Rebar screw Thread rolling machine price

-

Supplier: Xingtai Judu Technology Co., Ltd. -

Region: Hebei, China -

Contact: Ms Mary Wang -

Price: $4980.00 /set -

Min. Order: 1 set

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Machinery Test Report: | Provided; |

| Main axis transmission power: | 5.5kw; | Place of Origin: | Hebei China; |

| Brand Name: | greatcity; | Application: | rolling thread; |

| Package Preview: | ; | Marketing Type: | New Product 2020; |

| Weight: | 2000kg; | Condition: | New; |

| Power: | 7.5kw; | Key Selling Points: | Competitive Price; |

| Warranty: | 2 years; | Local Service Location: | None; |

| Minimum diameter: | 3mm; | Applicable Industries: | Building Material Shops,Construction works ; |

| Showroom Location: | None; | Hydraulic transmission power: | 2.2kw; |

| Voltage: | 380v; | Selling Units: | Single item; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Dimension(L*W*H): | 155cm*155cm*145cm; |

| Warranty of core components: | 1 Year; | Certification: | CE; |

| Video outgoing-inspection: | Provided; | Core Components: | PLC,Motor; |

| Maximum diameter: | 56mm; | Packaging Detail: | drywall screw making machine in standard export wooden case; |

| Single gross weight: | 2000.0 KG; | Single package size: | 155X155X145 cm; |

| Production Capacity: | 3m/min; |

Rebar screw Thread rolling machine price

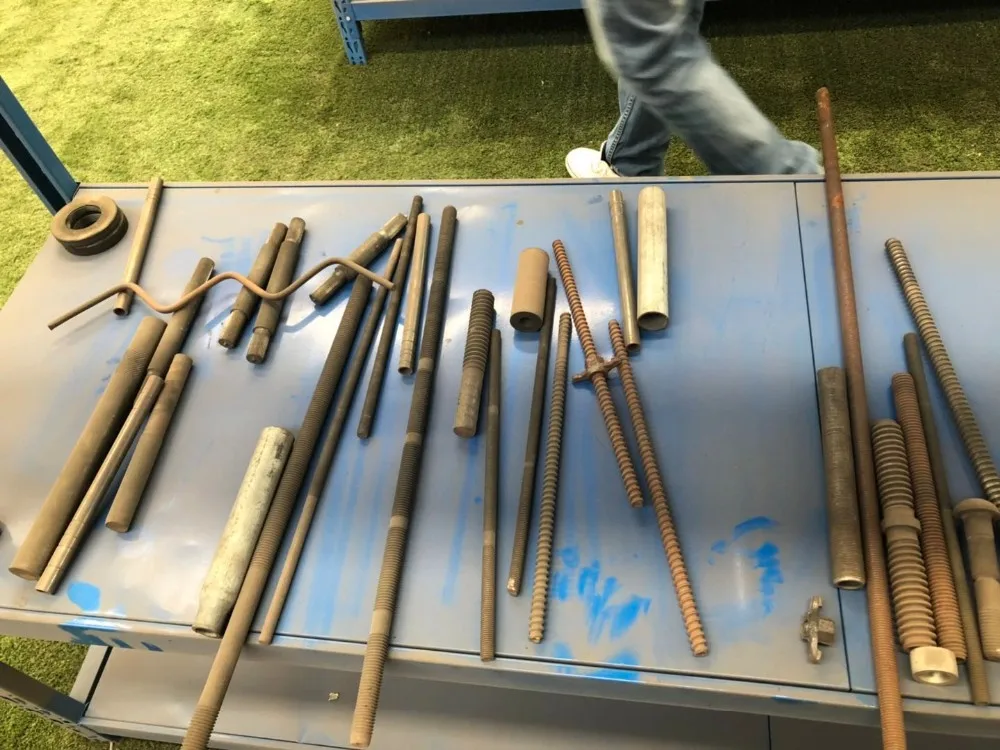

Product Application

rebar screw thread rolling machine is divided into two axis rolling machine and three axis thread rolling machine

1, two axis wire rolling machine has very strong superiority in hardware building, automobile and motorcycle fittings, traffic power, standard parts.

2, three axis rolling machine is triangle support in the pipe thread processing industry, true fidelity roundness, concentricity and perpendicularity

It is a multifunctional cold extrusion rolling thread machine, the workpiece in the cold rolling pressure range can be made to straight lines, twill, spur, helical and bevel gear spline rolling; straightening, necking, rolling light and various rolling forming. The machine has safe and reliable electric liquid control system and implementation, which can make each work cycle in manual, semi-automatic and automatic selection in three ways. The cold rolling is an advanced non cutting process, which can effectively improve the internal and surface quality of workpiece, the radial compressive stress produced during processing, and can significantly improve the fatigue strength and torsion strength of the workpiece. It is an ideal process with high efficiency, energy saving and low consumption.

The rebar screw thread rolling machine can equipped the auto feeding and loading machine. pls inquiry for details.

Model | Z28-150 |

Biggest rolling dia | 56mm |

Min rolling dia | 5mm |

Main power | 5.5kw |

Hydraulic power | 2.2kw |

Dimensions | 1550*1550*1450mm |

Weight | 2000kg |

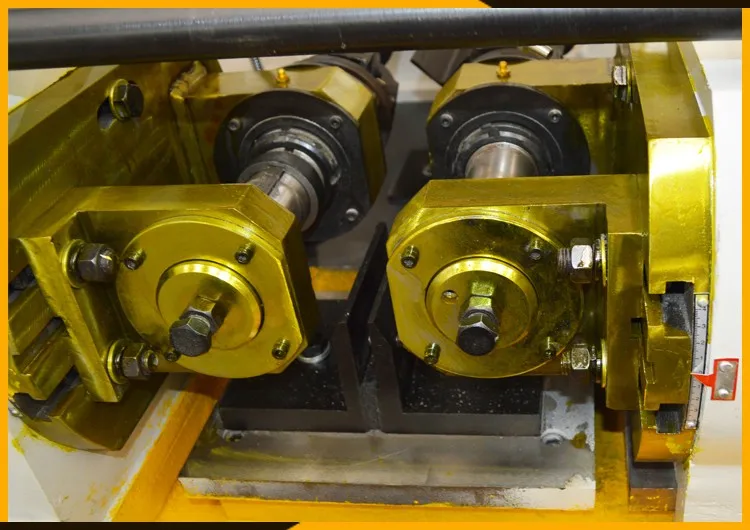

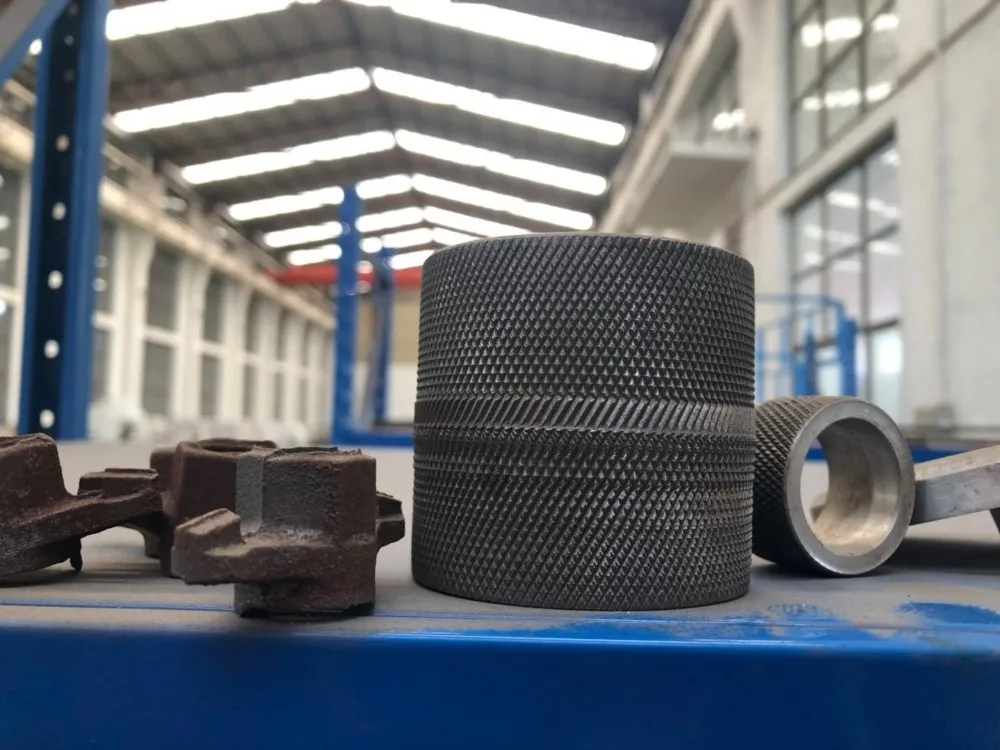

Machine Parts

Name: Thread roller

Brand: GREATCITY

Original: China

Main Features

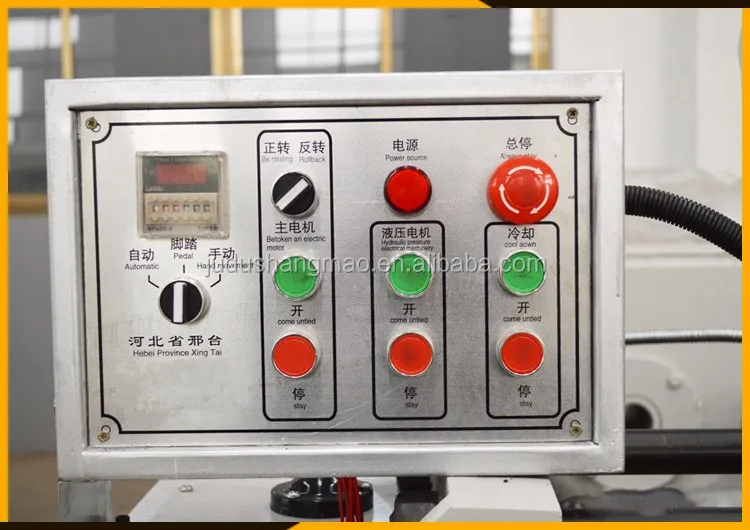

Name: Control Panel

Brand: GREATCITY

Original: China

make english type for you

Working principle of rebar screw thread rolling machine:

L and R are two pairs of involute rolling wheels with the same parameters, which are installed on two spindles of the rebar thread rolling machines, and can rotate synchronously under the drive of the transmission mechanism.The R wheel can be driven by the oil cylinder for radial feed motion, and the L wheel can be adjusted by adjusting the mechanism to coincide with the indentation of the R wheel on the surface of the workpiece P. The P locate the two center hole clamping, the adjustment fixture can make the axial movement in the force around the fixture O and spindle parallel to the axis of an angle, to ensure that the workpiece in the cold rolling process and keep two rolling wheels to roll in the free state, and convenient clamping the workpiece. The structure size, geometrical tolerance and technical requirements of the rolling wheel are formulated according to the rolling wheel and cylindrical measuring gear. The length of the normal line or the cross bar distance of the rolling wheel M is calculated according to the spline data of the gear, and the required material can be Cr12MoV (hardness 59 ~ 62HRC)

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging | ||

Size | 1.6 (L) * 1.6 (W) * 1.5(D) | |

Weight | 2 T | |

Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

1. Do you have any warranty?

Yes, we have. Two years warranty on host machine is given. Six months free replacement warranty for spare parts.

2. How is your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

3. What certification of rebar screw thread rolling machine do you have?

All of our machines have the CE certification which ensures the quality and safety. Our machines are under strict quality management to ensure good quality. Because we fully understand that it will be a great trouble if machine have any problem during working at oversea.

4. Will you teach how to use the drywall screw making machine?

Yes, we can provide a complete user manual and usage video for instruction and application. And 24/7 online consultant service ensure you whatever problem and whenever you meet, you can solve easily. It is easy to operate by anyone with the instructions.

5. How about the shipment?

The machine will be shipped within 2-3 days after the receipt of your payment.

6. Can visit your factory?

Welcome to our factory. We would like to make invitation letter for you. Hope we can cooperate with you for a long term.

Xingtai Judu Technology Co.,Ltd is located in the historical industrial zone, Hebei province. Founded in 1999, we are a professional manufacturer of series of CNC stirrup bending machine and rebar screw thread rolling machine. For twenty years in development, our company has always been adhering to credit the first best quality in after sale service, innovation, self-improvement, adhere an independent intellectual property right as the core of scientific and technological innovation. The current steel hoop bending machine and horizontal lathes for the company's main product are sold throughout the country, some products exported to Asia, Africa, and other countries and regions, we are abide by integrity and innovation, entrepreneurial spirit, relying on leading research and development capabilities efficient manufacturing, stable quality and good service to meet the needs of our customers at home and abroad, the company has now passed the ISO9001:2000 international quality management system certification.

"Greatcity" trademark has been identified as an unique brand name product that got the honorary title among many.

Within more than 20 years of development besides struggles, GreatCity is still keeping up its effort to maintain a brilliant business success in whole over the world due to its hardworking, courage and the will to improve its creation for customer satisfaction and maintain the reputation to be the best Chinese machinery manufacturer.

Sales Manager Ms Kitty liu

Skype: greatcity77

Mobile / whatsapp / wechat : 008615512868421

QQ: 694679222

Email: kitty@greatcitygroup.com

-

-

Affordable automatic hydraulic thread rolling machine with gear motor and main components

-

High-strength thread rolling wheel steel bar thread rolling machine wheel three rollers

-

High Quality Thread Rolling Machine Self Drilling Self Tapping Screw Machine

-

High-speed automatic self-tapping screw machine cold heading machine

-

4-42mm Thread Rolling Machine Bar Rod Thread Rolling Machine from China Manufacturer

-

Screw Machine Price Automatic/Machine Production Screws

-

Customized high-speed and stable automatic thread rolling machine to manufacture screws

-

Keruien steel bar thread rolling machine with round tooth roller die roller

-

Hot selling high quality thread rolling machine for factory

Other Products

-

$14999.00 / set

$14999.00 / set -

$3380.00 - $3580.00 / set

$3380.00 - $3580.00 / set -

$5700.66 / set

$5700.66 / set