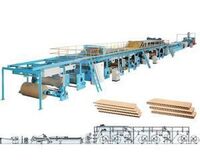

Fully automatic single-sided e-groove corrugated cardboard carton carton product making machine

-

Supplier: Cangzhou Kingsun Imp.& Exp. Co., Ltd. -

Region: Hebei, China -

Contact: Ms linda liu -

Price: $9800.00 /set -

Min. Order: 1 set

| Rod material: | alloy steel | type of packaging: | carton |

| Marketing Type: | other | Certification: | International Organization for Standardization |

| Name: | Corrugated Cardboard Carton Box Making Machine | weight: | 5 tons |

| brand: | KSPACK | Materials used for packaging: | Paper |

| Core component warranty: | 1 year | Voltage: | 380V or 220V |

| Approach: | thermoelectric | Layers: | 3.5.7 |

| Corrugated cardboard: | 2 floors, 3 floors, 5 floors according to customer requirements | Single face group: | Roll stand, single-sided machine, paper cutter, single tile machine |

| Type of machine: | single sided | State of health: | new |

| Main selling points: | easy to operate | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Showroom location: | Egypt, Germany | Applicable industries: | Machinery repair shops, food and beverage plants, farms, construction works |

| application: | Food, machinery and hardware | Types of: | Packaging line |

| After-sales service provided: | online support | Automatic level: | automatic |

| place of origin; place of origin: | Hebei china | Warranty: | 1 year |

| After warranty service: | Video Technical Support, Spare Parts | Key words: | Corrugated Box Making Machine |

| Dimensions (L*W*H): | $*2*1 | port: | Tianjin |

| Supply capacity: | 30 sets per month | Mechanical test report: | if |

| Core components: | Bearings, Motors, Engines | Driver type: | Mechanical |

| Effective width: | 1400-2200mm | Video shipment inspection: | if |

| Packaging Details: | wooden box and plastic film | Applies to: | Single face corrugated box making machine |

| Local service location: | Egypt, Germany |

Fully automatic single-sided e-groove corrugated cardboard carton carton product making machine

Two-layer corrugated paper machine production line is an ideal complete equipment for small and medium-sized carton factories. The corrugated paper production line consists of three machines. There are roll stands, single-sided 2-layer corrugating machines and paper cutters, known as the heart of the "corrugated cardboard production line", and the key equipment from single-layer paper to double-layer corrugated paper. The production line has the advantages of reasonable structural design, advanced production process, high efficiency, strong batch adjustability, convenient operation, etc., and has good working conditions.

Single facer unit includes: roll frame, 2-layer single facer, paper cutter, single corrugated paper machine

1. Mill roll stand : Single-sided automatic corrugated box machine

(aka corrugated box making machine)

|

Structural features: The symmetrical structure can install two bundles of paper tubes at the same time, which can realize non-stop paper replacement Electric o clamping, loosening, moving left and right Brake adjustment using the disc system. Two-stage automatic expansion with paper clip, chuck size 3 inches |

|

Technical Parameters 1. Active paper holder: mechanical electrical 2. Paper jam range: maximum 1400mm, minimum 100mm 3. Fixture diameter: up to 1400mm 4. The maximum load capacity on one side: 1500kgs 5. Power supply: 380V, 50Hz 6. Flip motor power: 1.5kw/set Clamping motor power: 0.75kw 4 sets 7. Manual brake model (optional pneumatic brake model) 8. Electrical appliance brand: DELIXI CHIT 9. Machine weight: 2.3T |

2. 2 ply single facer : single-sided automatic corrugated box machine

(aka corrugated box making machine)

|

feature 1. Cover the vacuum suction cup. 2. The corrugating roll is made of high-quality alloy steel 48CrMo, the surface is quenched by intermediate frequency, and chrome-plated. The hardness can reach HRC55~60, good wear resistance and long service life. 3. No gear transmission. 4. The rubber roller is lifted and lowered pneumatically. 5. Independent gluing device and electric gluing plate control gluing width. 6. Manual adjustment or electric adjustment display device. 7. It is lubricated with high temperature grease. 8. The surfaces of all jumping rollers and preheating rollers are ground and chrome-plated. 9. The pressure roller is quenched by intermediate frequency and chrome-plated. 10. The width is 1200mm~2000mm. 11. The preheating roller, pressure roller and corrugating roller all conform to the national standard of "Pressure Vessel". The working pressure is 1.1MPa. |

Technical Parameters

|

working width |

1200mm |

|

|

way to heat up |

Electric heating |

|

|

design speed |

80m/min |

|

|

economic speed |

45-60 m/min |

|

|

compressed air pressure |

0.4-0.9MPa |

|

|

flute type |

standard flute |

uve flute |

|

Standard |

Second |

|

|

For other types and models, we can produce according to customers' requirements. |

||

|

Corrugated roller diameter (mm) |

280 |

|

|

Wall thickness (mm) |

130 |

|

3. Paper cutter: single-sided automatic corrugated box machine

(aka corrugated box making machine)

The rotary paper cutter is an important unit of the single facer unit, which cuts the corrugated paper. Adopting the continuously variable transmission technology of advanced technology at home and abroad,

And manual control system, using mechanical system to cut paper, improve product efficiency and reduce work intensity

-

Metal can end making machine/can end production line

-

High-speed automatic carton cartoon box folding gluing machine corrugated carton carton gluing machine

-

Fully automatic high-speed vertical carton packaging food pizza bottle soap gloves plastic carton box packing machine

-

Carton Liner Bag in Box Line for Packaging Margarine Butter Semi-Liquids

-

Fully-automatic Bag in Box Filling Packaging Line

-

A full set of automatic filling and sealing pure drinking sachet water packaging line

-

Y-Pack buy kn94 n95 facial mask carton packaging machinery automatic cartoning machine cartoning machine

-

Best Selling Automatic Premade Bags Automatic Filling Sealing Packaging Machine

-

50-220L steel drum/barrel making machine

-

Fully Automatic Hot Selling Robot Carton Pallet Bag Palletizer, Shrink Bottle Palletizer

Other Products

-

-

$17800.00 - $24000.00 / set

$17800.00 - $24000.00 / set -

$17000.00 - $18500.00 / set

$17000.00 - $18500.00 / set -

$15000.00 - $17000.00 / set

$15000.00 - $17000.00 / set -

$6000.00 / set

$6000.00 / set -

$12000.00 / set

$12000.00 / set -

$100000.00 / set

$100000.00 / set -

$20000.00 / set

$20000.00 / set -

$30000.00 / set

$30000.00 / set -

$12000.00 / set

$12000.00 / set