500 kg/h Car Lithium Ion Battery Recycling Plant

-

Supplier: Henan Recycle Environmental Protection Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Andrew Zhang -

Price: $30000.00 /set -

Min. Order: 1 set

Product details

| Package Preview: | ; | Video outgoing-inspection: | Provided; |

| Core Components: | Motor,Engine,Other; | Payment Terms: | L/C,Western Union,T/T,MoneyGram,Cash or Alibaba Trade Assurance; |

| Supply Ability: | 20 Sets per Month Cellphone Lithium Battery Copper Film Recycling Machine; | Brand Name: | RECYCLE; |

| Marketing Type: | Hot Product 2021; | Weight: | Depends On Capacity 500 kg/h Car Lithium Ion Battery Recycling Plant; |

| Place of Origin: | Other Country; | Weight (KG): | 14700 kg; |

| Model Number: | RSK-LDC 500; | Packaging Detail: | Name: 500 kg/h Car Lithium Ion Battery Recycling Plant A. Capacity 200-3000kg/h 500 kg/h Car Lithium Ion Battery Recycling Plant B. Standard Packing, Wooden case 500 kg/h Car Lithium Ion Battery Recycling Plant C. As Customer Requirements 500 kg/h Car Lithium Ion Battery Recycling Plant; |

| Voltage: | According To Your Country Voltage; | Production Capacity: | 500kg/h; |

| Key Words: | Battery Recycle Machine; | Application: | Lithium Battery Recycle; |

| Applicable Industries: | Recyclcing Machine; | Color: | Customer's Requirement 500 kg/h Car Lithium Ion Battery Recycling; |

| Type: | Environmental Protection Machinery,BATTERY RECYCLE; | Power: | As Requirements; |

| Machinery Test Report: | Provided; | Showroom Location: | Turkey,Viet Nam,Brazil,Peru,Indonesia,India,Spain,Thailand,South Korea,Chile,South Africa,Nigeria; |

| Warranty: | 12 Months 500 kg/h Car Lithium Ion Battery Recycling Plant,2 years; | Port: | Qingdao or any port of China; |

| Warranty of core components: | 1.5 years; | Condition: | New 500 kg/h Car Lithium Ion Battery Recycling Plant,New; |

| Raw Material: | Scrap Lithium ion Battery; | Product name: | 500 kg/h Car Lithium Ion Battery Recycling Plant; |

| Material: | Standard Packaging; |

BACKGROUND

At present, the research on the recycling of wastelithium batteries is mainly focused on the

recovery of high-value anode precious metals cobaltand lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is animportant production raw material widely used.Carbon powder adhered to it can be used asadditives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical

separation process to realize efficientseparation and recovery of waste lithium batteries.

recovery of high-value anode precious metals cobaltand lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is animportant production raw material widely used.Carbon powder adhered to it can be used asadditives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical

separation process to realize efficientseparation and recovery of waste lithium batteries.

Product Description

The pretreatment process of Lithium Batetry Recycling Plant mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

RAW MATERIALS

The lithium battery recycling plant is used for dismantling and recycling the Soft package battery, cellphone battery,Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration.

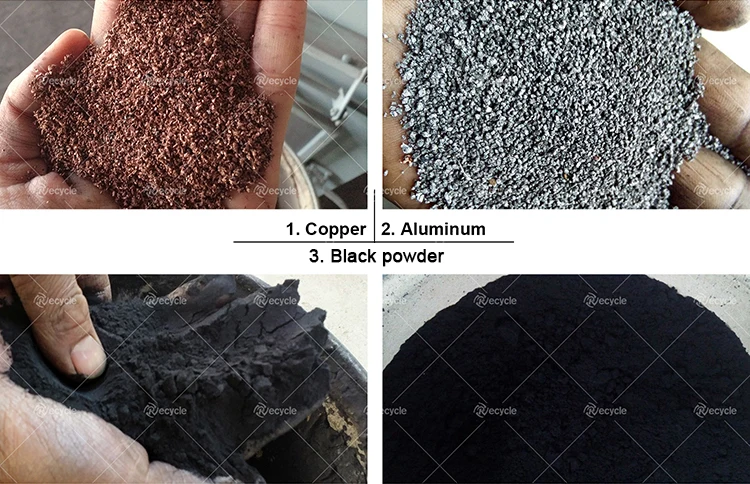

FINAL PRODUCTS

The final products of this plant is Graphite powder, Cobalt acid lithium,Aluminum and copper.

Technological Process

Shredder -- Hammer Crusher -- Grinder -- Separation Machine -- Collector--Pulse Purifier -- Classifying Screen -- Magnetic Machine --Gravity Separator -- High-pressure Blower

Shredder: Shredded lithium batteries into smaller pieces.

Hammer crusher: For the secondary crushing of shredded materials.

Grinder: For the grinding of the crushed materials.

Grinder: For the grinding of the crushed materials.

Separation Machine: Separate the materials after being ground.

Collector: Collect and release the dust .

Collector: Collect and release the dust .

Pulse Purifier (Air Cleaner): Clean all the dust produced during the operation of the wholesystem.

Classifying Screen:Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic Machine: Separate nickel from the metals.

Magnetic Machine: Separate nickel from the metals.

Gravity Separator:Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower: Keep the whole system in a negative state so as to collect the materialsand purity the air .

Environmentally Friendly Recycling Equipment

Technical Parameters

Model | Capacity | |

LDC-300 | 200-300 Kg/H | |

LDC-500 | 500 Kg/H | |

LDC-800 | 800 Kg/H | |

LDC-1000 | 1T/H | |

LDC-1500 | 1.5T/H | |

LDC-2000 | 2T/H | |

WORKING PERFORMANCE | ||

Raw Material | Lithium-ion Battery | |

Final Product | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder | |

NOTE:

Working voltage:380±10V(415V ,440V also can be customized);

(If you want more detailed parameters and quotations, please contact us)

(If you want more detailed parameters and quotations, please contact us)

TECHNICAL STANDARDS

Feature Item | Indicator Requirments |

Recovery Rate of Metallic Aluminum | >98% |

Powder Recovery Rate | >98% |

Content of Powder In Metal Aluminum | <2% |

Content of Metallic Aluminum In Powder | <2% |

Other | Contain dust collecter with not pollute |

Qualified Rate | 99% |

Failure Rate | <1% |

CMR | ≥1.67 |

Customers Visiting

Equipment Worksite

Packing and Delivery

Quality Assurance

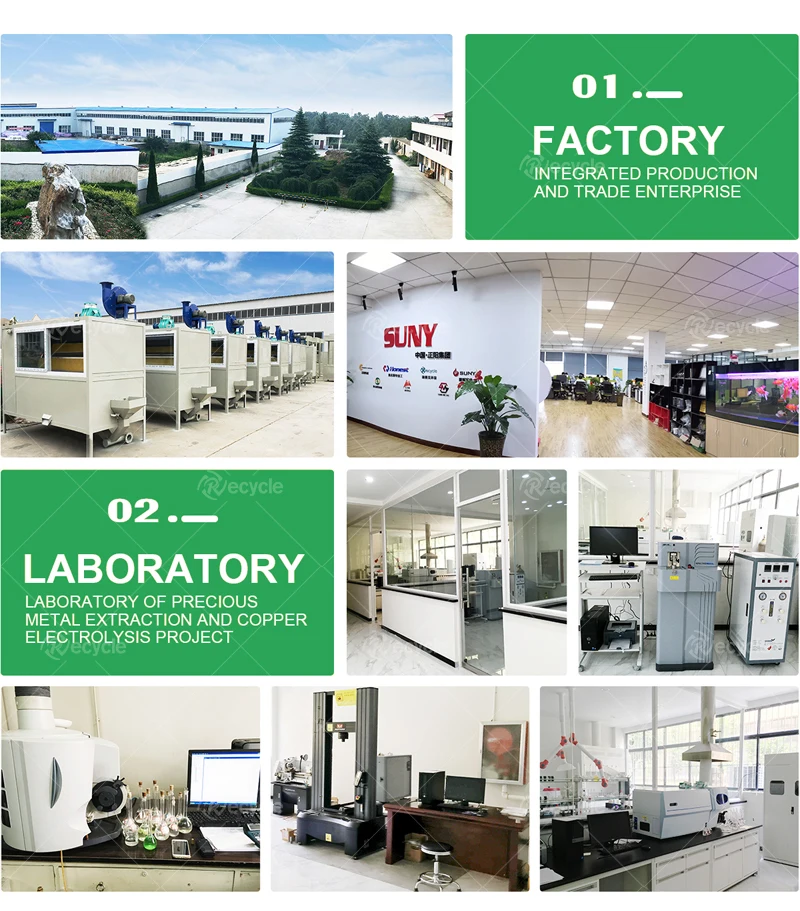

Company Show

As one of the largest E-waste and Other Solid Waste Metal Recycling Machine manufacturer, our factory can provide the whole solutions. Perfect after-sales service is provided and CE certification is provided for all products.

We can dispatch engineers to overseas to help you with installation, training if you need.

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

FAQ

Q: Why Choose Us?

According to the customers' special requirements,we provide the most suitable project design, process design and the purchase program. Guide customers to choose the best and economical plant, recover investment within short time.

You are welcome to visit our factory to test the machine. And we will customize the equipment strictly according to your special requirements and arrange the timely delivery.

We will provide one year warranty for our machine.According to your need,we will dispatch our engineers to your factory to guide the installation,commissioning and training your workers.

1). We are manufacturer with own factory for many years with CE Certification

2). With professional design and sales team, we can serve you perfect solution with competitive direct factory price.

3). Our machines are popular among customers around the world ( India, Pakistan, Spain, Italy, Korea, Mexico, UK etc).

Q: What Is Your Service?

1). Pre-Sale Service

According to the customers' special requirements,we provide the most suitable project design, process design and the purchase program. Guide customers to choose the best and economical plant, recover investment within short time.

2). Sales Service

You are welcome to visit our factory to test the machine. And we will customize the equipment strictly according to your special requirements and arrange the timely delivery.

3). After-Sale Service

We will provide one year warranty for our machine.According to your need,we will dispatch our engineers to your factory to guide the installation,commissioning and training your workers.

Q: How Do You Ensure The Machine Quality?

A: You can send your sample scrap materials to us and we will test the machine for you

without charging the fees. And we can send the machine test video to you. According to your time, you can pay a visit to our factory to test our machine.

without charging the fees. And we can send the machine test video to you. According to your time, you can pay a visit to our factory to test our machine.

Q: How About The Motor?

A: We use domestic Chinese-famous motors,but you can choose Siemens or other brand motor as your

requirement.

requirement.

VIEW MORE

You may like

-

Truck recycling container glove box garbage container large dumpster

-

Waste-to-energy power plants Municipal solid waste Household waste Hospital waste large-scale incinerators

-

Domestic Digester Plant

-

PE Underground Septic Tank 600L -2500L

-

20 yard Tube Roll Container

-

Cable copper wire recycling machine/copper wire recycling machine cable granulator for sale

-

High German Supplier Hydraulic Recycling Scrap Metal Compactor

-

Automatic classification line of municipal solid waste recycling plants

-

Sludge waste incinerator boiler pollution control smokeless medical waste incineration boiler manufacturer

-

Three-way catalytic cutting machine

Other Products

-

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$30000.00 / set

$30000.00 / set -

$19000.00 / set

$19000.00 / set -

$80000.00 / set

$80000.00 / set -

$80000.00 / set

$80000.00 / set -

$50000.00 / set

$50000.00 / set -

$80000.00 / set

$80000.00 / set -

$17500.00 / set

$17500.00 / set -

$5000.00 / set

$5000.00 / set