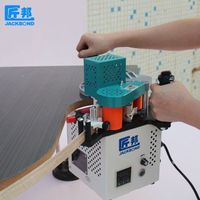

SINO F200MAX hot sale high quality automatic edge banding machine edge banding machine diy through feed edge banding machine

-

Supplier: Sichuan Vanwood Technology Co., Ltd. -

Region: Sichuan, China -

Contact: Ms Yina Zhang -

Price: $2100.00 / 1 - 39 sets

$1000.00 / >=40 sets -

Min. Order: 1 set

Product details

| Core components: | Bearings, motors, pumps, gears, PLCs, gearboxes, pressure vessels, engines | Voltage: | 220V/380V |

| product name: | edge banding machine diy | Packaging Details: | wood packaging |

| Applicable industries: | factory, carpentry | type: | Banding Machine |

| Core component warranty: | 1 year | Health status: | new |

| Dimensions (L*W*H): | 2140*500*1150MM | Name: | Through feed edge bander |

| Function: | glued | Supply capacity: | 300 sets per month |

| port: | Qingdao | usage: | MDF production |

| Weight (kg): | 240 kg | Video shipment inspection: | if |

| Panel feed speed (m/min): | 14 m/min | brand: | Sinosteel |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Origin: | China |

| Power (kW): | 3.55 | Main selling points: | easy to operate |

| Model: | edge banding machine diy | Warranty: | 1 year |

The appearance and packaging of the product will be continuously upgraded, and the shipping fee is subject to the actual quotation of the salesperson.

Gluing-trimming-finishing-scraping-polishing-vacuuming

1.The structure has been upgraded.

2. The edge trimming and scraping of the old F200 are placed on the same spindle, which is prone to the situation that the trimming or scraping does not work. The upgraded version of F200 trimming and scraping is completed independently by two motors, and the work is more stable.

3. Using arc edge trimming knife, the edge sealing effect is better.

Voltage | 380v | heating | 800w (5-10 minutes) | Edge type | straight line |

strength | 5 kW | Edge speed | 0-13m/min | Strip width | 10-60mm |

air pressure | 0.4-0.6mpa | send board | 180w(0-4m/min) | Strip thickness | 1-3mm |

Machine size | 2140*500*1150mm | prune | 800w*2 24000rpm | Sheet thickness | 10-50mm |

net weight | 320 kg | polishing | 200w*2 5500rpm | paper width | >80mm |

Package Size | 2270*720*1380mm |

The upgraded version of F200 adopts arc edge trimming knife, and the circular edge banding effect is better

Strengthen the 100*50 wide beam to ensure the parallelism of the plate drive, and double rows of inclined wheels.

control Panel

Profiled glue pot

Edge flakes are easier

Digital display is more convenient and accurate.

Multi-roller pressure wheel, plate transmission is more stable

About our comments

For more information please contact us

About our company

About SINO STAHL Who is SINO STAHL?

We focus on Chinese woodworking machinery business for more than 30 years. What are our advantages? We always understand customer needs, continue to serve more than 10,000 customers at home and abroad, and create one-stop services for customers. We have German technicians and customers, from their experience and technical skills, the quality of the machines we make is better than others. We have experience in all furniture crafts from panel furniture, solid wood furniture, paint craft, packaging craft, etc.

1. Our payment method?L/C and T/T or other ways.2. Delivery time?30 days after down payment. We have our own forwarder, we have long-term cooperation with each other, and we have a close relationship with each other, so there is no problem with shipment.3. Our warranty?(1) In the case of normal operation of one shift per day, one year warranty from the date of delivery of the machine. (2) We are responsible for repairing damaged parts under abnormal conditions during the warranty period, and the return express transportation costs for damaged/repaired parts during the warranty period are all borne by the buyer. Wear parts not included. (3) 24 hours technical support by email or telephone (4) User-friendly English machine use and maintenance manual4. Our service?(1) One-stop service to meet the needs of customers from individuals to international companies. (2) Accept OEM service. (3) Independent trading office: with 30 experienced sales staff, providing a full range of services. (4) After-sales service: experienced and knowledgeable technical support team, providing engineers overseas service.

Products are constantly being upgraded, subject to actual delivery. Buyers are not allowed to return or exchange goods on the grounds that the color appearance does not match the picture.

VIEW MORE

You may like

-

LB802 woodworking mini automatic PVC edge banding machine MDF panel furniture wood edge banding machine price

-

Speed adjustable portable small round plate edge banding machine edge press machine

-

45 degree high map automatic edge banding machine

-

MY07C Automatic Woodworking Edge Banding bander Machinery for 3mm edge banding wood

-

Straight Automatic Edge Banding Machine with Pre-milling for Furniture

-

Mould door skin hot press machine for different size wood door

-

automatic pvc mdf edge banding machine woodworking for wood

-

MY06D Furniture portable pvc melamine automatic wood manual edge banding machine

-

small manual edge banding machine

-

High quality durable melamine compound preheater machine

Related Search

large egg incubator high quality automatic

high quality automatic poultry plucker

high quality vacuum aluminium coating machine

high quality charcoal powder extruding machine

high quality mosfet portable welding machine price

high quality bamboo toothpick processing machines

high quality garbage bag making machine

high quality plastic injection moulding machine

high quality diamond tool polishing machine granite

high quality sugar cube making machine