T-600GY Good Price Corner Rounding and Pre milling Functions High Efficiency Edge Banding Machine Automatic for Sale

-

Supplier: Foshan Leabon Machinery Company Limited -

Region: Guangdong, China -

Contact: Mr Daniel Liu -

Price: $19800.00 /set -

Min. Order: 1 set

| Brand Name: | LEABON; | Single package size: | 100X90X10 cm; |

| Power(W): | 16.9kw; | Warranty: | 1 Year; |

| Frequency Control: | Delta; | Single gross weight: | 30 KG; |

| A.C. Electric components: | Schneider; | After-sales Service Provided: | Online support; |

| PLC: | Delta; | Certification: | CE Certification; |

| Weight: | 2800kg; | Selling Units: | Single item; |

| Dimension(L*W*H): | 6840x900x1600mm; | Package Type: | T-600GY Edge banding machine automatic use PE Film Packing and fix into container with steel wire. Plywood package is also available against your request.; |

| Voltage: | 380v/220v; | Place of Origin: | Guangdong China (Mainland); |

| 7-inch Touch Screen: | Delta; | Applicable Industries: | Furniture Factory; |

| Cylinder: | Air tac; | Condition: | New; |

| Working methods: | Automatic; |

Product Application

T-600GY high efficiency full automatic edge banding machine has additional functions such as corner trim and pre milling, it's good for wood, MDF, plywood edge banding work. The edge banding material can be PVC, Acrylic and ABS. Wood belt is also optional! Minimum working thickness of boards is 9mm!

It's idea selection with full functions automatic edge banding machine.

T-600GY Edge Banding Machine Automatic Main Features

1. Taiwan Delta frequency controller, insured the duration and precision of our wood edge banding machine.

2. PLC use LG brand, air cylinder use SMC from Japan, HIWIN liner track, Honeywell limitation switch, Taiwan CPG conveyor motor, all key parts we choose market tested best brands to try to guarantee our machine performance and let our customers enjoy to use our machines.

3. Independent lifting up and down system, simple and convenient.

4. Precise encoder control, high speed.

5. Special polishing structure, motor angle can be universal adjusted, make the PVC/Acrylic/ABS band polishing and buffing to the best.

6. Glue spray clean system is optional, it's good to remove the glue and dirty on MDF/Wood during edge banding process.

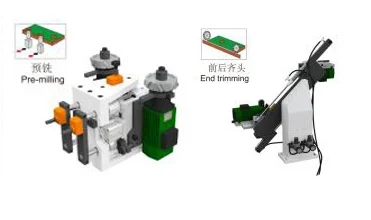

Funtions: Pre-milling / Gluing / End Trim/ Rough Trim / Fine Trim / Corner Trim/ Scraping / Buffing

Pre-milling and End Trim

Buffing and Gluing

The buffing device adopts cotton material polishing wheel to sand the finished edge band more smoothly.

Gluing facilities use special structure to evenly spread the glue on both banding panel and band, ensure a more solid adhesion force.

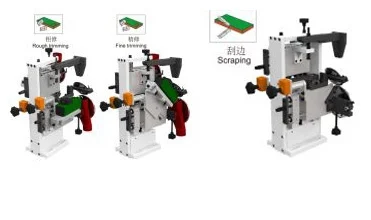

Fine Trim / Rough Trim and Scrapping

Fine and rough trim facilities are used to remove the extra material on band, it adopts mould automatically track and high frequency high speed motor, ensure the plain and smooth of work piece top and bottom parts.

Scraping units used to remove the texture which might happened during trim processing, guarantee the band to be smooth and plain.

Grooving

Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc.

To get response right now, plz email or call /WeChat /Whatsapp Mr. Daniel at +86-18665405636

To follow us on Facebook, plz visit: https://www.facebook.com/ileabon

To watch our machines operation video on youtube, plz visit: https://www.youtube.com/user/welfecn/videos

Six Rows Drilling/ Boring Machine MZ76216A

91.8% Response Rate

Sliding Table Panel Saw MJQ6132PB

91.8% Response Rate

Automatica Edge Banding Machine T352

91.8% Response Rate

-

LB802 woodworking mini automatic PVC edge banding machine MDF panel furniture wood edge banding machine price

-

SINO F200MAX hot sale high quality automatic edge banding machine edge banding machine diy through feed edge banding machine

-

Speed adjustable portable small round plate edge banding machine edge press machine

-

45 degree high map automatic edge banding machine

-

MY07C Automatic Woodworking Edge Banding bander Machinery for 3mm edge banding wood

-

Straight Automatic Edge Banding Machine with Pre-milling for Furniture

-

Mould door skin hot press machine for different size wood door

-

automatic pvc mdf edge banding machine woodworking for wood

-

MY06D Furniture portable pvc melamine automatic wood manual edge banding machine

-

small manual edge banding machine

Other Products

-

$2000.00 / set

$2000.00 / set -

$11580.00 / set

$11580.00 / set