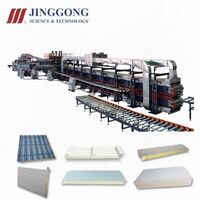

2 million annual output automatic bitumen waterproof membrane production line

-

Supplier: Shandong Yading International Trade Co., Ltd. -

Region: Shandong, China -

Contact: Mr Alan Lee -

Price: $100000.00 /set -

Min. Order: 1 set

| Application: | waterproof membrane production; | Operation Mode: | Semi-automayic and automatic; |

| Port: | Qingdao; | Top surface: | PE film/Sand/aluminum foil; |

| Place of Origin: | Shandong China; | Product name: | automatic bitumen waterproof membrane production line; |

| Delivery Detail: | Within 90 days after getting deposit.; | Payment Terms: | L/C,T/T,Western Union; |

| Capacity: | 2 million, 3 million, 5 million, 10 million; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Production thickness: | 2mm-5mm; | Coating: | SBS modified bitumen; |

| Color: | painted as your requirement; | Supply Ability: | 15 Set/Sets per Year; |

| Packaging Detail: | waterproof membrane machine of every part is carefully packed to avoid damaging during transportation; | Brand Name: | Yading; |

| Type: | Auto production line; |

2 million annual output automatic bitumen waterproof membrane production line

Bitumen Membrane (Bituminous Membrane) is widely used in industrial and civil buildings, such as, roof、 basement、toilet、bridge、park、swimming pool、tunnel for waterproof and moisture-proof. Bitumen is kind of hydrocarbon and is created naturally from crude oil. It is a useful carbon store and does not generate greenhouse gases. The membrane is therefore a sustainable way of storing carbon on the Earth's surface.

Bitumen-Mixed with rubber powder, talc powder. Meanwhile polymers are added to the bitumen such as APP (atactic polypropylene) a plastic additive that gives rigidity and tear resistance or SBS (styrene butadiene styrene) a rubber additive that gives more elastic benefits.

Why choose US?

1. Honest supplier to the worldwide buyers

2. Factory , disrec supplier, competitive price

3. Warm and Friendly service and guide

4. Small and big orders are welcomed from the world

5. 24 hours service for you

1. What is the loading time?

Within 90 days after getiting deposit

2. What is yout product warranty?

We guarantee the products customers receive are qualified. If there are any broken parts, please send us some detailed photos by email, and then we will send you the replacement parts according to actual conditions.

3. How about the trade term?

EXW, FOB, CNF, CIF are all ok.

4. How about the payment method?

30% T/T deposit +65% T/T before loading +5% T/T balance after testing machine

5. What is the Loading port?

Qingdao, China

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

Other Products

-

$100000.00 / set

$100000.00 / set