Closed cooling tower price cooling tower injection molding machine cooling tower

-

Supplier: Laizhou City Haolong Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Jacky Sheng -

Price: $1500.00 / 1 - 1 sets

$1400.00 / >=2 sets -

Min. Order: 1 set

Product details

| After-sales service provided: | online support | color: | customer request |

| Marketing Type: | New Products 2021 | product name: | FRP FRP Cooling Tower |

| Core components: | PLC, engine, motor, pressure vessel, water pump | usage: | Cooling Tower |

| Health status: | new | Applicable industries: | Building Materials Store, Machinery Repair Shop, Manufacturing Plant, Food & Beverage Plant, Farm, Restaurant, Construction, Energy & Mining, Food & Beverage Store, Other, Other |

| shape: | round square | Mechanical test report: | if |

| Video shipment inspection: | if | brand: | good dragon |

| water flow: | 25~300 tons/hour | Key words: | Cross closed cooling tower |

| Main selling points: | high accuracy | Warranty: | 1 year |

| Showroom location: | not any | Package preview: | |

| Voltage: | 380V | Material: | specific |

| Cooling type: | countercurrent | Application fields: | Industrial Closed Circuit Cooling Tower |

| Packaging Details: | standard | weight: | 880 kg |

| strength: | 1.5KW | Origin: | Shandong China |

| Core component warranty: | 1 year | Supply capacity: | 3 sets per month |

| application: | industrial cooling system | Coil Material: | stainless steel 304 |

| Key words: | Water cooling tower system | Local service location: | not any |

| payment terms: | L/C, T/T | After warranty service: | online support |

| port: | Qingdao Port |

Product Description

Factory Supply Water Treatment Cooling Towers

The waste heat generated in industrial production or refrigeration process is usually taken away by cooling water. The function of the cooling tower is to exchange the cooling water with the air in the tower, so that the waste heat is transferred to the air and dissipated into the atmosphere. For example, in a thermal power plant, the boiler heats water into high-temperature and high-pressure steam, which drives the steam turbine to do work, so that the generator generates electricity. After the steam turbine is working, the waste steam is discharged into the condenser for heat exchange with cooling water, condensed into water, and then pumped back to the boiler for recycling. During this process, the waste heat of the exhaust steam is transferred to the cooling water to increase the temperature of the water. The cooling water with residual heat transfers heat to the air in the cooling tower, and is discharged into the atmosphere through the air duct. Cooling tower application range: mainly used in air conditioning cooling system, refrigeration series, injection molding, tanning, foaming, power generation, steam turbine, aluminum profile processing, air compressor, industrial water cooling and other fields, most of which are used in air conditioning refrigeration, refrigeration, Plastic and chemical industries.

Technical Parameters

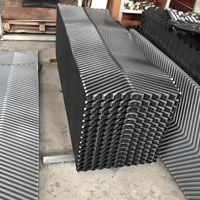

product display

Design Features:

1. The circular counter-flow cooling tower adopts a bottle design with the smallest windward volume. Cooling tower components are carefully designed and manufactured, light in structure, easy to assemble, sturdy and durable, the performance of the cooling tower has been tested and high in efficiency. 2. Tower body: It is made of fiberglass composite material (commonly known as FRP). The surface rubber coating and pigments are imported raw materials, and its color contains anti-ultraviolet stabilizer. The surface of the tower can reach a mirror surface, which is anti-aging, enduring and particularly shiny. 3. Wind blades: multi-blade axial flow blade design, there are two kinds of high-grade aluminum alloy and ABS. After balance correction, it runs smoothly and quietly, with low noise and low energy consumption. The blade angle is adjustable. The air volume can be adjusted according to the demand, and the angle of the fan blade can be adjusted to give full play to the maximum exhaust effect. 4. Motor: The fully sealed cooling tower motor is 380V/3ф/50Hz, with good waterproof performance, and can be used safely in high temperature and humid environments. Our company can also customize special motors for cooling towers with different voltages and frequencies according to customer requirements. 5. Water distribution system: high-performance automatic rotary water distributor, made of stainless steel, bronze alloy or ABS material, durable, uniform water distribution, low water supply pressure. 6. Heat dissipation material: Standard and medium-temperature cooling towers are made of high-grade PVC, which has a large growth coefficient of heat dissipation area, good water distribution, large disturbance, and high heat dissipation performance when water flows through the film; high-temperature cooling towers use high-grade PP materials that can withstand high temperatures of 90 degrees. The surface is specially processed into waves and patterns, with large spacing, not easy to scale and block, and overcomes the problem of poor circulating water quality. 7. Steel parts: all are protected by rust-removing galvanized anti-corrosion paint, corrosion resistance, high strength, convenient assembly and beautiful surface.

VIEW MORE

You may like

-

Green round cooling tower fill cooling tower PVC fill

-

FRP/steel structure square cooling tower

-

125 tons open cooling tower heat exchange facility

-

Cross cooling tower PVC film filling material

-

PVC Cooling Tower Filler/High Quality Cooling Tower Filler

-

PP PVC Cooling Tower Fill/Plastic Fill Panel/Cooling Tower Fill

-

Inexpensive Counter Flow 250 Ton Data Center Closed Circuit Cooling Tower

-

Water cooling tower, medicine, chemical industry, food, injection molding, electronics, textile, shopping malls, hotels, etc.

-

Hot Sale Factory Direct Price Material Pvc S Wave Iso9001:2008 Certification Cooling Tower Fill

-

Factory Price High Temperature Cooling Tower China Manufacturers Air Compressor Plastic Injection Molded Cooling Tower

Other Products

-

$1500.00 - $2500.00 / set

$1500.00 - $2500.00 / set -

$600.00 - $1300.00 / set

$600.00 - $1300.00 / set -

$645.00 / set

$645.00 / set -

$500.00 / set

$500.00 / set -

$2000.00 / set

$2000.00 / set -

$1589.00 - $1999.00 / set

$1589.00 - $1999.00 / set -

$1800.00 - $2000.00 / set

$1800.00 - $2000.00 / set -

$1800.00 - $2000.00 / set

$1800.00 - $2000.00 / set

Related Search

injection molding machine price

plastic injection molding machine

hand plastic injection molding machine

injection molding machine

injection molding machine in malaysia

injection mold machine

horizontal rubber injection molding machine

inject molding machin for cap suppliers

pvc preform injection molding machine

pet bottle preform and cap injection molding machine