312 ton steel open cooling tower for commercial building HVAC system

-

Supplier: Wuxi Sanjiu Cooling Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Angela Luo -

Price: $3999.00 /set -

Min. Order: 1 set

| Packaging Details: | Standard packaging ensures proper protection during transport | Main selling point: | competitive price |

| payment terms: | letter of credit, wire transfer | Health status: | new |

| port: | Shanghai/Ningbo | Mechanical test report: | if |

| Core Components Warranty: | 1 year | Packaging Preview: | |

| place of origin; place of origin: | Jiangsu, China | Marketing Type: | normal product |

| After-sales service provided: | Engineers can repair machinery overseas | Supply capacity: | 30 sets per month |

| brand: | Sanjiu | Applicable industries: | Hotels, Manufacturing Plants, Food and Beverage Plants, Construction Engineering, Energy and Mining |

| weight: | 1800kg | Nominal cooling capacity: | 312 tons |

| Voltage: | 380V~480V | Cooling Type: | Crossflow |

| Filler: | MX75 PVC | Showroom location: | not any |

| Material: | Superdyma & Copper Tube | strength: | 5.5kW |

| Video external inspection: | if | Core components: | motor |

| Dimensions (L*W*H): | 1980*3910*3200 | Warranty: | 18 months |

| Certification: | CE;ISO9001:2008 | Shell material: | Mg-Al-Zn alloy coated steel |

312 Ton Steel Open Cooling Tower for Commercial Building HVAC System

Note: All data are under the condition of 25.5 ℃ humidity temperature.

If the conditions change in any way, the data changes.

|

model. |

GOM 0120Q-1 |

|

|

Limited Data |

312 m³/h, adjustable according to different temperatures |

|

|

Cooling range |

From 65~55℃ to 45~35℃ |

|

|

Pipe diameter |

Enter diameter (mm) |

DN200*2 |

|

Output diameter (mm) |

DN200 |

|

|

rated power |

Fan(KW) |

5.5 |

|

Shell/Tower Body Material |

Superdyma (imported from Japan) |

|

|

Filler |

MX-75 PVC |

|

|

installation method |

Modular design for easy installation |

|

structure and enclosure

The tower shell is made of special alloy (Mg-Al-Zn) coated steel sheet, originally imported from Nippon Steel or Posco. These panels exhibit excellent corrosion resistance and heal themselves when scratched during use. Panels are bolted and sealed to ensure water tightness. The enclosure is equipped with maintenance access doors for easy internal inspection.

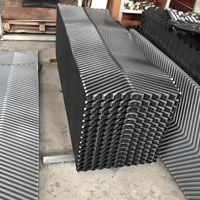

Drift Eliminator

The water eliminators are vacuum formed from PVC sheets into special shapes that allow minimal water retention and negligible pressure drop. Eliminators consist of tractable parts.

Axial fan section

Axial fans feature lightweight aluminum alloy blades that are perfectly balanced and connected to a weatherproof electric motor. The fan housing is a steel cylinder that draws air vertically, avoiding the risk of recirculation. The tip speed of the impeller is limited to keep noise levels within acceptable limits.

Wet Deck Fill

The filler is made of flame retardant PVC sheet, the shape of which is specially designed to optimize the turbulence of countercurrent fluids. For moderately polluted waters, we can provide infills with enlarged grids. All raw materials are original grades from approved suppliers.

water distribution system

Main headers - 1 to 3, depending on model - made of steel and hot-dip galvanized. Auxiliary headers are made of PVC and use non-clogging nozzles in special rubber compounds or resins, depending on the model.

basin

Made of the same alloy-coated steel for the collection of cooling water, the basin is equipped with:

- water outlet with easy-to-use filter,

- Drain and overflow connections,

- water connection with float valve,

- PP honeycomb air intake and draft grille, low pressure drop.

- Drain the pipe with a regulating valve to prevent salt concentration in the water.

Finish

Standard cooling towers come in an alloy coated steel finish and do not require any additional painting unless other colors are ordered as optional items.

- Quick response within 12 hours

-Provide professional and economical cooling solutions for every customer

- Best value for money in the world

-

Green round cooling tower fill cooling tower PVC fill

-

FRP/steel structure square cooling tower

-

125 tons open cooling tower heat exchange facility

-

Cross cooling tower PVC film filling material

-

PVC Cooling Tower Filler/High Quality Cooling Tower Filler

-

PP PVC Cooling Tower Fill/Plastic Fill Panel/Cooling Tower Fill

-

Closed cooling tower price cooling tower injection molding machine cooling tower

-

Inexpensive Counter Flow 250 Ton Data Center Closed Circuit Cooling Tower

-

Water cooling tower, medicine, chemical industry, food, injection molding, electronics, textile, shopping malls, hotels, etc.

-

Hot Sale Factory Direct Price Material Pvc S Wave Iso9001:2008 Certification Cooling Tower Fill