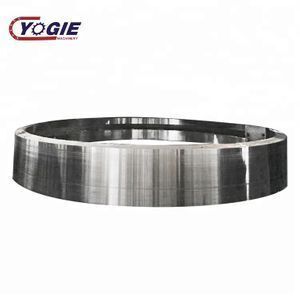

Custom Casting steel GS34CrMo4 cement kiln bandage riding rolling rotary kiln Tyre ring

-

Supplier: Luoyang Yujie Industry & Trade Co., Ltd. -

Region: Henan, China -

Contact: Ms Sara Cui -

Price: $10.00 /piece -

Min. Order: 1 piece

| Payment Terms: | L/C,D/P,T/T,Western Union; | Power(W): | Customized; |

| Certification: | ISO; | Place of Origin: | Henan China (Mainland); |

| After-sales Service Provided: | Online support; | Application: | rotary kiln,mining; |

| Standard: | DIN,JIS,ISO,GB; | Certification: | ISO9001; |

| Production Capacity: | Customized; | Warranty: | 1 Year; |

| Material: | alloy steel, casting steel; | Weight: | Customized; |

| Packaging Detail: | cement rotary kiln Tyre packing: plywood cases or as per customers' requirements; | Name: | rotary kiln Tyre ring; |

| Supply Ability: | 100 Piece/Pieces per Month cement rotary kiln Tyre; | Model Number: | Acoording to drawings; |

| Dimension(L*W*H): | Customized; | Size: | Custom; |

| Port: | Qingdao, Shanghai; | Brand Name: | YOGIE; |

| Voltage: | Customized; | Type: | mine machinery parts; |

| Condition: | New; |

material organization to processing the good quality. equipment.

production and assmbly.

Kiln tire is also called riding ring, is one of the main parts of rotary kiln equipment The kiln tyre can pass the all barrel gravity (include the gravity of refractory brick, internal device and material) to riding wheel, and make the barrel smoothly rotation on the wheel rotation, therefore the kiln tyre should have enough strength and durability At the same time, kiln tyre strengthen barrel radial stiffness so it should has enough rigidity.

Product name | Cement rotary kiln tyre |

Material | ZG45,ZG42CrMo,35CrMo |

Structure | Casting |

Process | Lathing, milling |

Max.diameter | 2900mm |

Max.length | 2900mm |

Max.tolerance | ±0.3 |

Application | Rotary kiln |

Type | According to drawings |

Package | Seaworthy packing |

Delivery time | 30-90 days |

Certification | ISO9001-2008 |

Products advantages

High strength &long life

The kiln tyre of rotary kiln with ZG45 and ZG42CrMO materials can guarantee the strength and toughness, so as to support the barrel.

Used advanced double medium quenching process, has strong adaptability

The kiln tyre has high quenching hardness and toughness and uniformity material by double medium quenching. It can be used to all kinds of bad working environment because of good wear resistance.

Simple structure and easy to adjust and maintenance

YOGIE is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts according to customer's request, including shafts, gears, sprockets, mining machinery parts, weldings, bearings, lime rotary kiln tyre etc.

The products are mainly used in the fields of mining, petroleum, cement, steel mill, power plant, sugar factory etc.

1. What is your terms of delivery?

A: FOB, CFR, CIF.

2. Can you produce according to the samples of lime rotary kiln tyre?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

3. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

LuoYang Yujie Industry&Trade Co.,Ltd

Address:Jianxi Industry Park, Luoyang city

Tel:0379-80882592

Fax:0379-65163600

web:www.yogiemachinery.com

-

Professional lime production line lime kiln lime production factory

-

China 100TPD lime kiln for lime production line factory

-

Supply 100-2000tpd cement production line cement machinery manufacturing plant

-

Professional mini cement plant, cement production line construction project

-

Efficient Concrete Mixer Cement Mixer Force Action Mixer JS750

-

4.0×60 lime equipment rotary kiln, cement plant rotary kiln, roller table rotary kiln

-

Ex-factory price of advanced technology of Great Wall Cement Plant

-

New type ball mill sliding shoe bearing

-

cement mill/clinker grinding station/cement grinding plant

-

6000tpd 42.5 Portland cement plant

Other Products

-

$600.00 - $800.00 / piece

$600.00 - $800.00 / piece -

$359.00 - $455.00 / piece

$359.00 - $455.00 / piece -

$900.00 - $1000.00 / piece

$900.00 - $1000.00 / piece -

$50.00 / piece

$50.00 / piece