2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Supplier: Henan Turui Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms hn turui -

Price: $15900.00 /set -

Min. Order: 1 set

Product details

| use: | Production of gypsum powder | place of origin; place of origin: | China |

| Mechanical test report: | if | color: | According to customer requirements |

| Core Components Warranty: | 1.5 years | Core components: | Engines, Bearings, Gearboxes, Motors |

| Dimensions (L*W*H): | customizable | Install: | under technical guidance |

| Supply capacity: | 50 sets per month according to your requirements | quality: | high level |

| Main selling point: | long lasting | weight: | 50000kg |

| Raw materials: | plaster | payment terms: | letter of credit, wire transfer |

| Packaging Details: | Standard export containers, bare metal, motors and small parts are packed in wooden boxes. | Certification: | ISO9001:2008 |

| port: | Qingdao, Tianjin, Shanghai or other port requirements | Advantage: | high efficiency |

| product name: | 2022 Factory Price Gypsum Powder Making Machine | Applicable industries: | Building Materials Store, Energy & Mining |

| type: | Fully automatic | Showroom location: | Philippines, Indonesia, Pakistan, Russia, Kenya, Algeria, South Africa |

| Video external inspection: | if | strength: | 320kW |

| Warranty: | 1.5 years | capacity: | 1-50TPH |

| Marketing Type: | New Products 2020 |

Product Description

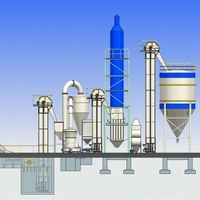

Gypsum powder making machine/gypsum powder production line

Gypsum powder production line is to produce gypsum powder that matches with gypsum board.The gypsum powder production line using natural gypsum as raw material is equipped with a variety of advanced technical equipment at home and abroad. The powder is classified by a classifier. The qualified powder that meets the required fineness is sent to the calciner, and the unqualified powder is returned to the mill for further processing. Gypsum powder, commonly known as plaster of paris, is stored in finished silos and used to make gypsum board stock.

application

Gypsum calcination process equipment production line - the latest Raymond mill, with bearing gear transmission, internal oil lubrication system, arc air duct and other intellectual property rights, has become one of the most advanced mills in the world.Widely used in cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic minerals, building materials, ceramics and other industries.It can process limestone, calcite, barite, dolomite, potassium feldspar, bentonite, medical stone, phosphate rock, manganese ore, iron ore, quartz, activated carbon, carbon black, ceramics, coal and other materials.

working principle

1>.RRaw materials crushed to a prescribed size are lifted into a hopper, and the raw materials are loaded from the hopper. Then, the materials are uniformly and continuously conveyed to the grinding chamber of the mill for powder processing through the vibrating feeder. After that, the ground material is brought into the classifier by the air of the blower for regrinding. The air flow system of the unit is tightly sealed and circulated under negative and positive pressure conditions.

2>. The gypsum pulverizer is rotated and driven by the central shaft through the reducer, and the upper end of the shaft is connected with the plum blossom frame on which the grinding equipment is fixed. The whole set of equipment rotates along the grinding ring together with the shaft, and the roller rotates under the drive of the component force. A set of shovels are installed at the lower end of the plum-blossom rack, and when they rotate together with the rollers, the shovels fall off. Press the filler into the gap between the roller and the ring to form a filler layer. The rotating drum rotates with the ring to grind the filler layer into powder.

3>.The rotational speed of the impeller can be adjusted according to the requirements of the fineness of the powder product.

4>.Gypsum grinding equipment plays an important role in ensuring the function of the grinding mill. When the high-speed rotating airflow is mixed with the ground material, it enters the cyclone collector, and the ground material is separated from the airflow.

technical parameter

Specification | ||||||

Annual production capacity | capacity per hour | Annual gypsum consumption | Calciner size | |||

20,000 tons | 2.7 tons | 24000 tons | 4.5 x 1.0 x 1.2 meters | |||

30,000 tons | 4.2 tons | 36000 tons | 4.5 x 1.2 x 1.4 meters | |||

50,000 tons | 6.9 tons | 60,000 tons | 4.5 x 1.4 x 1.6 meters | |||

60,000 tons | 8.3 tons | 72000 tons | 4.5 x 1.6 x 1.8 meters | |||

100,000 tons | 13.88 tons | 120,000 tons | 4.5 x 2.0 x 2.2 meters | |||

150,000 tons | 20.83 tons | 180,000 tons | 4.5 x 2.2 x 2.4 meters | |||

200,000 tons | 27.77 tons | 240,000 tons | 4.5 x 2.4 x 2.6 meters | |||

Gypsum product parameters:1. Fineness: ≥100 mesh; 2. Bending strength (directly related to raw materials): ≥1.8Mpa; Compressive strength: ≥3.0Mpa; 3. Main content: hemihydrate: ≥80% (adjustable) ; Gypsum <5% (adjustable); Soluble anhydrous <5% (adjustable). 4. Initial setting time: 3-8min (adjustable); Final setting time: 6~15min (adjustable) 5. Consistency: 65%~75% (adjustable)

Product advantages

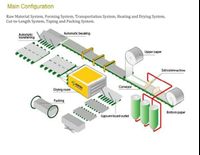

1. Feeding stabilization systemIt is used to realize stable replenishment, stable replenishment and heat supply of fluidized bed combustion boilers. The feeding stabilization system consists of a feeding stabilization bin and a conveying device (measuring screw or belt scale).2. Calcining systemThe gypsum material is uniformly calcined by the hot air boiling furnace calcination process.3. Cooling deviceThe plaster of paris should be cooled before entering the warehouse to prevent the gypsum from being deteriorated due to excessive temperature.4. Silo turning system:Materials from different periods have different qualities, so products made from them have different qualities. The silo turnover system can mix the old and new materials evenly, so that the product quality is consistent. In addition, the system prevents overheating degradation due to heat generated by powder build-up.5. Dust removal systemThe bag filter is adopted to ensure that the dust generated in the pre-drying, conveying, grinding, calcining and aging process is cleaned before being discharged to meet the requirements of the working environment.6. Distributed control systemApplication, centralized control of distributed equipment.

VIEW MORE

You may like

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

Automatic gypsum powder production line, gypsum powder factory

Other Products

-

$30000.00 - $40000.00 / set

$30000.00 - $40000.00 / set -

$11900.00 / set

$11900.00 / set -

$14999.00 / set

$14999.00 / set

Related Search

price of soap making machine

price cup plastic making machine

coconut oil machine fully automatic

gypsum board production line overseas installation

sale gypsum board production line

china gypsum board production line

automatic crumb powder production line suppliers

washing machine fully automatic in washing machine

button badge making machine price

full servo baby diaper making machine price