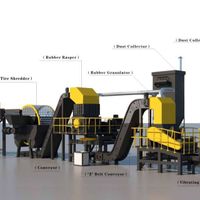

High-performance used tire recycled rubber production line rubber powder making machine tire recycling production line

-

Supplier: Qingdao Ouli Machine Co., Ltd. -

Region: Shandong, China -

Contact: Mr Roy Ren -

Price: $118000.00 / 1 - 4 sets

$110000.00 / 5 - 9 sets

$108000.00 / 10 - 14 sets

$105000.00 / >=15 sets -

Min. Order: 1 set

Product details

| application: | Waste tire recycling | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Video outbound inspection: | if | After-sales service provided: | Engineers can repair machinery overseas |

| Supply capacity: | 30 sets per month | Health status: | new |

| Name: | tire recycling machine | Main selling points: | High productivity |

| Core component warranty: | 1 year | Required seminars: | 300-1000 square meters |

| Place of origin: | Shandong Province, China | port: | Qingdao Port |

| capacity: | 200kg/hour-3000kg/hour | Mechanical test report: | if |

| Weight (kg): | 15000kg | weight: | 1 ton-22 tons |

| Packaging details: | Packaging: standard export wooden box | Warranty: | 1 |

| Suitable tires: | Nylon Tires, Steel Wire Tires, Truck Tires | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Finished product: | Rubber powder/fiber/steel | Marketing type: | New products for 2023 |

| Labor required: | 3-5 | brand: | Ouli |

| End product use: | Rubber floor tiles, reclaimed rubber manufacturing, rubber wheels | Package preview: | |

| Showroom location: | Canada, Turkey, United Kingdom, United States, France, Germany, Vietnam, Philippines, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Spain, Thailand, Morocco, Kenya, Argentina, Chile, Colombia, Algeria, Sri Lanka, Bangladesh, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan, Australia | Applicable industries: | Waste tire processing plant, rubber product manufacturing plant |

1 product description

Ouli's waste tire rubber powder equipment: consists of waste tire decomposition powder crushing and magnetic carrier screening units. Through the decomposition of waste tire facilities, the tires are processed into small pieces, and then the rubber pieces obtained are crushed by a crusher to obtain mixed rubber fans; then magnetic powder separation is performed to completely separate the steel powder and rubber powder. The fine material is filtered out through two sieve beds through the feeding device, and then passed through the magnetic roller and magnetic separation wire to prepare a purity of 10 mesh-40I

sHPowder (fineness optional). This processing technology has no air pollution, no waste water, and low operating costs.

This is the best equipmentTransformation and production of waste tire rubberpowder.

2 Workflow

3 other questions

VIEW MORE

You may like

-

Unvulcanized Steel Cord Scrap Rubber Steel Wire Separator

-

Tire recycling plant for waste recycling equipment

-

Semi-automatic waste tire recycling into rubber powder machine tire cutting machine

-

Reclaimed rubber production equipment

-

Used tire cutting machinery, tire recycling machinery for sale

-

Factory sale 1-2 tons waste tire rubber shredder recycling plant

-

Waste tire wire separator/tire wire remover/tire wire remover

-

Zero consumption tire doubling machine used tire doubling machine for sale

-

waste tire recycling machine used tire recycling shredder factory in pakistan

-

Electric old tire recycling machine shredder waste strip waste truck tire tread sidewall cutting machine

Other Products

-

$16000.00 - $16800.00 / set

$16000.00 - $16800.00 / set -

$3500.00 - $4200.00 / set

$3500.00 - $4200.00 / set -

$16800.00 - $36800.00 / set

$16800.00 - $36800.00 / set -

$22000.00 / set

$22000.00 / set -

$28000.00 - $28300.00 / set

$28000.00 - $28300.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$3500.00 / set

$3500.00 / set -

$1000.00 / set

$1000.00 / set

Related Search

rubber tile making machine

rubber slippers making machine

pvc rubber patch making machine

rubber chemical making machine

used tire recycling machine rubber crushing

used tire recycling machine to oil

used tire rubber crushing machine

rubber crusher used tire

used tire shredding line

recycled used tires and plastic