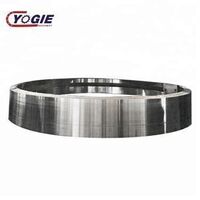

Forged steel ring gear/ball mill ring gear/kiln ring gear

-

Supplier: Luoyang Yujie Industry & Trade Co., Ltd. -

Region: Henan, China -

Contact: Ms Sara Cui -

Price: $1000.00 / 1 - 4 pieces

$950.00 / 5 - 9 pieces

$900.00 / >=10 pieces -

Min. Order: 1 piece

Product details

| Standard or non-standard: | non-standard; | payment terms: | L/C,Western Union,T/T,MoneyGram; |

| Package: | wooden box; | Packaging Preview: | ; |

| Supply capacity: | 100 tons per quarter rotary kiln spur gear; | Video external inspection: | if; |

| Surface treatment: | Turing, turning, grinding, milling; | Local service location: | not any; |

| brand: | yoga; | Heat treatment: | Quenching and tempering; |

| pressure angle: | customer; | Applicable industries: | Building materials stores, manufacturing plants, mechanical repair shops, construction works, energy and mining; |

| shape: | ring gear; | delivery time: | 30-60 days; |

| application: | Ball mill, cement mixer; | Material: | steel; |

| Origin: | Henan, China; | State of health: | new; |

| Module: | 5-200; | Packaging Details: | Plywood boxes or other suitable for sea transportation; |

| Processing: | forging; | Tooth profile: | helical gear; |

| Core Components Warranty: | 1.5 years; | Certification: | International Organization for Standardization; |

| After Warranty Service: | Video technical support, online support; | Showroom location: | not any; |

| standard: | GB JIS DIN ISI BS; | Core components: | ring gear; |

| Marketing Type: | Hot selling products in 2019; | port: | Qingdao, Shanghai; |

| Mechanical test report: | if; | product name: | Big ring gear/big gear; |

| OEM service: | yes; | Warranty: | 1.5 years; |

Why choose us

product description

Forged steel ring gear/ball mill ring gear/kiln ring gear

Gears, ring gears, and large ring gears are often used in mechanical transmission. They are mostly made of high-quality high-strength alloy steel with forged or cast structures, surface carburized or hardened, and gears have high bearing capacity and durability.In practical applications, it is widely used in high-speed heavy-duty machinery due to its characteristics of stable transmission, small impact, small vibration and low noise.thisOur company's large gears are carefully designed with high-quality raw materials.The cast rims for the gears are sourced from the most trusted and reliable suppliers in the field.Our quality experts inspect products at every stage of the manufacturing process against set international industry standards.

Our company can produce different types of ring gears and wheels such as spur gears, helical gears, herringbone gears, and ring gears according to customers' drawings and requirements.Our products are highly valued by customers for their superior design, dimensional accuracy, excellent strength and ease of use.Install.Different specifications can be provided according to customer requirements.

application

1. Rotary kiln

2.Rotary dryer

3. Ball Mill

4. metersMechanical transmission

The advantages of gears1. Large bearing capacity and long service life.2. High precision, large diameter and large modulus 3. Smooth transmission, small impact, small vibration and low noise

4.Easy installation

company advantage

1. We provide one-stop service from raw material organization to processing production and assembly 2. We have a professional engineer team and strict quality control system to ensure the quality of products.3. We have a number of CNC advanced equipment to ensure the accuracy of the product

Click here to send me an inquiry | ||||||||

Process flow

42CrMo, C45 ZG310-570 or other alloy steels can be used as raw materials by forging or casting methods according to customer requirements.Ultrasonic inspection will be performed to ensure the material is free of pores, holes and cracks.Measure forging dimensions, calculate machining allowances, and accurately estimate the number of cuts during turning.

Depending on the tooth type and module, the gears are hobbed on a gear hobbing machine or milled on a CNC milling and drilling rig.Other sizes are processed into finished sizes according to drawings.

Large non-standard teeth will be milled on CNC gantry milling and drilling rigs

traditional teeth will beHobbing on a hobbing machine

After finishing, surface hardening or carbonization is carried out to improve the hardness and wear resistance of the teeth.After surface hardening, we will check the hardness of the teeth.

We have perfect and strict quality management system and experienced inspectors to control product quality.The gears will be inspected strictly according to the drawings.

By air or sea, DHL/TNT/UPS/EMS etc.According to customer's request.

If you have any questions, please let us know at any time.

We will get back to you within 24 hours.Thanks!

Click here to send us an inquiry

Thanks!!!

about us

Luoyang Yujie Industry and Trade Co., Ltd. was established in 2004. It mainly designs and manufactures large mechanical parts and non-standard mechanical parts according to customer requirements, including shafts, gears, sprockets, mining machinery parts, welding parts, bearings, castings and forgings Wait.Products are mainly used in mining, petroleum, cement, steel mills, power plants, sugar factories and other fields.

All our equipment adopts advanced CNC machine tools, especially large CNC gantry milling and boring machines, CNC floor boring machines.CNC gantry milling and boring machine, equipped with a CNC machining center with the fourth axis, equipped with a CNC floor boring machine with the fourth axis and a rotary table, it can realize five-axis machining.Workpieces are not limited in size.It is suitable for processing large modules, large-size gears, boxes, and large non-standard parts.

Professional technical team, production team and assembly team to provide professional technical support.

We manufacture CNC equipment, so we have professional assembly technicians and motors.We can provide customers with one-stop service from raw materials, processing to final assembly.

Our company has a series of advanced equipment: XV6032, HXV4032, HXV3017, HXV2017CNC gantry boring and milling machine, TX130CNC floor boring machine, DVT-500, HK1600CNC vertical lathe, CK6136CNC horizontal lathe, etc., to ensure products with high machining accuracy and stable performance.

All tests are in line with ISO 9001 quality management system certification standards, supporting customers to entrust third-party inspections.

customer visit

Semi-automatic PET blow molding machine bottle machine bottle machine PET bottle making machine is suitable for producing various shapes of PET plastic containers and bottles.

Certificate

Customer Reviews

contact us

Address: Jianxi Industrial Park, Luoyang City, Henan Province

Tel: 0379-80882592

Fax: 0379-65163600

Website: www.yogiemachinery.com

Tel: 0379-80882592

Fax: 0379-65163600

Website: www.yogiemachinery.com

VIEW MORE

You may like

-

Non-standard custom-made heavy-duty large-module alloy steel segmented cast herringbone double helical cylindrical large ring gear

-

Isuzu accessories flywheel gear 8-97046366-0 8970463660 flywheel ring gear Isuzu NPR75 4HK1-TCS 4HF1

-

OEM Precision Metal Stainless Steel Ring and Pinion Planetary Gears for Reduction Boxes

-

High quality ABS ring sensor for truck components anti-lock brakes

-

Customized high-precision reducer ring gear and pinion planetary gear set

-

Custom ring for cement concrete mixer

-

Metalen AC220V-240V Widely GWS7-125 gears manufacturing machinery gear parts

-

High-quality suppliers Small machining planetary gear sets Steel power transmission parts Ordinary products

-

Custom Size High Quality Hobbed Inner Casting Heat Treated Inner Ring Gear

-

gearbox transmission parts Synchronizer Gear Fiat Palio Albea Marea1.3 Jtd OEM46767058

Other Products

-

$600.00 - $800.00 / piece

$600.00 - $800.00 / piece -

$359.00 - $455.00 / piece

$359.00 - $455.00 / piece -

$50.00 / piece

$50.00 / piece -

$10.00 / piece

$10.00 / piece