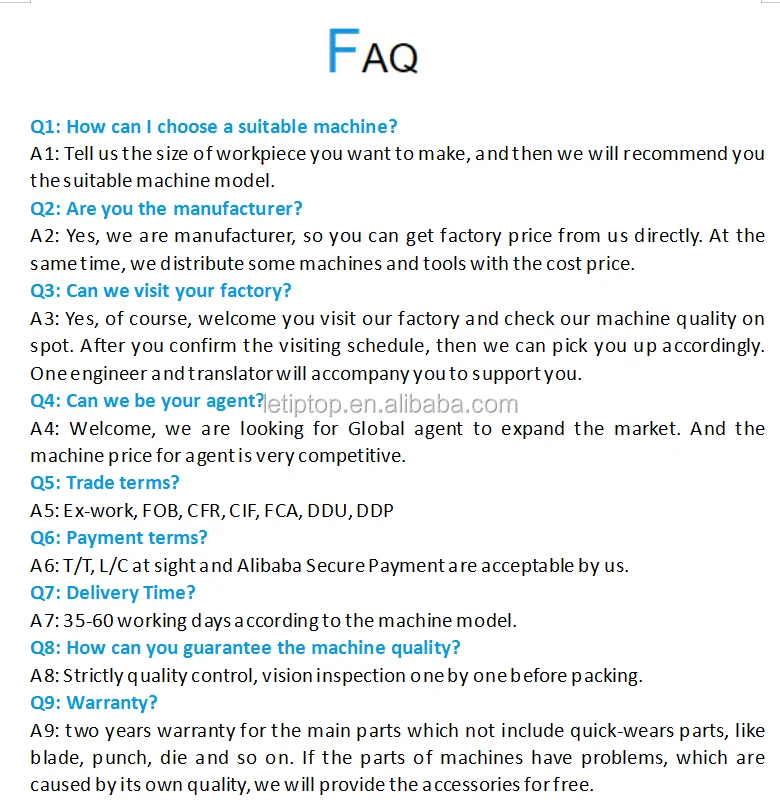

Pre-Sales Service

* Inquiry and technology support

* Technical documents

All labels on machines and lay-out drawings, Electrical diagram, Operation Manual, will be in English. The seller should send all necessary files to the buyer since the third week since project execution. All documents in hard copies should be also shipped with machines together.

* Quantity and quality guarantee

a.Quantity/Quality Discrepancy to destination port during transportation:

In case of quality/quantity discrepancy to destination port in transportation, the buyer should file claim within 30 days after the arrival of the goods at port of destination. The seller will not be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.

b.Guarantee period and after-sales services: 13 months since date of bill of lading

During this guarantee period, the seller will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, the seller will provide the buyer spare parts at cost price.

* View our Factory.

After-Sales Service

* Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. The buyer will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 per day for each engineer.

d. Engineer will give free training lessons to labors in buyer's factory.

*The seller will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

*2 years quality warranty

-

China Y3180 CNC gear hobbing machine for sale

-

Special-shaped gear hobbing machine CNC gear processing machine tool processing equipment

-

CNC spline shaft milling machine (horizontal gear hobbing machine) schedule

-

Automatic gear hobbing machine 3180 gear hobbing machine phfauter gear hobbing machine

-

YD3132CNC Ten Axis CNC Dry Metal Rotary Cutting Machine High Precision Factory Price Spindle

-

CNC Spindle Milling Machine (Horizontal Gear Cutting Machine)

-

200mm gear shaper YKD5120D

-

YK3132 CNC gear cutting machine for sale

-

Y5150K Gear Shaper Universal Gear Shaper Manual

-

Y3150 gear hobbing machine large module hobbing machine for sale

Other Products

-

$10300.00 / set

$10300.00 / set