PCB pick and place machine and mini smt chip mounter for LED machine with high speed

-

Supplier: Wenzhou Zhengbang Electronic Equipment Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Zhou -

Price: $4050.00 /set -

Min. Order: 1 set

Product details

| Brand Name: | HUAQIZHENGBANG; | After-sales Service Provide: | Overseas service center available; |

| Warranty of core components: | 1 Year; | Max pcb size: | 320x450 mm; |

| Core Components: | PLC; | Showroom Location: | Russia,Thailand,South Korea; |

| Theoreticall mounting: | 7000PCS/h; | Application element: | RC,LED,Chip; |

| Visual camera: | CCD high-defintion camera; | Condition: | New; |

| Mounting nember: | 2PCS; | Machinery Test Report: | Provided; |

| Single gross weight: | 97.000 KG; | Type: | Vacuum Pump; |

| Voltage: | AC220V ±10% 50Hz; | min pcb size: | 10x10; |

| Selling Units: | Single item; | Certification: | CE; |

| Single package size: | 120X85.5X58 cm; | Video outgoing-inspection: | Provided; |

| Power: | 230W; | Place of Origin: | Zhejiang, China; |

| Weight: | 85kg; | Marketing Type: | Ordinary Product; |

| Local Service Location: | Russia,Thailand,South Korea; | Warranty: | 1 Year; |

| Dimension(L*W*H): | 990x730x375 mm; | After Warranty Service: | Video technical support,Online support; |

| NW: | 83kg; | Applicable Industries: | LED lamb/PCB assembly line; |

| After-sales Service Provided: | Video technical support,Online support; | Function: | PCB Prototype Led Assembly Line; |

Product Description

Product Specification | ||||||||

System | Project | Content | ||||||

Mounting system | Mounting numbers | 2 pcs | ||||||

Precision | 0.025mm | |||||||

Theoretical speed | 6500 pcs/h | |||||||

Normal speed | 5000 pcs/h | |||||||

Visual speed | 3500 pcs/h | |||||||

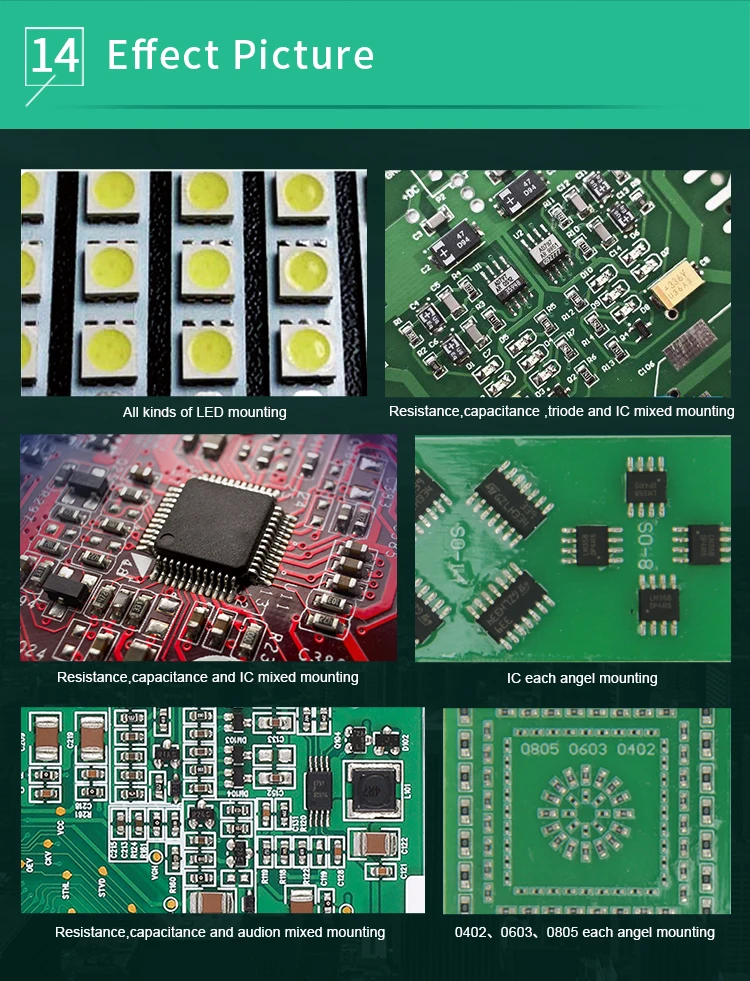

Applicable element | RC( 0402 , 0603 , 0805 , 1206 etc) | |||||||

LED lamp beads (0603,0805,3014,5050 etc) | ||||||||

Chip ( SOT , SOP , QFN , BGA etc) | ||||||||

PCB | Minimal Size | 10 x 10 mm | ||||||

maximum size | 320 x 450 mm (no try) | |||||||

320 x 220 mm( with try) | ||||||||

Thickness | ≤ 1 mm | |||||||

Wraping allowable value | ≤ 2 mm | |||||||

Feeder | Quantity | 27 pcs | ||||||

8 mm | 20 pcs | |||||||

12mm | 4 pcs | |||||||

16 mm | 2 pcs | |||||||

24 mm | 1 pcs | |||||||

Preposition IC | 10 pcs | |||||||

Tubular material feeder | Zhengbang dedicated five tubular materials feeder one(optional) | |||||||

X / Y / Z axis | X/Y axis moving range | 430 x 530mm | ||||||

Z axis moving range | 10 mm | |||||||

Visual Camera | Quantity | 2 pcs ( parts camera, PCB camera) | ||||||

Recognition capability | MAX 20 x 20mm | |||||||

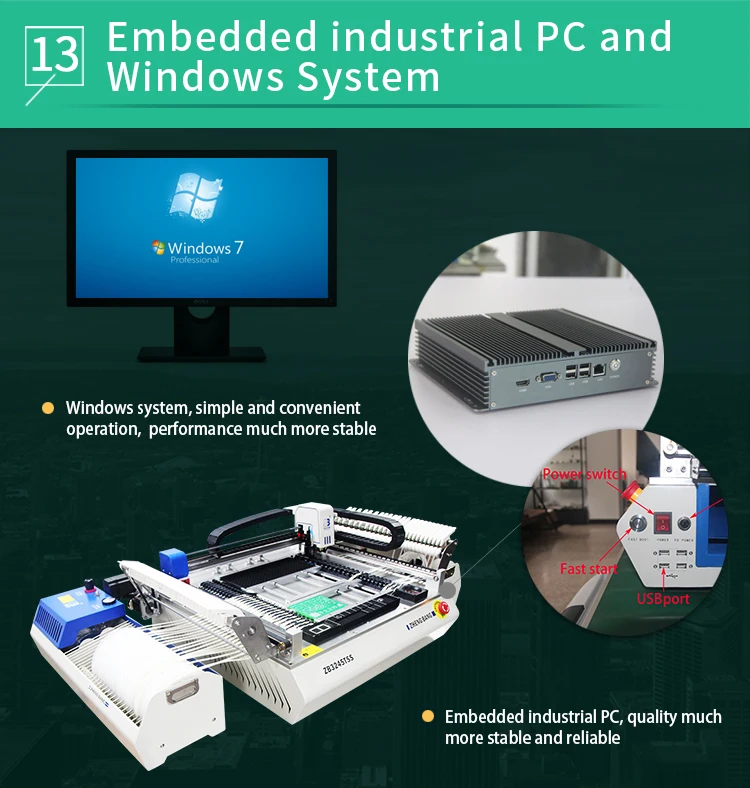

Control system | Syetem | Microsoft WIN7 | ||||||

file format | CSV, TXT | |||||||

Air pressure | 0.4 Mpa | |||||||

Basic parameter | Power | 150W | ||||||

Power supply | AC220V±10% 50Hz | |||||||

Main engine outline size | L 830 x W 730 x H375 mm | |||||||

Feeder outline size | L 235 x W 700 x H245 mm | |||||||

Net weight | 56 kg | |||||||

Gross weight | 83 kg | |||||||

ZB3245TSS

About the applicable element.

The minimal applicable element is 0402

The maximum applicable element is BGA100.

How about other style? How about the 0201?

Please feel free to contact me.

Main Feature

1. Closed-loop control, Step servo motor with the professional flexible.2. Pcb size: Max: 320x450mm (without tray). 320x250 (put tray).

3. The smallest component can be attached 0402. The largest: 20x20mm.

4. Industrial control computer: Install WIN7 system, the operation is simpler, can be networked, support remote assistance debugging.

5. Independent research and development system.

6. 27 kinds of plated materials.

7. S deceleration, performance as same as general servo motor.

8. With HD CCD Camera, accuracy and quick.

9. With 2 pick and place heads, types of high-precision nozzles, compatibility as Juki.

Product Photograph

About Us

FAQ

1).Q: How many nozzles do you supply? Do you sell nozzles and spares?

A: If the machine has two nozzle-heads, we supply 4 nozzles. If has four nozzle-heads, we supply eight nozzles. Yes, we do sell nozzles and spares. If you need any spars, just let us know.

2).Q: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

3).Q: How is the training?

A: After buying our machines, your engineers can go to our company or our engineers go to your factory if require, and we will train them how to use these machines.

4).Q: Is it hard to use these machines?

A: No, not hard at all. For our previous clients, at most 2 days is enough to learn to operate the machines.

5).Q: Does you machines have quality certificate?

A: All of our machines have passed CE certificate, ISO14001(BCC), ISO9001(IQNET) and have own patent.

6).Q: How about the warranty?

A: We support one year warranty( The nozzle with a warranty of 1 months; belt with a warranty of 3 months ). We will regularly update the software for customers. If there is any doubt in the process of operating the machine, pls feel free contact us. We will help you in time.

A: If the machine has two nozzle-heads, we supply 4 nozzles. If has four nozzle-heads, we supply eight nozzles. Yes, we do sell nozzles and spares. If you need any spars, just let us know.

2).Q: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

3).Q: How is the training?

A: After buying our machines, your engineers can go to our company or our engineers go to your factory if require, and we will train them how to use these machines.

4).Q: Is it hard to use these machines?

A: No, not hard at all. For our previous clients, at most 2 days is enough to learn to operate the machines.

5).Q: Does you machines have quality certificate?

A: All of our machines have passed CE certificate, ISO14001(BCC), ISO9001(IQNET) and have own patent.

6).Q: How about the warranty?

A: We support one year warranty( The nozzle with a warranty of 1 months; belt with a warranty of 3 months ). We will regularly update the software for customers. If there is any doubt in the process of operating the machine, pls feel free contact us. We will help you in time.

All the spare parts will be provided free of charge for you within the warranty period.

VIEW MORE

You may like

-

PCB board packaging vacuum packaging machine is simple to operate and simple to maintain.

-

Multifunctional Universal LED Bulb Assembly Equipment Fully Automatic LED Bulb Making Machine

-

Customized LCD Machine Accessories Glass Rod Quartz Rod

-

Magnetic powder brake

-

SE Series Arise actuators with various thrusts and shocks

-

Mobile Phone Jack Vacuum Coating Back Cover Film Envelope Machine for iPhone SAMSUNG Huawei Honor

-

Mobile phone hydrophobic nano liquid spraying machine

-

Pcb Drill Routing Cnc Machine Pcb Separator Cutting Machine Split Circuit Board Machine

-

85 inch Lcd Led Laptop Laser Screen Panel Repair Machine Laser Welding Solder Repair Machinery Bright Line Laser Repair

-

LED bulb machine light source board glue machine LED bulb machine electrical equipment

Other Products

-

$170.00 / set

$170.00 / set -

$369.00 - $389.00 / set

$369.00 - $389.00 / set -

$3950.00 - $4050.00 / set

$3950.00 - $4050.00 / set -

$3465.00 - $3645.00 / set

$3465.00 - $3645.00 / set -

$5000.00 / set

$5000.00 / set -

Electronic Components Making Automatic Pcb Benchtop Low Cost Desktop Mini Smt Pick And Place Machine$4050.00 / piece

Electronic Components Making Automatic Pcb Benchtop Low Cost Desktop Mini Smt Pick And Place Machine$4050.00 / piece -

$3080.00 / piece

$3080.00 / piece -

$1950.00 / set

$1950.00 / set