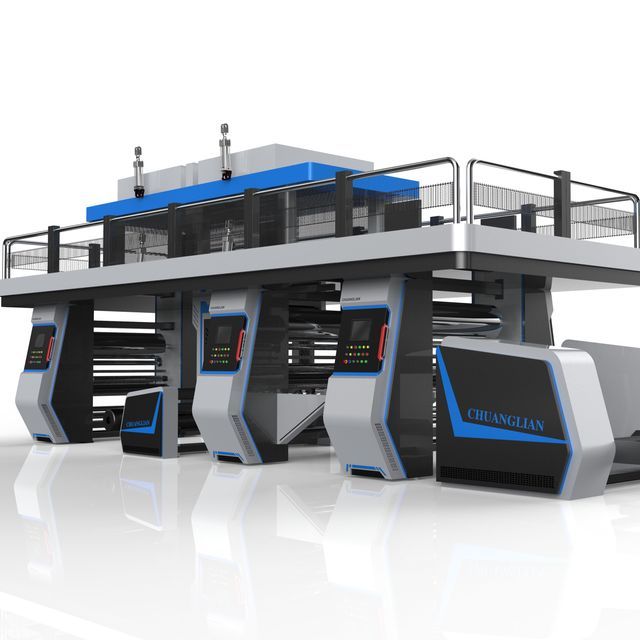

Fully automatic flexo printing machine printing machine

-

Supplier: Wuxi Chuanglian Packaging Machinery Manufacturing Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Darren Shi -

Price: $30000.00 /set -

Min. Order: 1 set

Product details

| Marketing Type: | 2019 Hot Products | Mechanical test report: | if |

| Dimensions (L*W*H): | 4200*2160*3150mm | usage: | Paper Printers, Label Printers, Card Printers |

| port: | Shanghai | Health status: | new |

| Packaging Details: | Wrapped with plastic film or wooden box | Voltage: | 380 volts |

| Core component warranty: | 1 year | Plate type: | Typography |

| After-sales service provided: | Online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support | Applicable industries: | Manufacturing plants, retail stores, print shops |

| type: | Flexographic printing machine | Certification: | CE certification |

| Warranty: | 1 year | brand: | Chuanglian |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Showroom location: | not any |

| Colors and Pages: | Polychromatic | Origin: | China |

| Video shipment inspection: | if | Core components: | Motors, pumps, gears |

| Local service location: | not any | Main selling points: | automatic |

| payment terms: | wire transfer | Automatic level: | automatic |

| Supply capacity: | 2 corrugating machines per month | weight: | 5000 kg |

Product Description

Specification

thing | value |

type | Flexographic printing machine |

Applicable industry | Manufacturing plants, retail stores, print shops |

After Warranty Service | Video technical support, online support, spare parts, on-site maintenance and repair services |

local service point | not any |

Showroom location | not any |

Health status | new |

plate type | Typography |

birthplace | China |

brand | Chuanglian |

usage | Paper Printers, Label Printers, Card Printers |

automatic level | automatic |

color and page | Polychromatic |

Voltage | 380 volts |

Dimensions (L*W*H) | 4200*2160*3150mm |

weight | 5000 kg |

certified | CE certification |

Warranty | 1 year |

Online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support | |

main selling point | automatic |

marketing type | 2019 Hot Products |

Mechanical inspection report | if |

Video shipment inspection | if |

Core component warranty | 1 year |

core components | Motors, Pumps, Gears |

features

The structure of the upper paper printing unit of the traditional model freezes due to the rising hot air in the drying light box.

The gravity is small, not affected by the diameter of the plate roller, and the high-speed operation is more stable.

The plate roller adopts pneumatic conical node clamping method, which greatly reduces labor intensity

When loading and unloading, the backlash of the hollow shaft of the traditional machine can also be eliminated, and the high speed is more stable

running.

The air duct, air inlet, air outlet and exhaust pipe of the drying system are all set on the top of the machine, with a width of

The machine is half of the traditional machine, and the ground is clean.

Open frame structure, convenient threading, one person can complete the whole machine threading,

Plus, the grounds are clean and convenient.

Double-sided adjustable pressure anilox roll, which can realize the adjustment of the pressure of the plate roll and

The anilox roller is pressed by one person. The patent is pending.

The distance between the paper and the ground is greater than 0.5m, thus eliminating the phenomenon of electrostatic adsorption of dust on the ground

Thoroughly in the process of skipping paper.

The closed scraper is used to avoid ink flying and ink splashing during high-speed operation;

And cut off the contact between the ink and the air during the printing process to ensure that the viscosity of the ink is not easy to change, and it is easier

to control chromatic aberration.

A version roller and a version roller pressure, position and register adjustment device.

The air intake system adopts PLT ceramic heater, which heats efficiently and has no open flame, making it safer to use

reliable.

The gravity is small, not affected by the diameter of the plate roller, and the high-speed operation is more stable.

The plate roller adopts pneumatic conical node clamping method, which greatly reduces labor intensity

When loading and unloading, the backlash of the hollow shaft of the traditional machine can also be eliminated, and the high speed is more stable

running.

The air duct, air inlet, air outlet and exhaust pipe of the drying system are all set on the top of the machine, with a width of

The machine is half of the traditional machine, and the ground is clean.

Open frame structure, convenient threading, one person can complete the whole machine threading,

Plus, the grounds are clean and convenient.

Double-sided adjustable pressure anilox roll, which can realize the adjustment of the pressure of the plate roll and

The anilox roller is pressed by one person. The patent is pending.

The distance between the paper and the ground is greater than 0.5m, thus eliminating the phenomenon of electrostatic adsorption of dust on the ground

Thoroughly in the process of skipping paper.

The closed scraper is used to avoid ink flying and ink splashing during high-speed operation;

And cut off the contact between the ink and the air during the printing process to ensure that the viscosity of the ink is not easy to change, and it is easier

to control chromatic aberration.

A version roller and a version roller pressure, position and register adjustment device.

The air intake system adopts PLT ceramic heater, which heats efficiently and has no open flame, making it safer to use

reliable.

VIEW MORE

You may like

-

Flexographic Printing Machine Corrugated New High Speed Ci Woven Shopping Bag Flexographic Printing Machine

-

YT-4600 flexographic printing machine flexographic printing machine 6 colors

-

Flexo Label Printing Machine, High Quality Flexo Printing Machine, 8 Color Flexo Printing Machine

-

Online Monochrome Logo Flexo Printing Machine

-

2 Colors Non Woven Film Bag Flexo Printing Machine Plastic Paper Flexo Sachet Printing Machine Machinery

-

2 3 4 5 6-color paper cup blank fan-shaped printing punching machine

-

Digital label printing machine ZBRY-480

-

With Dryer Logo Flexographic Printing Machine Automatic Paper Bag Printer 1-5 Colors Non Woven Plastic Bag Printing Machine Printing Machine

-

Single color mini flexo printing machine

-

Film bag water bag printing machine

Other Products

-

$800000.00 / set

$800000.00 / set

Related Search

fully-automatic blow moulding machine

fully automatic brick making machine

fully automatic terminal crimping machine

fully automatic dry cleaning machine in india

fully automatic shoe washing machine

fully automatic ultrasonic cleaning machine

washing machine fully automatic in washing machine

fully automatic steel chain machine

semi fully automatic blow molding machine

fulli automat wire coil machin suppliers