High Precision CNC Stainless Steel Electric Shearing Machine Carpet Shearing Machine

-

Supplier: Anhui Yuanfang Machine Tool Manufacturing Co., Ltd. -

Region: Anhui, China -

Price: $2700.00 / 1 - 4 sets

$2500.00 / 5 - 9 sets

$2400.00 / >=10 sets -

Min. Order: 1 set

Product details

| CNC system: | E21S | Showroom location: | Kazakhstan |

| maximum. Cutting width (mm): | 1500 | Package preview: | |

| Shear angle: | 2°14' | Synchronize: | Yes |

| Warranty: | 1 year | After warranty service: | Video technical support, online support |

| Mechanical test report: | if | Video shipment inspection: | if |

| After-sales service provided: | Free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, online support, video technical support | Dimensions (L*W*H): | 2100*1050*1150 |

| Main selling points: | high accuracy | Automatic level: | fully automatic |

| Weight (kg): | 1150 kg | port: | Shanghai/Ningbo/Qingdao/Yiwu/Shenzhen/Guangzhou/Urumqi |

| brand: | reality | Core component warranty: | 1 year |

| Back gauge stroke(mm): | 20 - 500 mm | motor: | Siemens |

| Power (kW): | 5.5 kW | Health status: | new |

| place of origin; place of origin: | Anhui, China | year: | 2021 |

| Electrical components: | Schneider | Throat depth (mm): | 200 mm |

| Certification: | International Organization for Standardization | Cutting material: | Metal plate |

| Core components: | Bearings, motors, gears, pressure vessels, engines | Marketing Type: | New Products 2020 |

| Supply capacity: | 800 sets per month | Packaging Details: | Films and wooden cases that meet sea freight standards |

| Applicable industries: | Construction material stores, machinery repair shops, manufacturing plants, construction works, energy and mining, advertising agencies | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| power: | motor with reducer | maximum. Cutting thickness (mm): | 4 mm |

| Controller: | optional | Blade length (mm): | 1520mm |

| Function: | cutting sheet metal | Stop material: | Manual or CNC |

| Voltage: | 220V/380V/415V/440V | Local service location: | Kazakhstan |

| color: | optional |

Product Description

Electric Shearing Machine

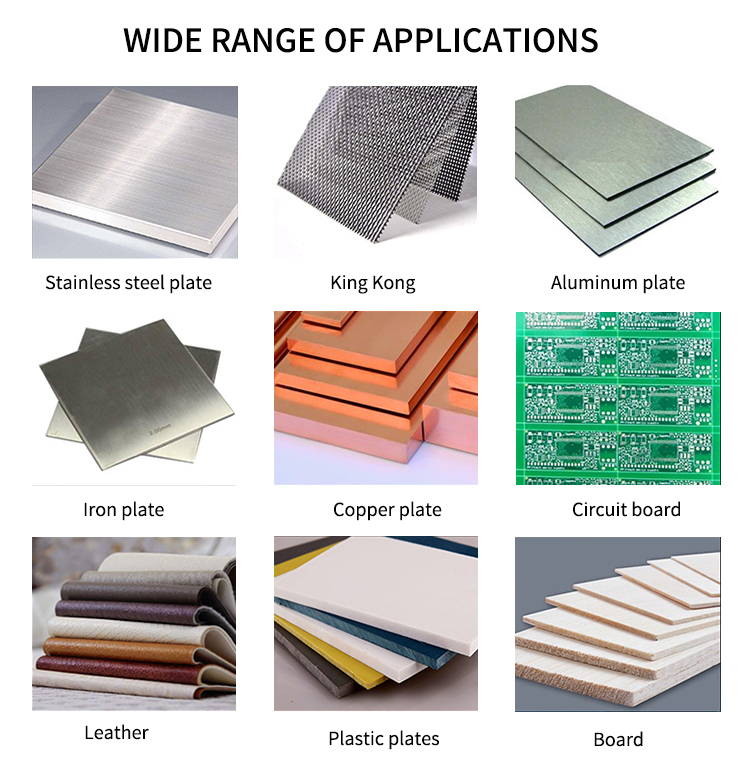

This machine adopts steel structure welding structure, simple structure, convenient operation, beautiful appearance, low energy consumption, can be equipped with gear reducer, electromagnet, foot switch can be remote controlled, suitable for metallurgy, light industry, machinery, hardware, etc. 0.1~ 6.0mm ordinary steel plate processing and shearing. Main features 1. The whole machine adopts integral welding structure, which ensures the high strength and good rigidity of the machine. 2. The machine has no clutch and flywheel. Shearing of sheet metal is driven directly by a magnetic brake motor. This reduces the idle time of the motor and saves energy. 3. The shearing blade is made of 6Cr2Si material to ensure good performance and long service life. 4. The machine has simple structure, convenient operation and low energy consumption.

detailed drawing

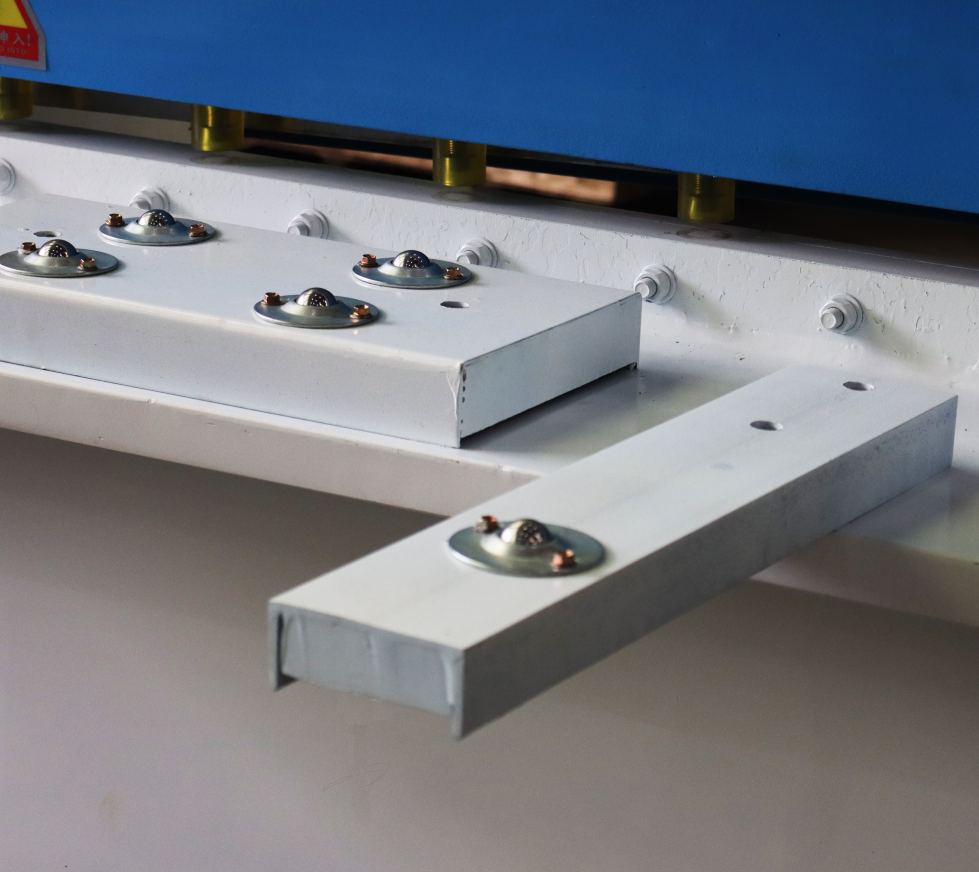

Front Support and Compression

■ball front support,Simple structure, powerful function, supporting sheet movement

■PPolyurethane compression, which can help hold the sheet in place for better cutting and nodamage to the surface of the sheet

Back gauge drive

■It is driven by a steep slope motor and a reducer with a limit switch to control the eccentric wheel, and then control the lifting mechanism of the tool holder, which is reliable and stable

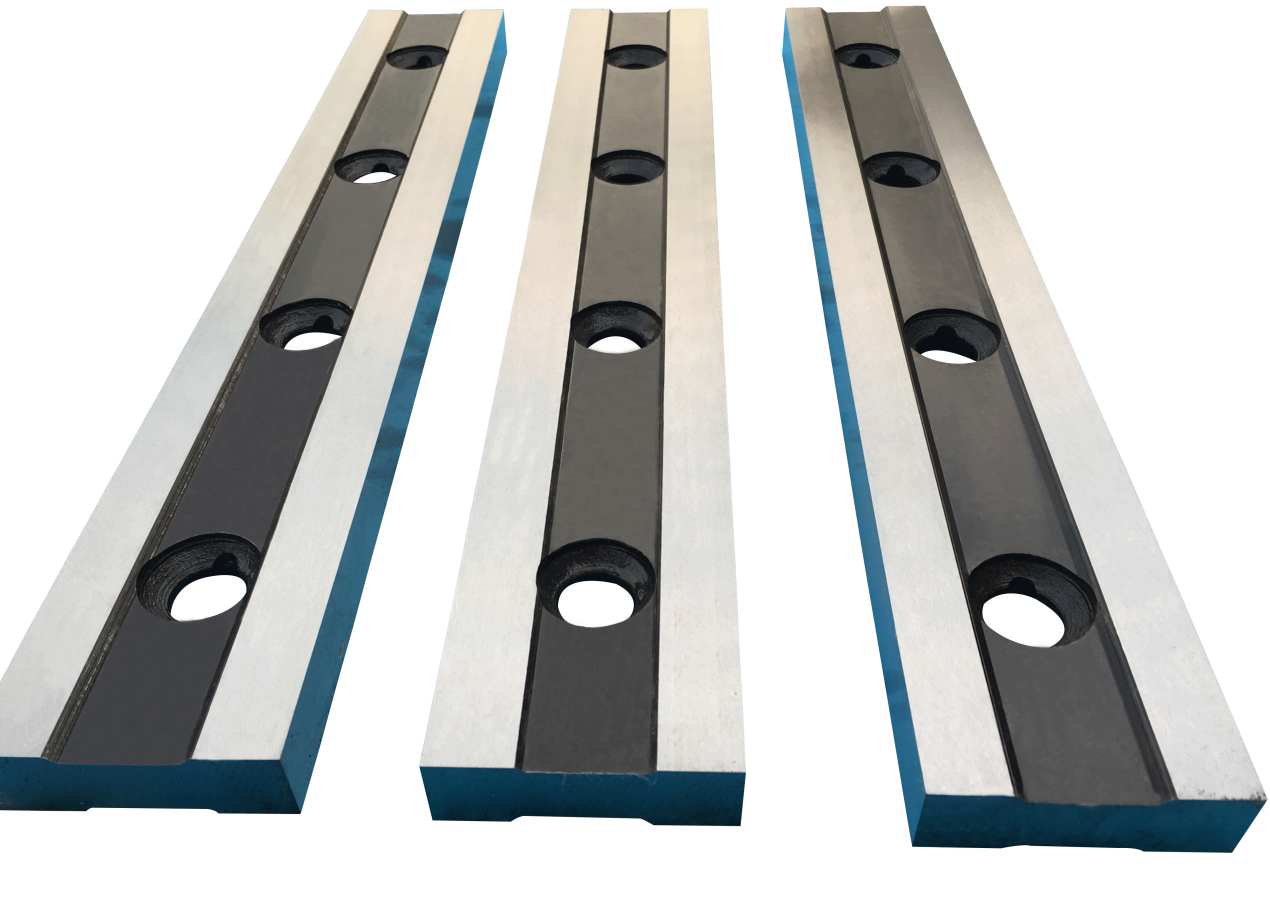

1. Material: 9CrSi, SKD-11, 6CrW2Si, Cr12MOV, H13.special tool steel

2. Hardness:HRC50-63For scissors,HRC45-63for thermal shear

3. High surface precision, no burr

4. Upper and lower blades with rectangular section, 4 blades are used

5. Strict quality management system

6. Accept small order.

7.OEM and ODM

Bade has high hardness, good wear resistance, reliable quality,

The variety is complete to meet your requirements.

2. Hardness:HRC50-63For scissors,HRC45-63for thermal shear

3. High surface precision, no burr

4. Upper and lower blades with rectangular section, 4 blades are used

5. Strict quality management system

6. Accept small order.

7.OEM and ODM

Bade has high hardness, good wear resistance, reliable quality,

The variety is complete to meet your requirements.

Product parameters

technical parameter

Model | to cut thickness (mm) | to cut width (mm) | Cutting angle (°) | Number of trips (times/minute) | Back gauge range(mm) | Motor power (kw) | aspect (mm) |

Q11G-3×1300 | 3 | 1300 | 2°14' | 33 | 500 | 4.5 | 1900×1050×1150 |

Q11G-3×1500 | 3 | 1500 | 2°14' | 33 | 500 | 4.5 | 2100×1050×1150 |

Q11G-3×1600 | 3 | 1600 | 2°14' | 33 | 500 | 4.5 | 2200×1050×1150 |

Q11G-3×2000 | 3 | 2000 | 2°14' | 33 | 500 | 5.5 | 2600×1050×1150 |

Q11G-3×2500 | 3 | 2500 | 2°14' | 30 | 500 | 5.5 | 3100×1050×1150 |

Q11G-4×1300 | 4 | 1300 | 2°14' | 30 | 500 | 5.5 | 1900×1050×1150 |

Q11G-4×1500 | 4 | 1500 | 2°14' | 30 | 500 | 5.5 | 2100×1050×1150 |

Q11G-4×1600 | 4 | 1600 | 2°14' | 30 | 500 | 5.5 | 2200×1050×1150 |

Q11G-4×2000 | 4 | 2000 | 2°14' | 28 | 500 | 7.5 | 2600×1050×1250 |

Q11G-4×2500 | 4 | 2500 | 2°14' | 28 | 500 | 7.5 | 3100×1050×1250 |

Q11G-2×2000 | 2 | 2000 | 2°14' | 33 | 500 | 4.5 | 2600×1050×1150 |

Q11G-2×2500 | 2 | 2500 | 2°14' | 30 | 500 | 4.5 | 3100×1050×1150 |

Q11G-6×1300 | 6 | 1300 | 2°14' | 28 | 500 | 5.5 | 1900×1050×1250 |

Q11G-6×1600 | 6 | 1600 | 2°14' | 28 | 500 | 7.5 | 2200×1050×1250 |

VIEW MORE

You may like

-

High quality hydraulic metal shearing machine factory price qc11y 16 3200

-

High work quality Q11 thin plate electric shearing machine, iron plate shearing machine, mechanical metal shearing machine

-

Mini CNC hydraulic shearing machine with simple operation Small stainless steel plate shearing machine price

-

AMUDA 10X2500 Pendulum Shearing Machine with MD11 Control System

-

cheapest mechanical shears

-

AH Shearing Machine for (Hydraulic, Economy Hydraulic, NC Swing Arm, Hydraulic Guillotine)

-

Stainless steel sheet iron aluminum small pedal shearing machine pedal shearing machine

-

QC11K / QC11Y 6x2500 mm Automatic Stainless Steel Sheet Metal CNC Hydraulic Guillotine Shearing Machine

-

Small manual steel shearing machine

-

1.5mm Manual/Manual Shearing Machine and Aluminum Cutting Machine

Related Search

high precision cnc stainless steel gears

cnc stainless steel machining part

stainless steel electric actuator valve

304 stainless steel csk head machine screw

stainless steel pipe polishing machine

stainless steel juice dispenser machine

stainless steel electric hand dryer

stainless steel sheet cutting machine

precision casting stainless steel

stainless steel electric thimble