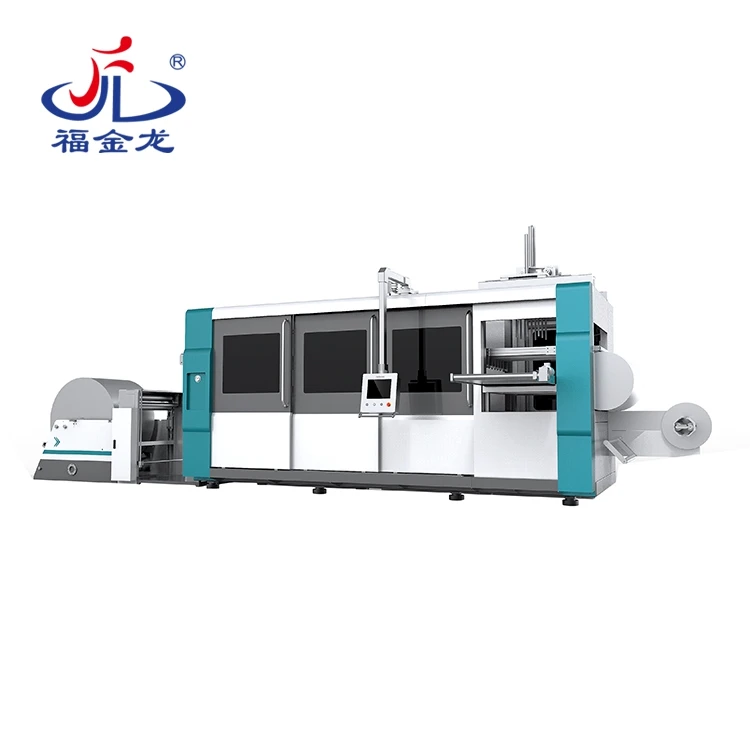

Fully Automatic Paper Cup lid Forming Machine Plastic lid Thermoforming Machine

-

Supplier: Zhejiang Fuxinlong Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Linda Lin -

Price: $30000.00 /set -

Min. Order: 1 set

Product details

| Warranty of core components: | 1 Year; | Local Service Location: | None; |

| Video outgoing-inspection: | Provided; | Supply Ability: | 10 Set/Sets per Month; |

| Air Comsumption(L/min): | 25; | Application: | Plastic Products; |

| Power supply: | Made according to customers' requirements; | Warranty: | Within one year; |

| Place of Origin: | Zhejiang China; | Heating Power (kW): | 55; |

| Forming Width (mm): | 660; | Water Comsumption(L/min): | 100; |

| Product Type: | Plastic Cup; | Applicable Industries: | Hotels,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Food & Beverage Shops,Advertising Company; |

| Core Components: | PLC,Motor; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Certification: | ce; | Max.Forming Height(mm): | 100; |

| Machinery Test Report: | Provided; | Packaging Detail: | Wooden case with plastic film; |

| Sheet Thickness(mm): | 0.1 - 2 mm; | Package Preview: | ; |

| Weight (T): | 7; | Forming Length (mm): | 350; |

| Showroom Location: | None; | Brand Name: | Fujinlong; |

| Dimension(L*W*H): | 9000x2200x2500(mm)(L*W*H); | Marketing Type: | New Product 2020; |

| Air Pressure(MPa): | 0.7; | Condition: | New; |

| Weight: | 7T; | Power(W): | 55KW; |

| Processing Type: | Plastic Thermoforming Machine; | Voltage: | 380V/50HZ; |

| Plastic Type: | Hips,PVC,PS,PP,EPS,PET; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Key Selling Points: | Easy to Operate; |

| Port: | NINGBO; |

Fully Automatic Paper Cup lid Forming Machine Plastic lid Thermoforming Machine

Video:

https://youtu.be/Y54kaBucGYI

Product Description

Usage

This series mainly used for making different kinds of plastic flower

pots, trays, cups and other plastic packaging products.

Major Construction Featurus

The operation is controlled by PLC with touch screen.

Adopt four pillars to fix the mould.

Fill oil automatically to lubricate mechanism movement at certain time.

Temperature control modules to control each temperature area.

Machine production process started from sheet feeding, heating, stretching, forming, in-mould

cutting (and in-mould holing) in one stroke.

Convenient operation, outstanding performance, low noise and high quality.

| Model | FSDT-660/350-A | FSDT-660/350-B |

| Quantity of Stations | 3 | 4 |

| Sheet Material | PP,PS,PVC,PET,HIPS,EPS,OPS,ABS | |

| Max.Forming Area | 660*350mm | |

| Max.Pos/Neg Depth | 100/30mm | |

| Max.Plastic Sheet Width | 690mm | |

| Max.Plastic Sheet Dia | 800mm 500KG | |

| Thickness of Plastic Sheet | 0.1-2mm | |

| Max.No-Load Speed | 30Cycles/min | |

| Air Consumption | 1.5-1.8m3/min,0.5-0.8Mpa | |

| Overall Power | 55KW | 60KW |

| Dimension | L9000*W2200*H2500mm | L9800*W2200*H2500mm |

| Weight | 7T | 8T |

| Power Supply | 380v/50Hz Three Phase Four Wires | |

Packaging & Shipping

You Can Send Your Message To Us >>

Company Information

Samples:

You Can Send Your Message To Us >>

Contact us

You Can Send Your Message To Us >>

VIEW MORE

You may like

-

2024 new plastic cup making machine price of plastic cup making machine

-

Plastic PP Container Vacuum Forming Machine Thermoforming Machine Plastic Sheet German Vacuum Pump (100m3/h) Popular Products 2023 100

-

Fully automatic takeout disposable food container PS foam Thermocol lunch box machine foam tableware production line

-

PS Disposable Food Container Thermocol Platesetter

-

High speed plastic bottle cap molding machine

-

Used Small High Speed Automatic Plastic Cap Thermoforming Machine Cylindrical Cap Vacuum Forming Machine

-

Machine Melamine Cutlery Set Cutlery Machine blow molding

-

Hot Sale Old Thermoforming Machine Food Container Disposable Plastic Tray/Cup

-

Disposable Cup Automatic Plastic Cup Thermoforming Machine

-

Disposable Plastic Glass Machine

Related Search

automatic plastic cup lid thermoforming machine cost

paper cup lid making machine

automatic paper cup making machine price

factory price automatic paper cup coaster machine

paper cup high speed machine

paper cup flex printed machine

paper cup flow packing machine

automatic paper box printing slotting machine

automatic plastic forming machine suppliers

paper cup forming machine