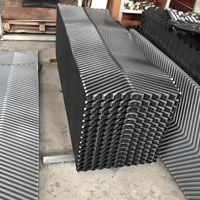

PP PVC Cooling Tower Fill/Plastic Fill Panel/Cooling Tower Fill

-

Supplier: Pingxiang Nanxiang Chemical Packing Co., Ltd. -

Region: Jiangxi, China -

Contact: Ms Jenny Liu -

Price: $0.50 /piece -

Min. Order: 1 piece

| Showroom location: | not any | brand: | Nanxiang |

| Health status: | new | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Material: | polyvinyl chloride, polyvinyl chloride | Dimensions (L*W*H): | custom made |

| Applicable industries: | Building materials store, machinery repair shop, household | usage: | wastewater treatment |

| color: | Black | Origin: | Jiangxi, China |

| Supply capacity: | 100000 sheets per month | Video shipment inspection: | if |

| strength: | not applicable | Marketing Type: | normal product |

| port: | Shanghai, Shenzhen, Ningbo | Core component warranty: | 1 year |

| Mechanical test report: | not available | Main selling points: | high accuracy |

| weight: | customer inquiry | Warranty: | 1 year |

| After warranty service: | online support | Core components: | engine |

| Local service location: | not any | Certification: | ISO9001:2008,ISO9001:2008 |

| product name: | PP PVC Cooling Tower Fill/Plastic Fill Sheet/Cooling Tower Fill | Voltage: | not applicable |

| Cooling type: | Crossflow | Packaging Details: | strap or wooden box |

| After-sales service provided: | Does not provide overseas services |

PP PVC Cooling Tower Fill/Plastic Fill Sheet/Cooling Tower Fill

Cooling tower fill is one of the most important components for gas and water exchange in a cooling tower. It is the main component to improve the efficiency of the cooling tower and ensure the economical and safe operation. With the development of the plastics industry, the "S"-shaped step wave and oblique wave of the counterflow tower spraying plastic packing have the advantages of good heat dissipation, small ventilation resistance, durability, and easy foothold, and are widely used in different types of large and medium-sized plants. , Small cooling tower.

Cooling tower fill features:

1. Improved water distribution

2. High thermal performance

3. Materials meet Cooling Tower Institute

4. Mainly suitable for countercurrent filling.

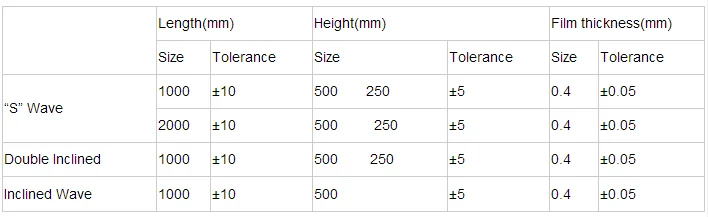

Technical data:

MX Fill is available in MX75 configurations and higher performance MX625 configurations. MX is a film cooling tower fill that disperses water in a thin film that flows over large vertical surfaces, promoting maximum exposure to the airflow. This type of fill provides more water surface exposure per cubic foot than splash-type fill.

MX fill incorporates a highly efficient honeycomb water eliminator integrally formed within the fill sheet. These eliminators reduce column drift emissions by a factor of ten or more compared to previous designs! Less drift means tower owners save on water bills and water treatment chemicals.

This infill virtually eliminates the nuisance that drift points cause to adjacent buildings and property. For further cost savings, the dehydrator exhausts air directly to the fan. Exhaust air travels in the correct direction as it exits the deaerator, which translates to lower fan power.

The louvres are also integrally formed within the filler panels, preventing water from escaping and ensuring precise air distribution in conditions of highly variable airflow. Unlike towers with separate external louvers, this fill is virtually impervious to freezing, even in extremely cold weather.

Thermoformed from PVC, MX Fill has a flame spread rating of less than 25 per ASTM E-84 and is considered self-extinguishing. Therefore, there is little risk of fire damage.

We have many years of experience in exporting cooling tower fill, and we specialize in installation and production.

Technical data:

Features of cooling tower fill:

1. More cooling capacity in a given space

2. Provide low clogging design

3. Provide bottom support or suspension design

4. Can obtain FM certification

5. Cross flow and counter flow design

6. Integrated louvers and eliminators are available for cross-flow designs.

7. High temperature resistant design available

8. One piece, full height counterflow design available

1. Quality:Excellent quality is our first pursuit, and our quality control team strictly controls the quality.

2. Capacity:Continuously introduce new equipment to meet customer production needs and market changes

3. Team:Focusing on chemical packaging for more than 12 years, the professional export team provides customers with comprehensive services

4. Efficiency:24-hour online service to solve all your problems.(Email, Trademanager, Skype, MSN, WhatsApp, Phone),Factory direct prices will be available within 24 hours.

5. Customization:Size and shape can be made according to customer requirements

6. Payment method:You can choose flexible and diverse payment methods to make it more convenient for you

-

Green round cooling tower fill cooling tower PVC fill

-

FRP/steel structure square cooling tower

-

125 tons open cooling tower heat exchange facility

-

Cross cooling tower PVC film filling material

-

PVC Cooling Tower Filler/High Quality Cooling Tower Filler

-

Closed cooling tower price cooling tower injection molding machine cooling tower

-

Inexpensive Counter Flow 250 Ton Data Center Closed Circuit Cooling Tower

-

Water cooling tower, medicine, chemical industry, food, injection molding, electronics, textile, shopping malls, hotels, etc.

-

Hot Sale Factory Direct Price Material Pvc S Wave Iso9001:2008 Certification Cooling Tower Fill

-

Factory Price High Temperature Cooling Tower China Manufacturers Air Compressor Plastic Injection Molded Cooling Tower

Other Products

-

$0.15 / piece

$0.15 / piece