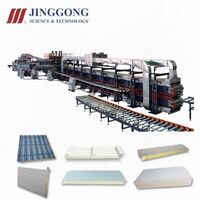

Automatic Continuous Sandwich panel Production line

-

Supplier: Sussman Machinery (wuxi) Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Spring Wu -

Price: $108000.00 / 1 - 1 sets

$101000.00 / 2 - 4 sets

$98000.00 / >=5 sets -

Min. Order: 1 set

| Place of Origin: | Jiangsu, China; | Warranty: | 1 Year; |

| Showroom Location: | Morocco,Argentina,Chile,Colombia,South Africa,Malaysia,Australia,Turkey,United States,Italy,France,Peru,Indonesia,Mexico,Russia; | Machinery Test Report: | Provided; |

| Sheet thickness: | 0.4-0.8mm; | Material of roller: | 40Cr; |

| Specification of sprocket: | 1 inch; | Local Service Location: | Malaysia,Kenya,Argentina,Chile,Colombia,Romania,Nigeria,Canada,France,Germany,Peru,Mexico,Russia,Thailand; |

| Speed of roll forming: | 12-15m/min; | Transmission equipment: | cycloid redcking gear box; |

| Diameter of the shaft: | 50mm; | Warranty of core components: | 1 Year; |

| Motor Power: | 11KW; | Hardness of shaft: | HB220-250°; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Brand Name: | Sussman; | Condition: | New; |

| Marketing Type: | New Product 2020; | Core Components: | 报警锁; |

| Port: | Shanghai; | Width Adjustable range: | 600-1250mm; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Supply Ability: | 10 Sets per Month; | Packaging Detail: | Naked; |

| Video outgoing-inspection: | Provided; | Package Preview: | ; |

Roll forming machine

Motor Power of:up panel 4KW,down panel 11KW

Speed of roll forming:12-15m/min

Material of roller:40Cr

The surface of roller is coated by chrome, thickness:0.05mm

The way of width adjust of roll forming machine:Straight track, silk pole, reducer motor adjustable

Width Adjustable range :( 600-1250mm)

Sheet thickness :( 0.4-0.8mm)

Structure:Arm type adjustable,support roller in the middle

Diameter of the shaft:50mm

Specification of sprocket:1 inch

Hardness of shaft:HB220-250°

Transmission equipment:cycloid redcking gear box

Roll station :according to the panel profile

Diameter of shaft of Hidden-joint roof panel roll forming machine:75mm

Structure of roll forming machine: profile steel

Change type of rollers:Whole change

Profiles

Main Machines & Technical Data

A. Un-coiler

1)Motor Power:3KW

2)Hydraulic Power:2.2KW

3)Raw material:Color steel sheet, Aluminum sheet

4)Inner diameter of coil:φ500mm-φ600mm

5)Out diameter of coil:φ1200mm

6)Weight of coil:10T

7)Thickness of sheet: 0.4-0.8mm

8)Width of sheet: 1250mm

9)Speed of uncoil: 1.5-12m/min

10)Hydraulic pressure: 6.3Mpa

B. Coil car

1)Hydraulic cylinder lift stroke:up panel 0.5m,down panel 0.5m

2)Coil car stroke:2.5m

3)Pressure of hydraulic system:6.3MPa

Two sets of steel sheet transverse cutting machines:

1) hydraulic

2) cut steel sheet according to certain length.

3) Two sets of PVC film covering device which applies the PVC film onto the steel sheet.

Sussman hereby solemnly promises: We implement the “three guarantees” service policy for any equipment sold by Sussman, provide free of charge installation guidelines, commissioning and maintenance of the equipment, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipment, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipment:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipment, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Sussman will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Sussman is doing the installation and test running of the equipment for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), then, upon the Buyer’s request, Sussman will eliminate the failure;

4. Sussman will inform all its Buyers about any upgrades and significant product improvements. Sussman will provide equipment modifications based on their costs. Sussman will provide Buyers with high-quality after-sales services in a careful and responsible attitude, provide very strong guarantee for the Buyer’s normal production.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc