Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

Supplier: Henan Turui Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms hn turui -

Price: $14999.00 /set -

Min. Order: 1 set

Product details

| Mechanical test report: | if | Marketing Type: | New Products 2020 |

| strength: | 630kW | capacity: | 20-80 tons/hour |

| Core components: | Engines, Bearings, Gearboxes, Motors | After-sale service: | 1.5 year warranty |

| port: | Qingdao, Tianjin, Shanghai or other port requirements | Core Components Warranty: | 1.5 years |

| Packaging Details: | Standard export containers, bare metal, motors and small parts are packed in wooden boxes. | Factory tour: | warm welcome |

| Key words: | Gypsum powder manufacturing | Dimensions (L*W*H): | customizable |

| Showroom location: | Philippines, Pakistan, Mexico, Russia, Kenya, Algeria, South Africa, Kazakhstan, Uzbekistan | color: | customer request |

| place of origin; place of origin: | China | weight: | 45000 kg |

| Main selling point: | easy to operate | Install: | According to the engineer's guide |

| Advantage: | high working efficiency | Supply capacity: | 30 sets per month according to your requirements |

| quality: | high level | product name: | Gypsum powder manufacturing plant |

| Certificate: | ISO9001:2008/CE | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Video external inspection: | if | Warranty: | 1.5 years |

| Applicable industries: | Building Materials Store, Energy & Mining |

Product Description

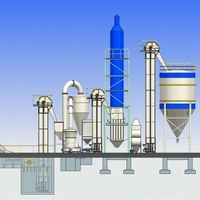

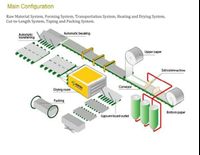

Gypsum powder production lineDevelopment, manufacture, installation and commissioning of gypsum powder production lines. The main processes include crushing system, grinding system, calcining system, energy supply system, packaging system, etc.

The annual capacity of the gypsum powder production line ranges from 30,000 tons to 600,000 tons. The gypsum powder line manufacturer has been building this machine for the past 20 years.The advantages of gypsum powder production line are low energy consumption, high degree of automation, small installation space and convenient operation.

Process flow

Raw material feed

Crusher

Belt Conveyors and Elevators

Baghouse

Raymond Mill

Hot air boiling furnace

cooler

combustion chamber

Finished powder silo

gas tank

Electrical cabinet

production line

Factory production uses multiple processes. first,The gypsum ore is crushed, transported, fed into the silo and put into storage.ThenThe pulverized gypsum ore is ground into powder with the required fineness by Raymond mill, and then the gypsum powder is transported to the calcination section for calcination through the metering feeding device. The calcined gypsum is modified by the pulverizer and cooled by the cooling device.at last,The finished gypsum is transported into storage.

technical parameter

Specification | ||||||

Annual production capacity | capacity per hour | Annual gypsum consumption | Calciner size | |||

20,000 tons | 2.7 tons | 24000 tons | 4.5 x 1.0 x 1.2 meters | |||

30,000 tons | 4.2 tons | 36000 tons | 4.5 x 1.2 x 1.4 meters | |||

50,000 tons | 6.9 tons | 60,000 tons | 4.5 x 1.4 x 1.6 meters | |||

60,000 tons | 8.3 tons | 72000 tons | 4.5 x 1.6 x 1.8 meters | |||

100,000 tons | 13.88 tons | 120,000 tons | 4.5 x 2.0 x 2.2 meters | |||

150,000 tons | 20.83 tons | 180,000 tons | 4.5 x 2.2 x 2.4 meters | |||

200,000 tons | 27.77 tons | 240,000 tons | 4.5 x 2.4 x 2.6 meters | |||

Gypsum product parameters:

1. Fineness: ≥100 mesh; 2. Bending strength (directly related to raw materials): ≥1.8Mpa; Compressive strength: ≥3.0Mpa; 3. Main content: hemihydrate: ≥80% (adjustable); Gypsum <5% (adjustable); Soluble anhydrous <5% (adjustable). 4. Initial setting time: 3-8min (adjustable); Final setting time: 6~15min (adjustable) 5. Consistency: 65%~75% (adjustable)

Product advantages

Technical Features

1. Air-drying 2. Material grading and crushing 3. No dust, no need to add dust removal equipment. 4. The whole process does not need cyclone separation 5. To ensure the continuity of production 6. High production capacity, no need to increase dust removal equipment. 7. Save money and protect the environment

vibrating feeder1. The structure is compact and reasonable, and the vibration performance is stable. 2. The feeding is continuous and uniform, and the service life is long. 3. Impact resistance, large capacity and strong elasticity. 4. Low noise, low energy consumption and low maintenance cost.

Grinding system1. The electrical system adopts centralized control, and the milling workshop can be almost unattended. 2. The material is treated by micro-throwing, which has little wear on the chute. 3. It is suitable for conveying materials such as high temperature, severe wear and corrosion.

Calcination system 1. Reduce investment and save electricity. 2. The installation period is short and the floor area is small. 3. Environmentally friendly.

Finished product packaging and storage systems1. Waterproof, moisture-proof, easy to use 2. Two kinds of packaging machines are optional 3. Equipped with material level sensor equipment, which can control the usage of warehouse materials at any time

Dust removal system

1. The dust removal efficiency can reach more than 99.9; the amount of dust can be controlled below 30mg/Nm3. 2. It can handle high-concentration dust below 100g/Nm3. 4. The key components are of reliable quality and long service life. 5. Stable performance, high degree of automation, simple maintenance and management.

Packaging and Shipping

Bale | ||

size | 11600 x 3500 x 2800mm | |

weight | 28 tons | |

Packaging Details | To accommodate size and weight, flat rack containers are used. | |

Bale | ||

size | 98000 x23000 x 19000mm | |

weight | 18 tons | |

Packaging Details | In order to facilitate loading and unloading, we chose an open-top container to load the hot blast stove. | |

VIEW MORE

You may like

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory

Other Products

-

$30000.00 - $40000.00 / set

$30000.00 - $40000.00 / set -

$11900.00 / set

$11900.00 / set -

$15900.00 / set

$15900.00 / set

Related Search

juic powder drying machin for sale suppliers

high and low beam projector lens

pressure switch air compressor compressor high and low pressure

large capacity paper shredder

high and low voltage protection

low cost dry mix mortar plant

high and low pressure film blowing machine

large black and white photography

large capacity e cigarette suppliers

good qualiti and low price suppliers