Best price welded wire mesh guardrail machine, reinforced fully automatic stainless steel welded wire mesh

-

Supplier: Guangdong Hwashi Technology Inc. -

Region: Guangdong, China -

Contact: Ms Kary Hou -

Price: $20000.00 /set -

Min. Order: 1 set

Product details

| Mechanical test report: | if | Weight (kg): | 1600kg |

| Marketing type: | Popular products | The output voltage: | 12V |

| Warranty: | 1 year | Package preview: | |

| type: | wire welding machine | Main selling points: | Well-known brand PLC |

| Video outbound inspection: | if | Rated working cycle: | 75% |

| Core components: | PLC, engine, gearbox, pressure vessel | Place of origin: | Guangdong, China |

| aspect: | custom made | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Health status: | new | usage: | Wire mesh welding |

| Showroom location: | not any | Input voltage: | 380 volts |

| weight: | 300-500kg | Packaging details: | Wood packaging, best price wire mesh welding machine |

| Service life: | 10 years | Input Current: | 400A |

| Certification: | CE and CCC | Professional welding cylinder: | 100*100mm |

| brand: | Fahrenheit | current: | 40000A |

| Applicable industries: | Building material stores, machine repair shops, manufacturing plants, construction projects | port: | Shenzhen Yantian Port |

| Effective welding length: | Within 3000 mm | Effective welding width: | 30~2200mm |

| Rated Capacity: | 150 kVA | Supply capacity: | 48 sets per month |

| Voltage: | 380V 50Hz | Core component warranty: | 1 year |

| Maximum welding current: | 34000A |

Product Description

Best price welded wire mesh guardrail machine, reinforced fully automatic stainless steel welded wire mesh

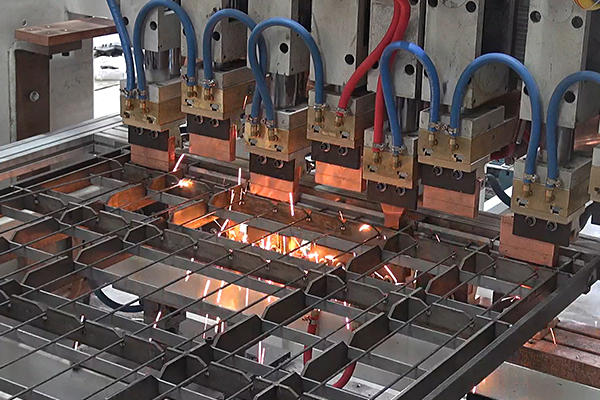

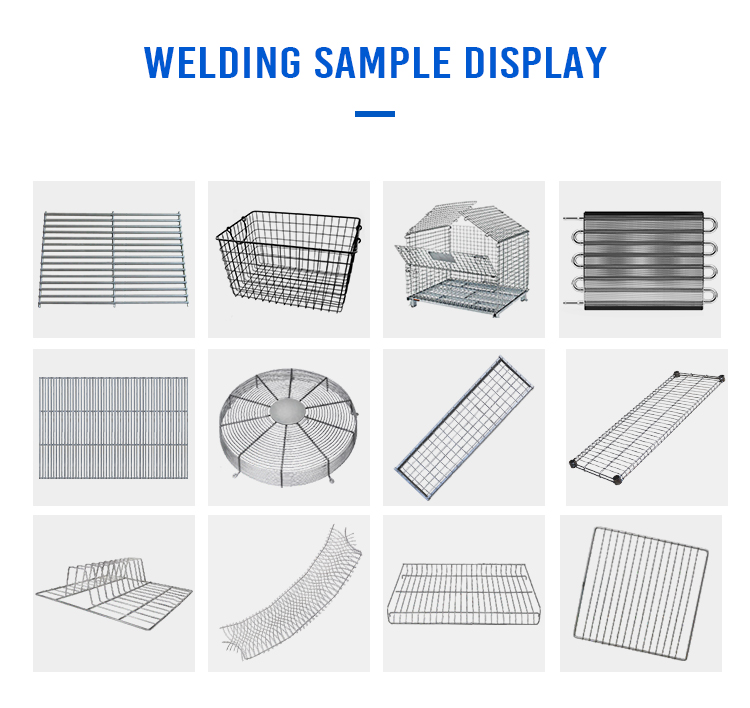

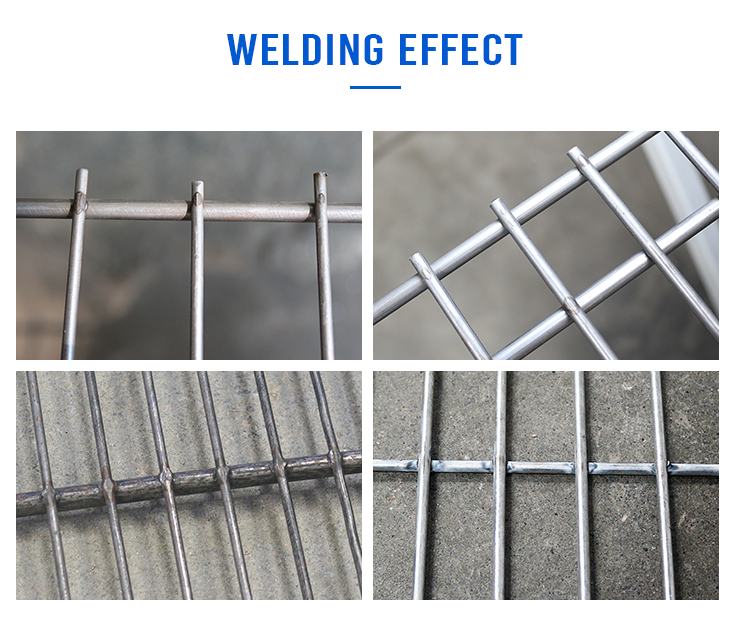

The refrigerator steel wire rack production line machine steel wire mesh spot welding machine is an H-type steel wire mesh multi-head automatic welding machine. It uses ten electrodes and is equipped with an automatic feeding system. The wire automatically falls onto the jig to achieve fully automatic loading. Feeding and welding are then performed automatically. Its one-way double-layer feeding device can automatically move forward and backward to complete welding, and the welding distance can be set arbitrarily, which is suitable for mass production of multi-point welding wire mesh. The welding method is one-way double-layer automatic stepping feeding, 10 welding heads. The effective welding width is 1200mm and the effective welding length is 1000mm. This machine consists of the main body, welding transformer, pneumatic driving device, upper and lower electrodes, automatic wire filling device, electrical control system, cooling system, PLC operation control system, etc.

Feature options

1. Power supply method: Type: three-phase medium frequency DC power supply system or two-phase AC power supply system Quantity: one power supply system or two power supply systems (double efficiency) 2. Feeder: double-layer automatic feeder (cyclic operation, servo motor Stepping position is accurate) or manual feeder 3. Unloading device: automatic unloading device or manual unloading device 4. Automatic bending device 5. Automatic straightening and cutting machine

We can customize the machine according to your requirements, please contact us if you need more detailed information about the above features.

Detailed description

1. Gantry welding machine is specially used for rapid production of wire mesh. Suitable for products with more Y filaments and less X filaments. 2. The welding power source is three-phase. The welding method is one-way double-layer automatic stepping feeding, 12 welding heads. (Can be adjusted according to your product) 3. The effective welding width is 1200mm and the effective welding length is 3000mm. (Can be adjusted according to your product)

Intelligent welding control system

Automatic welding is performed by inputting welding position coordinate data, welding current and other data.

Welding heads and fixtures

Processing design is carried out according to the drawings of each steel wire shelf product. (custom made)

Automatic line filling system

You can put the pre-cut straight wire into the hopper, and then the wire filling machine will automatically fill the wire into the clamp. It helps improve work efficiency and reduce labor.

Automatic double layer feeder

When one fixture is in the process of welding, the wire filling system will simultaneously load the welding wire onto another fixture. After welding is completed, the feeder will automatically change the fixture. So efficiency can be improved.

input power | 380V+10%/50HZ |

rated power | 100KVA*2 |

welding power source | 1.AC pulse power supply/2.MF DC power supply |

maximum. Secondary short circuit current e | 32kva |

Maximum wiring speed | 200 meters/second |

Effective welding length | 3000mm (customized) |

Effective welding width | 1000mm/1200mm1400mm (customized) |

Welding head | 6 sets/8 sets/10 sets (customized) |

Mobile control | Manual drive/automatic |

preset pressure | 0.5Mpa |

VIEW MORE

You may like

-

Mesh welding machine transformer accessories Mesh welding machine spare parts

-

ECU rework machine Heavy Wire Bonder/battery pack aluminum wire bonder

-

HWASHI steel wire shelf mesh manual spot welding machine

-

Best Price Hwashi Automatic Wire Mesh Welding Machine

-

YZ Detachable Steel Truss Floor Deck Welding Prefabricated Concrete Production Line

-

Precision Welding Mounter Equipment Wire Bonding Machine

-

Fully automatic EPS 3D sandwich wall panel welding machine

-

New Machines Automatic Welded Mesh Fence Panel Making Machine For Small Business

-

Manual machine for connecting battery pack wires

-

HWASHI Automatic Wire Mesh Welding Machine

Other Products

-

$800.00 / set

$800.00 / set -

$2000.00 / set

$2000.00 / set -

$6000.00 / set

$6000.00 / set -

$2000.00 / set

$2000.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10000.00 / set

$10000.00 / set

Related Search

best price metal laser marking machine

drinking water treatment machine with best price

best price french fries machine suppliers

stainless steel wire mesh

stainless steel flour dough mixer machine price

best price mini round hay baler

best price with high qualiti ku lnb suppliers

tig welding stainless steel welding wire

best price electric forklifts

4 frames electric reversible honey extractor for best price