High Strength Compression Tear Testing Machine Universal Material Testing Machine Mechanical Tensile Testing Machine

-

Supplier: Dongguan Hongjin Test Instrument Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Hongjin Test Machine -

Price: $99.00 /set -

Min. Order: 1 set

Product details

| model: | Huajie | Test space: | 400mm diameter range |

| Package preview: | Extension unit: | mm, cm, inches, % | |

| Load cell accuracy: | 0.5% or less | Test speed: | 30~300mm/min adjustable |

| brand: | Hongjin | brand: | Hongjin |

| Capacity selection: | 1, 2, 5, 10, 20, 50, 100, 200, 500kg~10000kg | Warranty: | 1 year |

| Intensity resolution: | 1/50,000 | Strength unit: | kilogram, cow, pound, gram |

| Packaging details: | Fumigation-free export wooden box | Customization support: | OEM, ODM, OBM |

| Test maximum stroke: | Maximum 1200mm without clamp | Place of origin: | Guangdong, China |

| strength: | AC motors, electronics | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

Product Description

1. Main scope of Hongjin testing machineElectronic universal material testing machine, horizontal tensile testing machine, hydraulic universal testing machine, MFI, Charpy impact, Izod impact, hardness tester, torsion testing machine, metallographic series, oven, environmental test chamber (temperature and humidity chamber), UV Ozone, xenon aging test chamber, vibration testing machine, Hastelloy test chamber, waterproof test chamber, leak detection, optical detection series, etc. (We accept customization.)2. ProductsIntroduction: It adopts fully digital three-closed-loop control of power, displacement and speed, adopts AC motor and control drive system, and cooperates with precision worm gear reducer and precision screw drive to achieve the best results in transmission efficiency and signal-to-noise ratio. Function: This machine is used to test the physical properties such as elongation, compression, peeling, tearing bending, three-point bending, and shearing of metal and non-metallic materials. Meet standards: Can be customized to meet GB, ISO, JIS, ASTM, DIN requirements as well as testing and data processing standards provided by customers. Scope of application: This machine is often used for material analysis in industries such as auto parts, fasteners, aerospace, cables and wires, plastic rubber, and paper packaging.3. Characteristics of control and data processing systems1) The tester adopts advanced chip technology and professionally designed data acquisition and amplification system, which is highly integrated, reliable and convenient. The control software automatically exports tensile strength, yield strength, breaking strength, elastic modulus, and elongation data. The open formula editing function can automatically calculate the force, tensile displacement and deformation of any specified point. The standards in the control and data processing processes meet national requirements for testing of metallic materials and non-metallic materials. 2) Control method: constant speed, fixed displacement, constant load, constant load increase rate, constant tension, and constant tension increase rate. 3) Automatic clearing: After the test starts, the measurement system is automatically cleared. 4) Automatic gear shifting: Automatically changes the range when the load changes to ensure accurate data collection. 5) Automatic saving: Test data and test conditions are automatically stored to avoid data loss due to forgetting to save. 6) Batch testing: For test pieces with the same settings, batch testing can be performed after setting the test sequence. 7) Display mode: display data and curves during testing. 8) Curve display: After the test is completed, the curve can be re-viewed for analysis. Move the mouse over the curve to find data about each point. 9) Curve: Parameters: stress-strain, force-displacement, force-time, displacement-time results are displayed and can be printed. 10) Parameters: Force parameters (g, kg, N, lb) Stress parameters (kg/mm2, N/mm2, Mpa, lbf/in2) Displacement parameters (m, mm, in) 11) Test report: The test report is editable And print it according to the format required by the customer, and can output it as an Excel file. 12) Safety protection: The safety mechanism is triggered when the overload exceeds 2~10%. 13) The testing machine can automatically test and calculate the mechanical properties of the specimen. It is also possible to intervene manually in the analysis process. Automatically analyze test results and correct them according to relevant standards to improve data accuracy.

Specification

Test items | Strength and selective elongation |

intensity unit | Kilogram, Ox, Pound, Gram |

Capacity selection | 1, 2, 5, 10, 20, 50, 100, 200, 500 kg, 1000 kg, 2000 kg, 5000 kg, 10000 kg, 20000 kg |

Load cell accuracy | 0.5% or less |

Test maximum stroke | Maximum 1200mm without clamp |

Test speed | 0.1~1000mm/min adjustable |

stop mode | Upper and lower limit safety settings, emergency stop button, Programmed force and elongation settings and specimen breakpoint sensing |

Well equipped | A set of standard fixtures, A copy of the user manual and a product warranty card |

strength | AC servo motor |

standard | Computer connection equipment (1 signal cable, 1 decryption lock, 1 program CD) |

monitor | computer monitor |

expansion unit | mm, cm, inches, % |

Power resolution | 1/100,000 |

test space | 400mm diameter range |

Product display

VIEW MORE

You may like

-

2 in 1 Laptop Motherboard DDR4 DDR3 Memory Slot Memory LED Diagnostic Analyzer Test Card

-

Programmable Environmental Climate Chamber Humidity Temperature Test Chamber Climate Temperature Test Chamber Humidity Test Equipment Price

-

Faro Focus S350 3D Laser Scanner w/ Accessories, Case And Extra Batteries

-

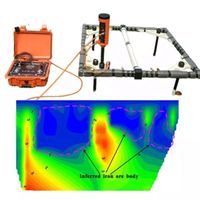

Geophysical Transient Electromagnetic Sounder TDEM Equipment with GPS

-

Digital clamp multimeter high-precision clamp meter to measure voltage and current clamp multimeter DT266

-

1AC-D non-contact electric measuring pen 90-1000V induction electric pen electroscope electrician electricity indicator

-

Home Delivery Promotion Thermo Scientific-Niton DXL-XRF Precious Metals Analyzer

-

Best Price X-ray Fluorescence Spectrometer Metal Element Testing Handheld XRF Explorer 5000 EXP5000 Analyzer

-

2022 best-selling transparent electric screwdriver test pen multi-functional induction test pen

-

Ground penetrating radar

Other Products

-

$500.00 / set

$500.00 / set -

$11000.00 - $12800.00 / set

$11000.00 - $12800.00 / set

Related Search

universal materials measuring machine

high strength motorcycle chains

high quality vacuum aluminium coating machine

high quality charcoal powder extruding machine

high output big cube ice machine

high strength welding wire suppliers

high strength t bolt with nut

high frequency industrial canvas welding machine suppliers

high pressure processing fruit vegetable machine

high strength bolts torsional shear