Best Price Hwashi Automatic Wire Mesh Welding Machine

-

Supplier: Guangdong Hwashi Technology Inc. -

Region: Guangdong, China -

Contact: Ms Kary Hou -

Price: $2000.00 /set -

Min. Order: 1 set

| Maximum welding current: | 34000 A | Name: | Wire mesh welding machine |

| usage: | screen welding | aspect: | custom made |

| Shipping Details: | Ships within 30 days of payment | type: | Wire machine |

| Moving speed of loading rack: | 0.5 mm/s | The output voltage: | 12 volts |

| Effective welding length: | Within 3000mm | Rated Capacity: | 150 kVA |

| pper welding cylinder: | 100*100 mm | port: | Shenzhen Yantian Port |

| Service life: | 10 years | Supply capacity: | 48 sets per month |

| brand: | and stone | Effective welding width: | 30~2200mm |

| current: | 40000A | Certification: | CE and CCC |

| Nominal Duty Cycle: | 25% | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Input Current: | 400A | Packaging Details: | Wooden packaging, best price wire mesh welding machine |

| After-sales service provided: | Engineers available to service machinery overseas | Health status: | new |

| Origin: | Guangdong, China | weight: | 300-500kg |

| Voltage: | 380 Volts 50 Hz | Input voltage: | 380 volts |

Automatic wire mesh welding machine

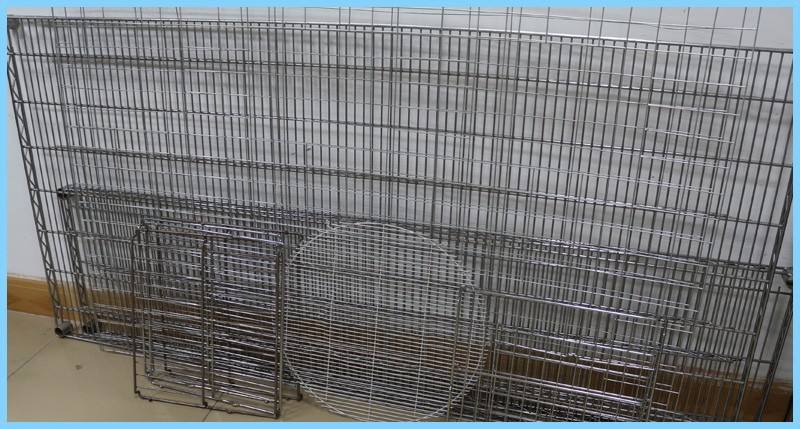

sample

workshop

welding

Some models of wire mesh welding machines

We can design and customize the machine according to your requirements, if you need more detailed function information,Please contact us.

1. This gantry welding machine is specially used for the rapid production of wire mesh. It is suitable for products with more Y-lines and less X-rays.

2. The welding power supply is three-phase. The welding method is one-way double-layer automatic stepping feeding, 12 welding heads. (Adjust according to your product)

3. The effective welding width is0~2200mmAnd the effective welding length is3000mm. (can be adjusted according to your own product)

Functional options:

1. Power supply:

Type: Three-phase medium frequency DC power supply system or two-phase AC power supply system

Quantity: one power supply system or two power supply systems (double effect)

2. Feeder: double-layer automatic feeder (circular work, servo motor precise stepping position) or manual feeder

3. Unloading device: automatic unloading device or manual unloading device

4. Automatic bending device

5. Automatic straightening and cutting machine

1. Main body: The longitudinal force-bearing body and high-quality thick steel plate are adopted to ensure the strength and stability of the main body.

2. Welding power supply: due to the long distance between welding wires, it is suitable for single-point welding. Therefore, this machine selects a suitable power 75/100/150/200KW special discharge transformer for resistance welding as the welding power source. To ensure the strength and stability of welding.

3. Welding control system: The secondary automatically recognizes the current output controlled by the microcomputer to ensure that the current of each welding spot is constant. At the same time, the control system has a voltage compensation function for automatic detection of voltage changes to ensure constant solder joint strength.

4. Pressurization mechanism: Multiple sets of pressurization mechanisms are used to drive the row welding electrodes to weld each welding wire separately.

![]()

It is suitable for batch welding of mesh, cage, fence and steel mesh. ETC.

1. It adopts SEMIKRON from West Germany or IXYS from the United States, which has high precision and long service life.

2. Using American Motorola integrated circuit and Japanese SIEMENS PLC, the response speed is fast and the performance is stable.

3. It adopts the Japanese Panasonic intelligent touch screen control system and is equipped with an automatic fault alarm system.

4. Adopt self-developed intelligent microcomputer welding control system control circuit with built-in voltage fluctuation compensation to ensure that voltage fluctuation is within ±15%.

5. Adopt Korean SANWO pneumatic components, stable performance.

6. All electronic components are made of Japanese Mitsubishi and Omron, with ideal service life and performance.

7. The transformer adopts Japanese high-purity silicon steel sheet, which has good magnetic and conductive properties.

8. High-precision full digital control system effectively solves the problem of cold welding or weld loosening caused by current shunting in projection welding.

9. Design the machine strictly according to CE safety standard. Reduce the accident rate.

-

Mesh welding machine transformer accessories Mesh welding machine spare parts

-

Best price welded wire mesh guardrail machine, reinforced fully automatic stainless steel welded wire mesh

-

ECU rework machine Heavy Wire Bonder/battery pack aluminum wire bonder

-

HWASHI steel wire shelf mesh manual spot welding machine

-

YZ Detachable Steel Truss Floor Deck Welding Prefabricated Concrete Production Line

-

Precision Welding Mounter Equipment Wire Bonding Machine

-

Fully automatic EPS 3D sandwich wall panel welding machine

-

New Machines Automatic Welded Mesh Fence Panel Making Machine For Small Business

-

Manual machine for connecting battery pack wires

-

HWASHI Automatic Wire Mesh Welding Machine

Other Products

-

$20000.00 / set

$20000.00 / set -

$800.00 / set

$800.00 / set -

$6000.00 / set

$6000.00 / set -

$2000.00 / set

$2000.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10500.00 / set

$10500.00 / set -

$10000.00 / set

$10000.00 / set