Gypsum board machine German gypsum board production line adopts Knauf technology

-

Supplier: Yurui (shandong) Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Cathy Dong -

Price: $300000.00 /piece -

Min. Order: 1 piece

Product details

| Video shipment inspection: | if | Core components: | Programmable Controllers |

| brand: | Yard | payment terms: | L/C, T/T |

| Package preview: | Origin: | Shandong China | |

| fuel: | Coal/gas/diesel/heavy oil, etc. | weight: | 100 kg |

| Applicable industries: | Hotels, building materials stores, machinery repair shops, food and beverage factories, home furnishing, food stores, construction projects | Mechanical test report: | if |

| experience: | 30 years experience | Dimensions (L*W*H): | 1200*3400*6700 |

| Core component warranty: | 1 year | Voltage: | 380w |

| Production capacity: | 12,000 tons~300,000 tons/year | Certification: | ISO9001:2000 |

| application: | building materials | Health status: | new |

| Main selling points: | long lasting | Showroom location: | Sri Lanka, Uzbekistan |

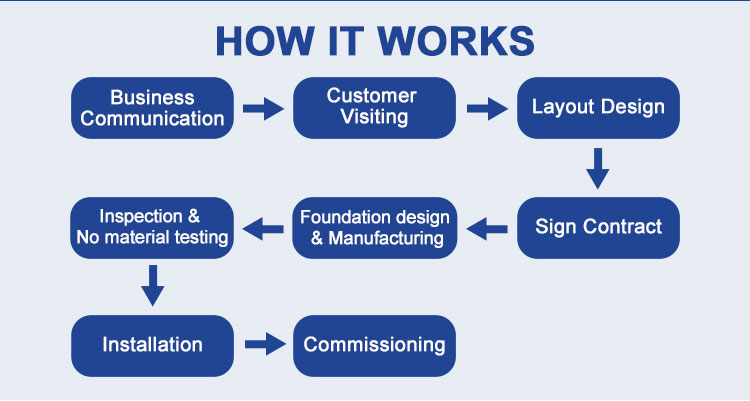

| Install: | Free installation/training/testing/commissioning | Packaging Details: | 1. 20FT/40FT standard sea and land package; 2. PLC controller is covered with foam film; 3. Spare parts and some parts are boxed; 4. All parts are fixed in the container with steel wires. |

| Warranty: | 1 year | Annual production capacity: | 9000~300,000 tons/year |

| Automatic level: | automatic | technology: | Fluidized fluidized furnace/rotary kiln |

| Supply capacity: | 1 set per month | strength: | 257.76 kW |

| feature: | Energy saving; environmental protection, saving engineering costs | Marketing Type: | New Products 2020 |

| After warranty service: | Video technical support | port: | Qingdao |

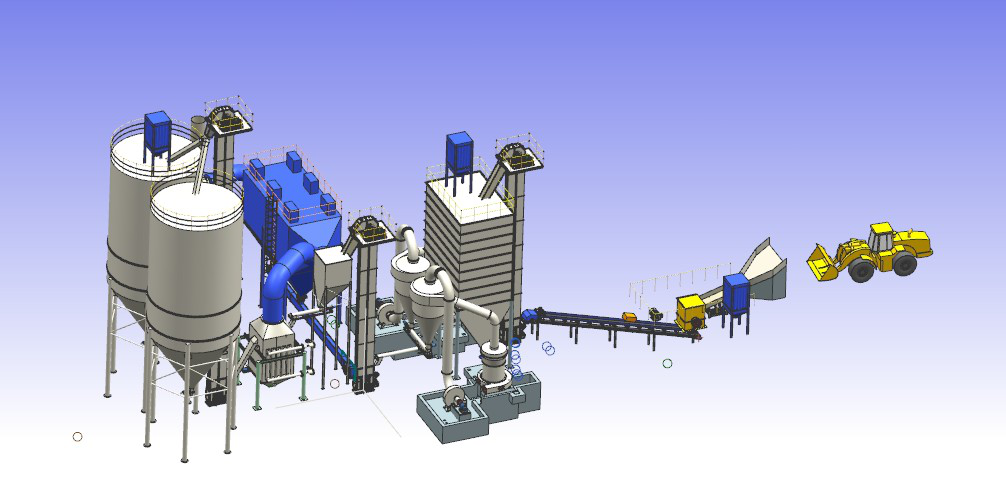

Device Details

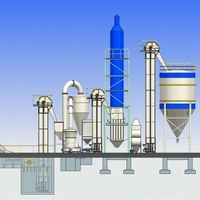

process flow

Raw material feeding

Crusher

Belt Conveyors and Elevators

Bag filter

raymond mill

Hot air boiling furnace

cooler

combustion chamber

Finished powder silo

gas tank

Electrical cabinet

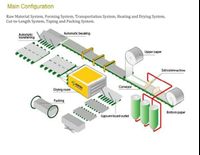

production line

advantage

technical features

1. Air dry

2.Material classification and crushing

3.no dust,There is no need to add dust removal equipment.

4.The whole process does not require cyclone separation

5.Ensure continuity of production

6. highcapacity,There is no need to add dust removal equipment.

7.Cost saving and environmental protection

vibrating feeder

1. The structure is compact and reasonable, and the vibration performance is stable.

2.Continuous and uniform feeding, long service life.

3.Impact resistance, large capacity, strong elasticity.

4.Low noise, low energy consumption and low maintenance cost.

grinding system

1.The electrical system adopts centralized control, and the milling workshop can be almost unattended.

2.The material is handled with a slight throwing motion to ensure less wear on the chute

3. aSuitable for conveying high temperature, easy to wear, corrosive materials, etc.

Calcination system

1. Reduce investment,power saving.

2.Short installation period and small footprint.

3.Environmental friendly.

Finished product packaging storage system

1. Waterproof, moisture-proof, easy to use,

2. 2 kinds of packaging machines can be selected3. Equipped with material level sensor equipment, you can keep track of the use of warehouse materials at any time

Dust removal system

1. The dust removal efficiency can reach above 99.9; the dust emission can be controlled below 30mg/Nm3 2. It can handle high-concentration dust below 100 g/Nm3

3. Advanced structural design, large filtration area per unit volume, and small equipment volume.

4. The quality of key components is reliable and the service life is long.

5.Stable performance, high degree of automation, simple maintenance and management.

Project display

hot product

VIEW MORE

You may like

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory

Related Search

gypsum board production line overseas installation

sale gypsum board production line

china gypsum board production line

decorative gypsum plaster board production line

mineral wool board production line suppliers

gypsum board paper production line

gypsum board line thermal oil technology

export gypsum production line

gypsum production line

production line machines