Turnkey cell phone and car lithium battery recycling machine

-

Supplier: Henan Recycle Environmental Protection Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Andrew Zhang -

Price: $30000.00 /set -

Min. Order: 1 set

Product details

| Warranty: | 12 months, 1 year | After-sales service provided: | Engineers can service machinery overseas, free spare parts, online support, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support |

| Core components: | engine, motor | Showroom location: | Korea, UAE, South Africa, Nigeria, Malaysia, Vietnam, Saudi Arabia, Pakistan, India, Mexico, Spain, Thailand |

| place of origin; place of origin: | Henan, China | brand: | Recycle |

| Applicable industries: | Manufacturing, Energy & Mining, Other, Solid Waste Recovery | Core Components Warranty: | 1 year |

| Weight (kg): | 1470 | Supply capacity: | 20 turnkey cell phone and car lithium battery recycling machines per month |

| Health status: | new | Packaging Details: | 1). Machine Name: Turnkey Cell Phone and Car Lithium Battery Recycling Machine 2): Standard packing, wooden case or as customer's request |

| Local service location: | Malaysia, South Korea, Chile, UAE, Algeria, South Africa, Turkey, Vietnam, Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Spain, Thailand | application: | Lithium battery recycling machine |

| payment terms: | L/C, Western Union, T/T, MoneyGram, Cash or Alibaba Trade Assurance | Mechanical test report: | if |

| type: | Environmental protection machinery | Function: | Turnkey battery recycling machine |

| Main selling point: | competitive price | Video external inspection: | if |

| output: | precious metal | color: | customer request |

| port: | Qingdao or any port in China | Voltage: | According to your country voltage |

| Packaging Preview: | Power (kW): | 157 | |

| product name: | Turnkey cell phone and car lithium battery recycling machine | Marketing Type: | Hot Products of 2019 |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Raw materials: | Mobile phone, car lithium battery |

background

At present, the research on the recycling and utilization of waste lithium batteries mainly focuses on

Recovery of high value anode precious metals cobalt and lithium. Copper (content up to 35%) in the negative electrode of waste lithium batteries is an important raw material for production and is widely used. The carbon powder attached to it can be used as additives such as plastic and rubber. According to the structural characteristics of lithium batteries, our company adopts environmentally friendly physical

Separation process to achieve efficient separation and recovery of waste lithium batteries.

Recovery of high value anode precious metals cobalt and lithium. Copper (content up to 35%) in the negative electrode of waste lithium batteries is an important raw material for production and is widely used. The carbon powder attached to it can be used as additives such as plastic and rubber. According to the structural characteristics of lithium batteries, our company adopts environmentally friendly physical

Separation process to achieve efficient separation and recovery of waste lithium batteries.

Product Description

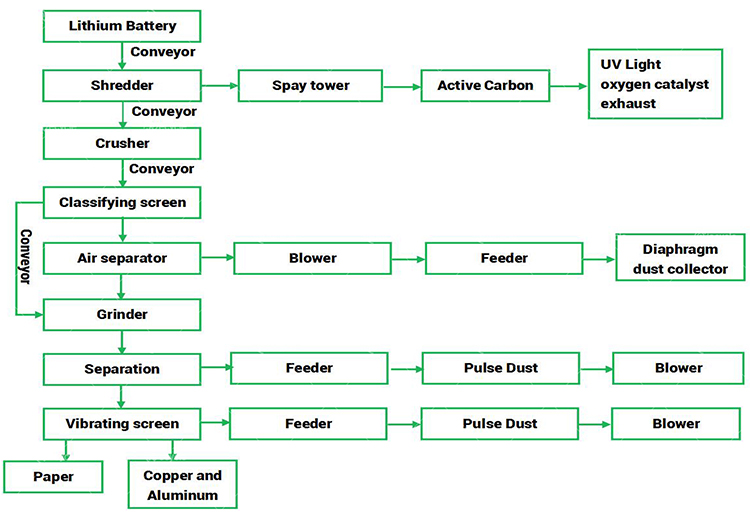

The pretreatment process of the lithium battery recycling plant mainly includes the following steps: after discharging the recycled waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

raw material

The lithium battery recycling plant is used to disassemble and recycle soft pack batteries, mobile phone batteries, shell batteries, cylindrical batteries, etc. Different types of lithium batteries have different recycling procedures. Please contact us for detailed configuration.

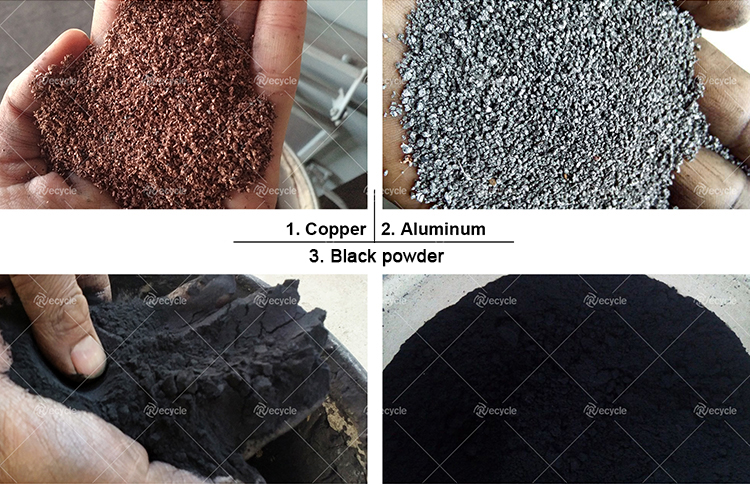

Final product

The plant's final products are graphite powder, lithium cobalt oxide, aluminum and copper.

Process flow

Shredder--Hammer Crusher--Pulverizer--Separator--Collector--Pulse Purifier--Classifying Screen--Magnetic Machine--Gravity Separator--High Pressure Blower

Shredder: Tear the lithium battery into small pieces.

Hammer Crusher: Used for secondary crushing of scraps.

grinder: For grinding of crushed materials.

grinder: For grinding of crushed materials.

Separator: Separate after grinding.

collector: Collect and release dust.

collector: Collect and release dust.

Pulse purifier (air purifier): Remove all dust generated during the operation of the entire system.

Category screen: The material sorted by the sieving machine, and the larger metal material is screened out.

magnetic machine: Separate nickel from metal.

magnetic machine: Separate nickel from metal.

Gravity Separator: The finer material is separated from the sieving machine, and the metal is completely separated.

High pressure blower: Make the whole system under negative pressure to collect materials and purify the air.

Environmental recycling equipment

technical parameter

Model | capacity | |

LDC-300 | 200-300 kg/h | |

LDC-500 | 500 kg/h | |

LDC-800 | 800 kg/h | |

LDC-1000 | 1T/H | |

LDC-1500 | 1.5T/H | |

LDC-2000 | 2T/H | |

working performance | ||

raw materials | Lithium Ion Battery | |

Finished goods | Mainly copper, aluminum, lithium cobalt oxide, graphite powder | |

notes:

Working voltage: 380±10V (415V, 440V can also be customized);

(If you need more detailed parameters and quotations, please contact us)

(If you need more detailed parameters and quotations, please contact us)

technical standard

Featured Items | Indicator requirements |

Recovery rate of metal aluminum | >98% |

powder recovery | >98% |

Metal aluminum powder content | <2% |

The content of metallic aluminum in the powder | <2% |

other | Including pollution-free dust collector |

Pass rate | 99% |

failure rate | <1% |

CMR | ≥1.67 |

Customer visit

equipment site

VIEW MORE

You may like

-

V-S30 Fully Automatic Scrap Copper Wire Granulator Recycling Machine Copper Recycling Machine

-

High performance small copper cable shredder mini cable shredder used copper wire shredder

-

High-quality PCB recycling equipment/PCB dismantling machine

-

BSGH Mini Cable Granulator Waste Cable Wire Separator Recycling Machine at 220 V with the most advanced technology and good quality

-

industrial iron ore crusher plant price

-

Shredder Double Shaft Shredder, Shredder, Waste Plastic Shredder

-

2022 Best Selling Cable Wire Granulator Grid Grinding Separator Recycling Machine

-

Factory direct sales metal pipe bender round pipe bender iron pipe bender

-

Double shaft scrap metal shredder used car shredding scrap metal shredder

-

Copper Wire Pelletizer Splitter/Small Copper Wire Pelletizer

Other Products

-

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$19000.00 / set

$19000.00 / set -

$30000.00 / set

$30000.00 / set -

$80000.00 / set

$80000.00 / set -

$80000.00 / set

$80000.00 / set -

$50000.00 / set

$50000.00 / set -

$80000.00 / set

$80000.00 / set -

$17500.00 / set

$17500.00 / set -

$5000.00 / set

$5000.00 / set