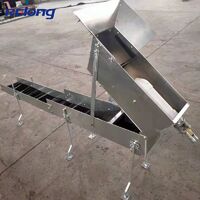

Low price gold shaking table for sale

-

Supplier: Shanghai Vostosun Industrial Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Wang Jing -

Price: $987.00 /set -

Min. Order: 1 set

| Bed surface Water quantity(t/d): | 80-150; | Bed surface Portrait obliquity (%): | 1.4; |

| Supply Ability: | 80 Set/Sets per Month Low price gold shaking table for sale; | Dimension(L*W*H): | 4450X1855X1546mm; |

| Bed surface Horizontal obliquity (°): | 2.5-4.5; | Warranty: | 1 Year; |

| Place of Origin: | Shanghai China (Mainland); | Port: | Qingdao port, Shanghai port, Ningbo port or as request; |

| Stroke(mm): | 16-22; | Voltage: | Clients Local Standard; |

| Brand Name: | VOSTOSUN; | Feeding amount(t/d): | 30-60; |

| Production Capacity: | 1 T/H; | Payment Terms: | L/C,T/T,Western Union,MoneyGram,Cash, RMB; |

| Bed surface length ratio: | 2.6; | Frequency ( f ): | 45-48; |

| Condition: | New; | Weight: | 1100kg; |

| After-sales Service Provided: | Video technical support,Free spare parts,Online support,Field installation, commissioning and training,Field maintenance and repair service; | Feeding thickness(%): | 25-30; |

| Type: | Gravity Separator; | Applicable Industries: | Construction works ; |

| Packaging Detail: | Low price gold shaking table for sale: Standard packing, spare parts will put into the wooden cases then transport by the container, big model will be nude packing. Each machine and spare parts will have a special nameplate in customer local language...; | Max. Feeding size(mm): | 2; |

| Certification: | ISO9001 CE BV SGS; | Concentrating area(m2): | 7.6; |

Low price gold shaking table for sale

Shaking Table, which is also called concentrator table, is a gravity dressing machine. It is widely used for separating fine particles such as tin, tungsten, gold and silver, lead, zinc, tantalum, niobium, iron, manganese, titanium, ferrotitanium and coal.

Main Features

High concentration ratio, high dressing efficiency and simple operation

Can harvest the final concentrate and final tailings only for once

High cost performance ratio

Low energy consumption & long working life

Easy installation & convenient to manage

Convenient stroke adjustment

Three different decks to choose

Different granules inside the pulp have different density.When the pulp reached the table surface from the feeding tank, effected by the gravity force, water flow force, the inertial force and friction force which comes from the reciprocating movement of the table surface, the granules in it will be classified and moved to the different direction: the high density one will go front and drop from the concentration end, the gangue will go to the tailing side, and the middles will be re-concentrated on the shaking table.

How to choose the right model of shaking table?

To Choose the shaking table model according to the Max feeding size, the feeding amount and plant area.

Max feeding size <2mm, coarse sand deck shaking table

Max feeding size <0.5mm, fine sand deck shaking table

Max feeding size <0.1mm, slime deck shaking table

The smaller the feeding size is, the less feeding amount will be.

If the plant area is not enough, we can use double-decked shaking table.

Pre-Sales Service

1>. Select proper equipment model;

2>. Design and manufacture products according to clients' special requirement;

3>. Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

4>. Make sure goods prepared within delivery time;

5>. Pre-check and accept products ahead of delivery;

6>. Prepare documents required to help customer pass customs clearance.

7>. Help clients to make Project evaluation and feasibility analysis and draft solving plans.

After-Sales Service

1>. Assist clients to prepare for the first construction scheme;

2>. Install, debug and examine the equipment;

3>. Train technical personnel the first-line operators;

4>. Provide technical exchanging

5>. Offer spare parts at a best price for long term.

Ball Mill

99.8% Response Rate

Wet pan mill

99.8% Response Rate

Flotation Separator

99.8% Response Rate

Send Message or Chat Now for Latest price!!!

Tips: please tell me your material and capacity to become our quality clients which will have 2%-10% discount

please tell me the following questions, so we can send you accurate quotation with additional discount:

♥ What's the raw materials you want to process(such as gold ore, iron ore...)?

♥ What is capacity you want tons per hour? such as 1TPH, 5TPH, 10TPH, 20TPH, 50TPH.....

♥ Your email address or phone number

♥ Other requirements. (We are professional manufacturer of mining equipment(jaw crusher, impact crusher, cone crusher, sand making machine, mobile crushing plant, vibrating feeder, vibrating screen, belt conveyor, ball mill, flotation machine, shaking table, magenetic separator, pan mill, raymond mill), concentrating machine; caravan, medical vehicle, road-show vehicle; loader, forklift, telescopic forklift.)

♥ Or you can contact me by Whatsapp: 0086 159 9311 5469

↓↓↓

-

4-piece set of Rive gold washing plate washing gold plastic plate with 4 pieces of gold panning

-

Screen Drum Concentrator Gold Sand Separator Lock Box Gold Mining

-

Alluvial gold mining equipment drum washing plant gold separator

-

Gold Sluice Straw Mat/Gold Wash Carpet/Gold Sluice Carpet

-

2022 hot sale gold panning grader gold pan gold pan gold pan kit at best price

-

Mobile Gold Mining Equipment Gold Separator For Sale

-

Small Portable Gold Panning Machine Light Gold Mining Machine

-

Gold electrolysis / electrolytic cell / automatic gold withdrawal

-

RL-2018 Gold Sluice Box High banker Sluice

-

100TPH Gold Trommel Screen Wash Plant Alluivial Gold Mining Machine

Other Products

-

$100000.00 / set

$100000.00 / set -

$36895.00 / set

$36895.00 / set -

$330000.00 / set

$330000.00 / set -

$150000.00 / set

$150000.00 / set -

$61470.00 / set

$61470.00 / set -

$36895.00 / set

$36895.00 / set -

$1100.00 / set

$1100.00 / set -

$100000.00 / piece

$100000.00 / piece -

$10000.00 / set

$10000.00 / set -

$36230.00 / set

$36230.00 / set