Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Supplier: Henan Turui Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms hn turui -

Price: $40000.00 / 1 - 2 sets

$30000.00 / >=3 sets -

Min. Order: 1 set

Product details

| strength: | According to model | Factory tour: | warm welcome |

| Supply capacity: | 10 sets per month according to your request | Mechanical test report: | if |

| Health status: | new | Core components: | Engines, motors, gears |

| Video shipment inspection: | if | Dimensions (L*W*H): | custom made |

| price: | Competitive (negotiable) | product name: | Calcined powder making machine gypsum powder production machinery factory |

| Specification: | can be customized | Main selling points: | long lasting |

| Voltage: | 220v/according to model | Certification: | ISO9001:2008, EU certification |

| Advantage: | High degree of automation and low cost | Core component warranty: | 1 year |

| factory: | 50,000 square meters closed workshop | Key words: | Gypsum Calcination, Gypsum Making Machine, |

| port: | Qingdao, Tianjin, Shanghai or other port requirements | Showroom location: | Philippines, Indonesia, Pakistan, Russia, South Africa, Kazakhstan, Uzbekistan |

| Marketing Type: | New Products 2020 | Applicable industries: | Building materials stores, machinery repair shops, construction, energy and mining |

| payment terms: | L/C, T/T | weight: | 7800 kg |

| Origin: | Henan, China | Install: | Engineer's Guide |

| Warranty: | 1 year | Packaging Details: | Standard export containers, bare hosts, motors and small parts are packed in wooden boxes. |

| Major equipment: | Gypsum powder, Portland cement, activated carbon | brand: | Turi |

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

Product Description

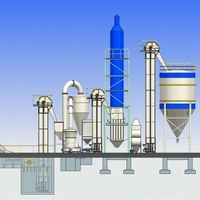

product display

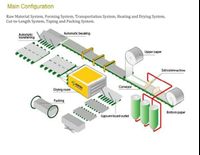

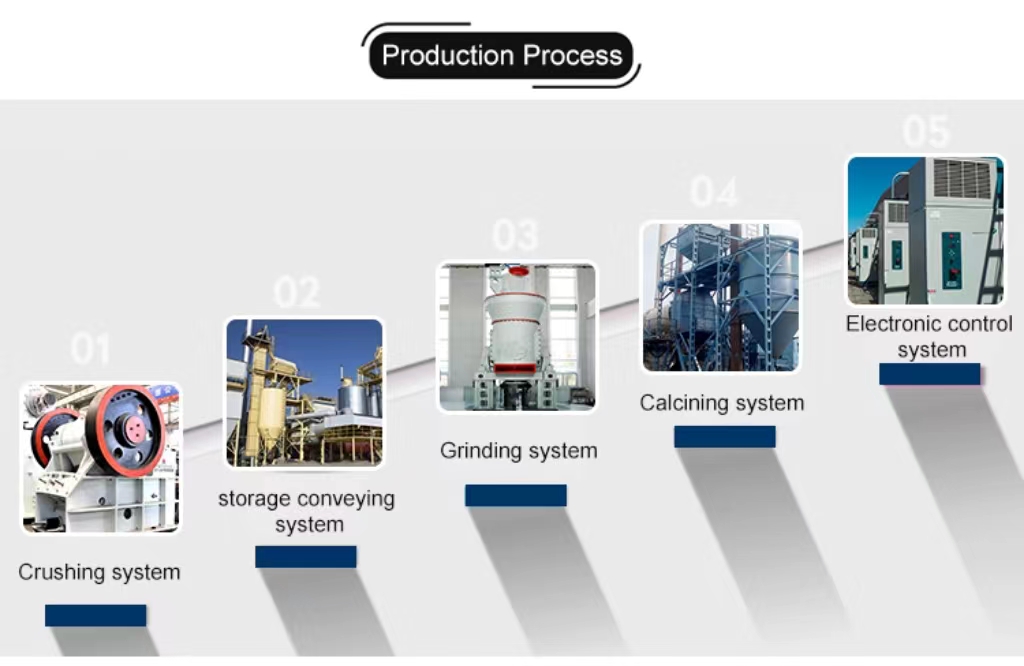

Product process

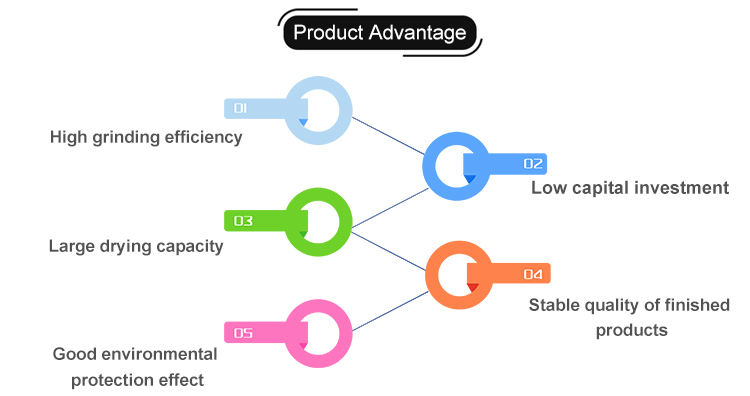

Product advantages

applicationProduct's

1.cement industry

Used in ceramic mold, cement retarder, food industry.

2.Medical industry

It has a certain antipyretic effect on febrile animals and can be used for the treatment of certain febrile diseases.

3.Secondbuilding materials

It can be processed into gypsum plaster, gypsum board, and gypsum mortar.

Gypsum production line for processingLimestone, dolomite, cement, bentonite, marble, talc, feldspar, fluorspar, phosphate, glass

1.cement industry

Used in ceramic mold, cement retarder, food industry.

2.Medical industry

It has a certain antipyretic effect on febrile animals and can be used for the treatment of certain febrile diseases.

3.Secondbuilding materials

It can be processed into gypsum plaster, gypsum board, and gypsum mortar.

work process

Our advantage

One-stop service

certificate display

Product parameters

capacity/ton | ton/hour | Consumption of raw gypsum stone T/year | heating method | Fluidized furnace size |

20,000 | 2.7 | 24,000 | heat transfer oil or steam | 4.5M×1.0M×1.2M |

30,000 | 4.2 | 36,000 | 4.5M×1.2M×1.4M | |

50,000 | 6.9 | 60,000 | 4.5M×1.4M×1.6M | |

60,000 | 8.3 | 72,000 | 4.5M×1.6M×1.8M | |

80,000 | November 11 | 96,000 | 4.5M×1.8M×2.0M | |

100,000 | 13.88 | 120,000 | 4.5M×2.0M×2.2M | |

150,000 | 20.83 | 180,000 | 4.5M×2.2M×2.4M | |

200,000 | 27.77 | 240,000 | 4.5M×2.4M×2.6M | |

300,000 | 41.66 | 360,000 | 4.5M×2.6M×2.8M |

VIEW MORE

You may like

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory

Other Products

-

$11900.00 / set

$11900.00 / set -

$14999.00 / set

$14999.00 / set -

$15900.00 / set

$15900.00 / set

Related Search

gypsum powder product plant

gypsum powder machine calciner

industrial gypsum powder calciner

calcination gypsum powder plant

gypsum powder calcination suppliers

gypsum powder calcination production

gypsum powder machine professional technology

automatic gypsum powder equipment with high quality

gypsum powder plant

gypsum board production line overseas installation