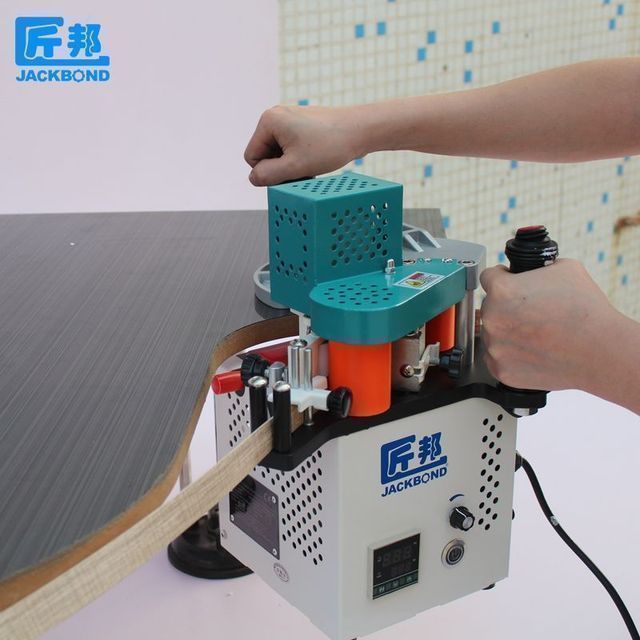

Speed adjustable portable small round plate edge banding machine edge press machine

-

Supplier: Foshan Jackbond Electromechanical Manufacturing Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Queenie Yang -

Price: $357.00 /set -

Min. Order: 1 set

| Power (watts): | 765W | Card: | jack bond |

| Panel feed speed (m/min): | 5 m/min | Warranty: | 1 year |

| type: | Banding Machine | Voltage: | 220V 110V, 220V 110V |

| pack: | 1 set/box | Custom processing: | customizable |

| Video shipment inspection: | if | Core component warranty: | 1 year |

| net weight: | 9.5 kg | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Package preview: | usage: | MDF production | |

| Power (kW): | 765 | Health status: | new |

| Applicable industries: | Machinery repair shop, manufacturing plant, retail, woodworking machinery | weight: | 9.5 kg |

| place of origin; place of origin: | Guangdong, China | brand: | jack bond |

| Core components: | motor | gross weight: | 14 kg |

| Main selling points: | easy to operate | Weight (kg): | 14 kg |

| Packaging Details: | Jackbond products are packaged in cartons and shockproof foam, and provide customized wooden frame packaging services for special requirements. | Dimensions (L*W*H): | 375x300x420mm |

| Function: | glued | size: | 380*330*380mm |

| Forms of work: | manual |

JBD90 is a portable edge banding machine using hot melt adhesive. It uses PVC, ABS, Melamine, Wood straps pre-cut to appropriate length to tie straight, curved and beveled edges. And the speed can be adjusted, and the user can operate freely. For small curved or straight panels, the machine can be fixed on the console for easy edge banding. For large-area curved or straight plates, users can hang the machine above the plate for strapping operations. This machine is compact in structure, light and flexible, easy to operate and perfect in edge banding effect. Ideal for manufacturing and decoration projects.

| brand | jack bond |

| product name | JBT90 |

| net weight |

9.5 kg |

| size | 340×310×350MM |

| total power |

765 watts |

| Voltage | 220V/110V,50~60HZ |

| Edge thickness | 0.3-3MM |

| edge width | 10-45MM |

| Processing rate | 0.5-5m/min |

| temperature | 120-180℃ |

| form of glue | single standard glue |

| gross weight | 14 kg |

| package volume | 38×30×42CM |

The portable edge banding machine can be placed on a small gantry for desktop wood edge banding. This operation is suitable for small wood edge banding.

Below is a rendering of the veneered planks. Jackbond edge banding machine is suitable for PVC edge banding, ABS edge banding, veneer edge banding, NDF board, ecological board, particle board, wooden door, honeycomb board and other wooden boards.

The panels can be held in place while the hand-held edge bander is in progress. It is also possible to fix the machine on a conveyor belt or a table with stand for small size boards. The edge banding process is the same as normal size goods.

Please click on the tool picture below to enter our store to purchase woodworking tools.

company information

born for you

Jiebang Motor Manufacturing Co., Ltd. was established in 2009, focusing on the production of portable edge banding machines, filleting machines, small edge banding machines, trimming machines and other small woodworking machinery. We manufacture and supply what you need, what you look for and what you like.

less is more

Jackbond only focuses on three things: developing new products, producing high-quality products and building a good reputation. Everything we do is to serve you better.

Quality First

Jackbond pays great attention to quality control. Jackbond has strict three 100% QC standards: materials are 100% inspected before assembly, final/finished products are 100% inspected before packing, and goods are inspected 100% again before shipment. 100% effort is only for your 100% approval.

Our advantage

1. Small MOQ for OEM customized service:

We provide professional OEM services, such as LOGO printing, customized packaging, customized user manuals, etc., to help each customer start small and gradually build themselves and your brand.

2. Five-star after-sales service:

We not only focus on selling goods, but also pay great attention to after-sales, including satisfaction surveys, product usage guides, technical support, return/repair defect items, etc.

Your ♦♦♦♦ 5-star review is our highest goal.

3. High-quality components:

All electronic components have passed the EU certification, and the core electrical components are all Schneider high-quality components.

FAQ:

Q1: How to proceed an order for JBT90?

- First, please send us an inquiry and let us know your requirements (important);

- Second, we will send you a complete quotation including shipping;

- 3. Confirm the order and make payment;

- Four, we will arrange production or shipment after receiving payment.

Q2: What is your payment terms?

We accept the following payment terms:

- Alibaba trade assurance, including Visa credit card, Mastercard, TT bank transfer, e-checking;

- PayPal, Alipay;

- Western Union, MoneyGram, etc.

Q3: How long is the delivery time? What is your fast delivery time?

According to the machine, 10-15 days after payment confirmed, some machines are in stock. For non-standard machines and customized machines, it may take 15 to 30 days according to the specific requirements of customers.

Dear customer, if this product meets your purchase needs, please contact Hana. Hana promises to reply you within 8 hours.

-

LB802 woodworking mini automatic PVC edge banding machine MDF panel furniture wood edge banding machine price

-

SINO F200MAX hot sale high quality automatic edge banding machine edge banding machine diy through feed edge banding machine

-

45 degree high map automatic edge banding machine

-

MY07C Automatic Woodworking Edge Banding bander Machinery for 3mm edge banding wood

-

Straight Automatic Edge Banding Machine with Pre-milling for Furniture

-

Mould door skin hot press machine for different size wood door

-

automatic pvc mdf edge banding machine woodworking for wood

-

MY06D Furniture portable pvc melamine automatic wood manual edge banding machine

-

small manual edge banding machine

-

High quality durable melamine compound preheater machine