Batch Mix SAP64 Stationary Asphalt Mixing Plant For Sale

-

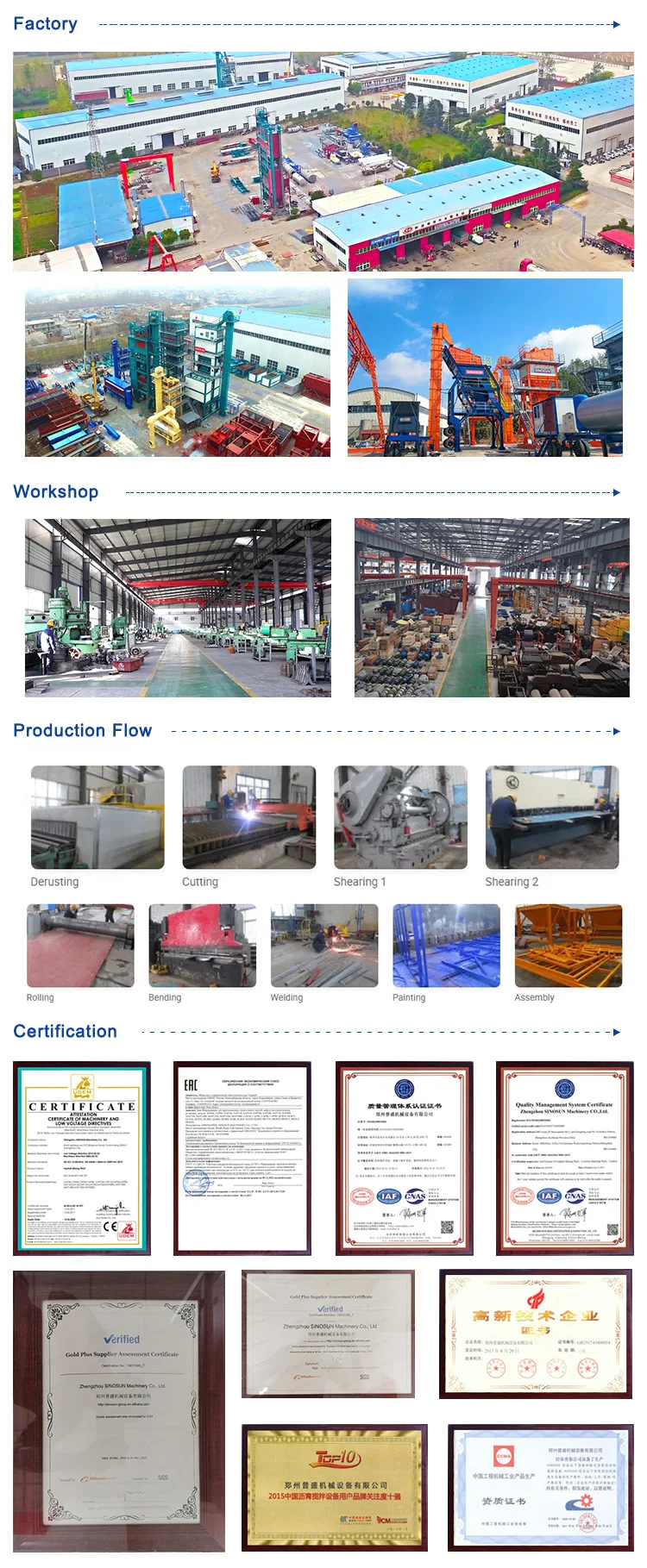

Supplier: Zhengzhou SINOSUN Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Sinosun Li -

Price: $150000.00 /unit -

Min. Order: 1 unit

| Application: | Construction Areas; | Power: | 154-860kw; |

| Dust Collecting Model: | Gravity dust collector+ NOMEX Bag House Dust Filter; | Warranty of core components: | 1 Year; |

| Marketing Type: | Ordinary Product; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Cash; |

| Supply Ability: | 5 Units per Month; | Machinery Test Report: | Provided; |

| Emission Concentration: | ≤20mg / Nm3; | UNIQUE SELLING POINT: | High operating efficiency; |

| Showroom Location: | Egypt,Philippines,Russia,Thailand,Malaysia,Morocco; | Weight: | 50000 kg; |

| Package Preview: | ; | Video outgoing-inspection: | Provided; |

| Capacity: | 64TPH; | Product name: | Batch Mix SAP64 Stationary Asphalt Mixing Plant For Sale; |

| Mixing Type: | Batching type, hot mix asphalt plant; | Temperature of finished product(℃): | 140-180; |

| Control system: | PLC+colorized Touching Screen; | Port: | Shanghai,Qingdao,Tianjin,or other China port; |

| Burner: | oil/coal/gas burner; | Packaging Detail: | Batch mix SAP64 stationary asphalt mixing plant need 7 units of 40HQ Container.; |

| Brand Name: | SINOSUN; | Dimension(L*W*H): | -; |

| Mixer capacity: | 800kg/batch; | Applicable Industries: | Building Material Shops,Manufacturing Plant,Construction works ; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Condition: | New; |

| Place of Origin: | Henan, China; | Warranty: | 1 Year; |

| Voltage: | 220V/380V-50Hz; |

Batch Mix SAP64 Stationary Asphalt Mixing Plant For Sale

Advantages of SAP64 stationary asphalt mixing plant

1. SAP series stationary asphalt mixing plant, hot mix asphalt mixing plant adopts modular structure, 3d drawing software of three-dimensional design, the layout can be combined to form a variety of configuration according to the construction requirements.

2. Smaller occupied working area, compact structure, it solves the difficulties due to lack of space.

3. Simple foundation, easy to be installed and maintenance, easy-transportation and transfer.

4. Rational layout, novel and decent appearance.

5. 64-320t/h hot mix bitumen mixing plant owns more accurate weighing system.

6. Energy saving, environment protection, safe and easy for operate.

7. Main reducers/bearing/air system/weighing/PLC can adopt international famous brand according to the client’s demand.

Main parameters of Batch Mix SAP64 Stationary Asphalt Mixing Plant

| Model | SAP64 |

| Installation Power(kw) | 154 |

| Rated Capacity(T/H) | 64 |

| Cold aggregate kinds | 4*6.5m3 |

| Drying drum Length/Diameter |

6.5m * ∅1.5m |

| No. of screen layers | 4 layers |

| Vibrating screen | Double Italy OLI Brand Vibrator Liner type |

| Mixing period(s) | 45 |

| Capacity of mixer(kg) | 800 |

| Fuel Consumption | ≤6.5kg/T finished product |

| Fuel type | Heavy oil/Diesel/Coal/Natural gas/Liquefied petroleum gas |

| Dust Collecting Model | Gravity dust collector+ NOMEX Bag House Dust Filter |

| Control method | Manual / Automatic |

| Temperature of finished product(℃) | 140-180 |

| Emission Concentration | ≤20mg / Nm³ |

| Finished product silo | 20/40/60/80/100/120/200T Bottom Type(Optional) |

For over years, we supplied the asphalt industry with high quality asphalt batching plant parts, mobile asphalt mixing plant,continous asphalt mixing plant and other reletaed products.

Our asphalt plant products are cost effective, user friendly, easy to maintain and strong after - sales services.

Now these asphalt plant products have been widely used in home and abroad road construction project, such as Russia, USA,Thailand, Romania , Poland , Brazil , Philippines , Indonesia, Peru, Canada, Bangladesh etc. In Africa , we have exported to Ethiopia , Angola , Algeria and Libya etc.

|

|

|

| 40-400TPH Stationary Asphalt Plant | 40-160TPH Mobile Asphalt Plant | 20-120TPH Drum Mix Asphalt Plant |

|

|

|

| 6-10TPH Emulsion Bitumen Plant | 4-10 TPH Bitumen Melting Machine | Bitumen Tank for Asphalt Plant |

SINOSUN is one of China’s dominant and professional manufacturers and exporters of Precisioned Asphalt Mixing Plants and related asphalt plant equipment.

We mainly supply:

1.Stationary asphalt mixing plant (SAP series)

2.Recycle asphalt mixing plant (SR series)

3.Mobile asphalt mixing plant ( MAP series)

4.Continuous asphalt mixing plant (CAP series)

5.Twin-shaft asphalt mixing plant (QLB series)

6.Twin-drum asphalt mixing plant (SLB series)

7.Emulsion Bitumen Plant (RH series)

8.Bitumen Melting Machine (DT series)

Q:Which countries your equipment have been exported?

A:Thailand, Philippines, Indonesia, Myanmar, Russia, Bangladesh, Kazakhstan, Uzbekistan, Russia, Romania, Somalia, Kenya, Malawi, Nigeria, Togo, Mozambique, Oman, South Africa, America, Peru, Chile, Colombia, Venezuela, Australia, etc.

Q:How many workers are needed to operate one set of asphalt plant?

A:1 loader operator, 1 mechanical, 1 electrician, 1 supervisor ,1 the operator of the whole plant.

Q:How many days are used for installation of one set asphalt plant?

A:Around 20-30 days, according to local situation.

Q:Do you provide overseas erection and training service?

A:Yes, we can send experienced engineers to your country, guide erection and commissioning and train your workers how to operate the plant.

Q:How long is the delivery time?

A:30-40 days, according to different configuration. We promise to delivery on time.

Q:Can you sent me some spare parts freely?

A:Some spare parts will be sent to you together with asphalt plants freely.

Q:How to go to your asphalt plant factory easily?

A:Our city has airport. If by air, you can fly from Guangzhou/Beijing/Shanghai no more than 2 hours. Also you can fly to Zhengzhou, we send car to pick you up there.

Q:Can I visit your factory?

A:Of course. We warmly welcome you to visit our factory. And we provide you great services like airport pick up, hotel booking, etc.

Q:How long is the warranty of your asphalt plant?

A:12 months

Q:What payment terms you accept?

A:We accept T/T, L/C,D/A,D/P, Western Union, MoneyGram and other ways according to the practical situation.

Get the quotation of asphalt mixing plant, welcome contact us at any time.

Pls following us for more information of asphalt plant and related equipment.

-

40TPH Mobile Asphalt Mixing Plant

-

Portable asphalt mixer asphalt hot recycling production pavement repair vehicle

-

Jinwang small mobile asphalt mixer road construction machinery concrete mixer

-

China famous brand 1650KG mixing capacity asphalt mixing plant SLB1500X8 for sale

-

Sell second-hand NIKKO NB1600 asphalt mixing plant

-

Mini Portable Cold Asphalt Mixer / Asphalt Mixing Plant Price / Asphalt Drum Mixing Plant 10t/h

-

asphalt mixer, asphalt mixer for mixing plant

-

UNUQUE GROUP Production 80TPH Mobile Asphalt Plant For Sale

-

20T/H - 100T/H Hot Mixing Plant Drum Mixing Asphalt Plant For Sale Continuous Asphalt Plant Price Mobile Asphalt Mixing Plant

-

LB2000 160t/h Asphalt Mixing Plant

Other Products

-

$10000.00 / set

$10000.00 / set -

$50000.00 / set

$50000.00 / set -

$35000.00 / set

$35000.00 / set -

$45000.00 / set

$45000.00 / set -

$250000.00 / set

$250000.00 / set -

$10000.00 / set

$10000.00 / set -

$30000.00 / set

$30000.00 / set -

$45000.00 / set

$45000.00 / set -

$400000.00 / set

$400000.00 / set -

$200000.00 / set

$200000.00 / set