Hot selling gypsum powder/gesso/ plaster of paris equipment

-

Supplier: Linyi City Mengshan Tourism District Huabang Building Materials Co., Ltd. -

Region: Shandong, China -

Contact: Mr zhao David -

Price: $175600.00 /set -

Min. Order: 1 set

| Voltage: | 220V; | Warranty: | 1 Year; |

| Annual capacity: | 15000 to 500000 tons; | Power(W): | According to the annual capacity; |

| Heating method: | Hot oil and hot air; | Mesh: | 170 meshes; |

| Fuel for the heating: | Natural gas,coal,diesel,heavy oil,light oil etc; | Payment Terms: | L/C,T/T; |

| Packaging Detail: | Plaster of paris equipment:the packing will suitable for long distance shipment.; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| We are selling: | Plaster of paris equipment; | Application: | Produce gypsum powder; |

| Brand Name: | HUABANG; | Industry experience: | 16 years till 2015; |

| Raw material: | Gypsum ore; | Weight: | 120000kgs; |

| Dimension(L*W*H): | 45mx30m; | Automatic Grade: | Automatic; |

| Condition: | New; | Type: | Natural gypsum and FGD gypsum; |

| After-sales Service Provided: | Online support; | Port: | Qingdao port,China; |

| Features: | Customized product; | Place of Origin: | Shandong China (Mainland); |

| Checking: | SGS CIQ; | Supply Ability: | 20 Set/Sets per Year; |

Hot selling gypsum powder/gesso/ plaster of paris equipment

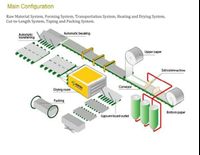

- Annual capacity of plaster of paris equipment:

15000 to 500000 tons

- Type:

Natural gypsum and FGD gypsum

- Degree of automation:

fully automatic and semi automatic

- Fuel for the boiler:

natural gas,coal,desel,heavy oil,light oil etc

- Final product specification:

Gypsum powder

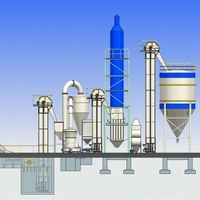

Raw materials crushing system_________________________________________________

- The crusher breaks the big sized gypsum ore into small ones with 25mm in diameter

- High efficiency grinding machine

- The equipment reliability and practicability significantly increased

- Make gypsum powder processing more stable, purity

- Simple structure;it is not easy to damage

- Space-saving;intensive equipments

- The low cost of the energy

- High quality,the content of the hemi-hydrate is ideal,the physical property is stable.

Finished product conveying and storage____________________________________

- Bucket elevator

- Finished product silo

- Silo wall vibrator

- Single way screw sluice gate

- Steel impeller feeder

- Packing machine

Dust collecting system____________________________________________________

- The output of the dust of the high-voltage electrostatic dust collector reaches to the local environment demands.

Heating system _____________________________________________________________

- Fuel:Natural gas,coal,diesel,heavy oil,light oil,etc

Electric control system_______________________________________________________

- Using the advanced DCS and also SIMENS PLC, separated equipment but concentrate control

- Improves the scheduling and decison efficiency

- Promotes the production management level greatly.

The application of final product gypsum powder:

- Used for produce gypsum board

- Plaster

Machining advantages of gypsum powder equipment:

- All the raw materials and finishing treatment are certified by our suppliers and must passreceiving inspection before they are released for production;

- Products are precisely machined with high assembling accuracy.

Above loading photos are for your reference:

1. | All the electrical parts will load in wooden case,and others will in nude packing or bulk etc. |

2. | And all the goods will load in 40HQ,if the boiler is over weight or oversize then will load in framework or bulk freighter. |

3. | All of the packaging will be suitable for long distance transportation. |

4. | If you have any requirements about the packing,we will do it according to that. |

Service idea:all the customer concern is supposed to be paid close attention, fulfil our trust, try our best to enter the acme of perfection.

- Factory area:40000sq.m

- Direct manufacturer with 16 years experience till 2015;

- Our company has its own R&D team,then we can continuously provide customers with newest technology;

- Has its own installation and debugging team;

- Service tenet:outstanding idea,excellent team, high quality service.

1.Guarantee:

3 years (except the easy worn parts such as bearings, electric buttons).

2.Installation and debugging:

2 to 4 months when the buyer prepare the installation and commission conditions.

3.Technology training:

Provide free training.

4.In order to guarantee the machine running, each year we will send engineer to check and development the technology with the buyer.

5.If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms.

We want to know_______________________________________________________

- Do you have gypsum ore?If have,pls give us its test report.

- How much annual capacity do you interested in?Our offer is based on an assumption that the final product of gypsum powder is 170 meshes in fineness.

- Which type of the fuel for heating?natural gal,coal,diesel,heavy oil or light oil?

- Method of the heating type?Hot air or hot oil?

- Pls tell us your land area.

- Degree of automation for gypsum powder production line?

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

Other Products

-

$201000.00 / set

$201000.00 / set -

$246000.00 / set

$246000.00 / set