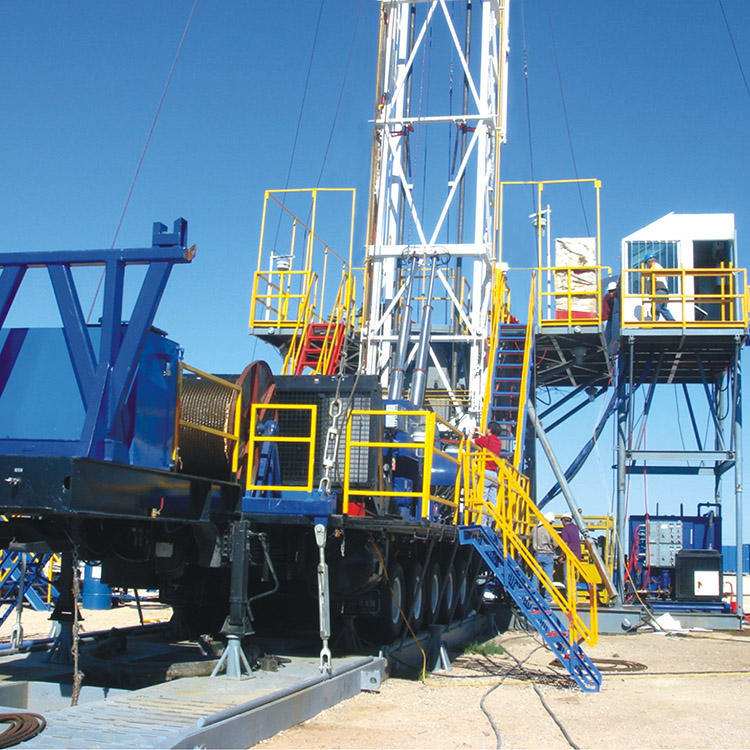

Easy to operate trailer mounted oil well drilling rig for oil well drilling

-

Supplier: RG PETRO-MACHINERY GROUP CO., LTD. -

Region: Henan, China -

Contact: Mr Sam Xue -

Price: $1000000.00 /set -

Min. Order: 1 set

Product details

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram | Video external inspection: | if |

| Supply capacity: | 4 sets per month | Certification: | API |

| place of origin; place of origin: | Henan, China | engine: | diesel engine |

| brand: | RG | Health status: | new |

| Mechanical test report: | if | color: | customer request |

| Function: | Drilling and milling | Local service location: | not any |

| custom made: | accept | Showroom location: | not any |

| type: | Rotary drilling rig | Marketing Type: | Hot Products of 2019 |

| Warranty: | 1 year | Power Type: | diesel engine |

| usage: | oil well | After-sales service provided: | Online support, video technical support, on-site installation and commissioning training, on-site maintenance and repair services |

| feature: | high efficiency | port: | Tianjin, Qingdao, Shanghai |

| Applicable industries: | Energy and Mining | model: | Trailer Rig |

| Packaging Details: | Products are packaged in wood or according to customer requirements | Core components: | Gearbox, Motor |

| Core Components Warranty: | 1 year |

Product Description

feature:

1. Trailer drilling rig drive can be divided into diesel engine drive, AC drive, DC drive and other forms, with reasonable power matching, high transmission efficiency, high reliability, compact structure, high degree of assembly, and small footprint. 2. It adopts a heavy-duty semi-trailer chassis for petroleum, with good mobility and off-road. 3. The main brake adopts band brake or hydraulic disc brake, and the auxiliary brake adopts pneumatic push disc brake and pneumatic clamp disc brake. 4. There are two mast groups with front opening, which are divided into forward tilt type and vertical type. 5. The rotary drive system can realize the forward rotation, reverse rotation, suspension and disconnection of the rotary table, and is equipped with a reverse torque release device to ensure the safe release of the rotary table drill string torque. 6. The drill floor adopts telescopic or spiral lifting structure, the floating platform on both sides can be turned over, and is equipped with a row of double bridges, which cannot be separated from the load during operation. Table height, size, layout can be customized. 7. Complete traction peripheral equipment such as solids control, well control, high pressure manifold, electronic control system, mud pump set, oil water tank, etc., as well as supporting conventional equipment. Can be arbitrarily matched, and can also be customized according to needs.

Specification

Model | ZJ10/600T | ZJ20/1350T | ZJ20/1580T | *ZJ30/1700T, ZJ30/1800T | ZJ40/2250T |

Maximum hook load (kN) | 600 | 1350 | 1580 (1600) | (*1700) 1800 | 2250 (*2500) |

Nominal drilling depth (114 mm) m | 500~1000 | 1200~2000 | 1200~2000 | 1600~3000 | 2500~4000 |

Winch power (kW) | 174 | 470 | 470 | 403×2 | 470×2 |

line | 6 | 8 | 8 | 10 | 10 |

Wire diameter (mm) | twenty two | 29 | 29 | 32 | 32 |

Mast Height (m) | 29 | 33, 35 | 35, 36 | 36, 38, 43 | 38, 47 |

Maximum hook speed (m/s) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Substructure height (m) | 3 | 4.5, 5 | 4.5, 5 | 6, 7, 7.5 | 6, 7, 7.5 |

RT hole diameter (mm) | 444.5 | 444.5, 520.7 | 444.5, 520.7 | 520.7, 698.5 | 698.5 |

main brake | Band Brakes and Disc Brakes | Band Brakes and Disc Brakes | Band Brakes and Disc Brakes | Band Brakes and Disc Brakes | Band Brakes and Disc Brakes |

auxiliary brake | 224WCB | 224WCB | 324WCB | 324WCB | 236WCB, dynamic braking |

King Pin Dia. (mm) | 3 1/2" | 3 1/2" | 3 1/2" | 3 1/2" | 3 1/2" |

Minimum ground clearance (mm) | 311 | 311 | 311 | 311 | 311 |

means not the first parameter

Product display

VIEW MORE

You may like

-

API standard second-hand workover rig oil drilling rig price

-

API standard oilfield drilling rig

-

API oil and gas drilling rig 2000m ZJ-20CZ oil well drilling rig

-

Crawler type 300m down-the-hole drilling rig water well second-hand LQ300 water well drilling rig for sale.

-

Rexroth Anvochi SJ PETRO, RG PETRO, DFXK, BOMCO, ZYT, HH control valves for drilling and workover rigs

-

Kerui High Quality Energy Oil Drilling and Workover Rig Desert Drilling Rig and Workover Rig

-

Oil Drilling Rig Equipment ZJ50DBS Oil Drilling Rig and Spare Parts DBS Power Sales Weight Electric Origin Model Center Year

-

Standard oil and gas well truck-mounted inclined well workover rig

-

Oil well drilling rig part of solid control equipment TC225 crown seat

-

Electric Drive Drilling Rig ZJ50/3150D Oil Drilling Rig Pipeline Oil Drilling Rig For Sale

Other Products

-

$1000000.00 / set

$1000000.00 / set -

$940000.00 / set

$940000.00 / set -

$5000.00 / set

$5000.00 / set -

$1000000.00 / set

$1000000.00 / set

Related Search

easy to operate for diesel generator sets

easy to operate light weight small

easy to operate machinery

truck mounted water well drilling rig model

truck mounted water well drilling rigs

truck mounted water well drilling rig

truck mounted water well drilling rig price

easy to us interfac suppliers

easy to clean ptfe mesh conveyor belt

easy to read books suppliers