Tire Recapping Machines for tyre retreading process

-

Supplier: Rizhao Melion Industry Co., Ltd. -

Region: Shandong, China -

Contact: Mr Joe Yan -

Price: $50000.00 /set -

Min. Order: 1 set

| Weight (KG): | 5800; | Condition: | New; |

| Marketing Type: | Hot Product 2021; | Warranty: | 2 years; |

| Voltage: | 380v; | Supply Ability: | 100 Set/Sets per Month tire recapping machine; |

| Payment Terms: | Western Union,T/T; | Power (kW): | 98; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Brand Name: | MELION; |

| Local Service Location: | None; | Key Selling Points: | Multifunctional; |

| Port: | Qingdao; | Showroom Location: | None; |

| Control: | Auto; | Core Components: | PLC,Pressure vessel; |

| Video outgoing-inspection: | Provided; | Heating way: | Electrical; |

| Standard Chuck Rim: | 15"-20"; | Applicable Industries: | Tire Machinery; |

| Function: | recap used truck tires; | Air Supply: | 0.6-0.8 Bar; |

| Training: | yes; | Place of Origin: | China; |

| Machinery Test Report: | Provided; | After-sales Service Provided: | Engineers available to service machinery overseas,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Technology: | Melion Precure Retread (Cold); | Description: | tire recapping machines; |

| Optional Heating: | Steam,Oil Heating; | Warranty of core components: | 2 years; |

| Packaging Detail: | suitable for long time transport by ship; |

Tire Recapping Machines for used Truck Bus Tyre Retread

Melion Retreading Technology:

Precure or "Cold" tire recapping involves vulcanization without a mould at a temperature of between 95 °C and 117 °C. The tyre is put together using a pre-vulcanized Tread Liner Rubber (= new tread) and a non-vulcanized Bonding Gum(Cushion Gum) layer. The bond between the carcass, the bonding gum and the precured tread is created in an autoclave(Curing Chamber). Precure retreading has become fully established in the truck tyres sector since the introduction of radial tyres in the mid-1960s.

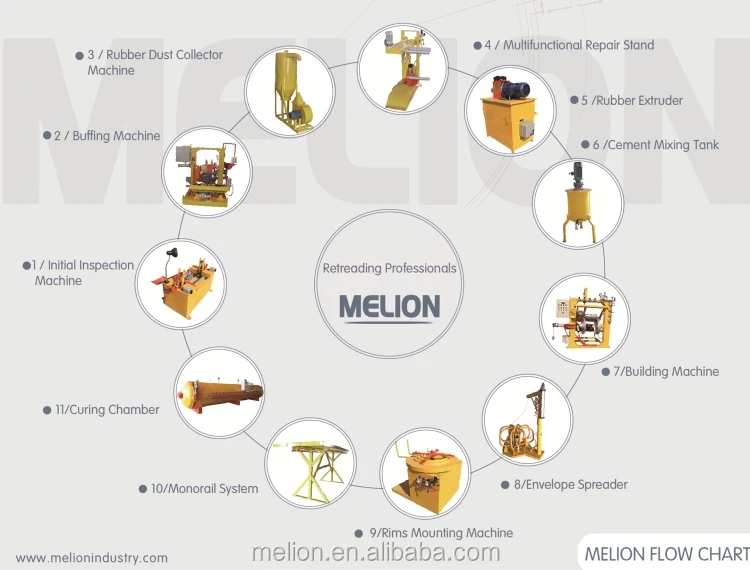

Tire Recapping Machines/Tire Retreading Machines complete set

Initial Inspection Machine,Buffing Machine,Dust Collector, Multi-functional Repair Stand, Extruder Machine, Cement Mixing Tank, Building Machine,Envelope Spreader,Rims Mounting Machine,Monorail,Curing Chamber,Pressure Test Machine etc.

Melion Precure Tire Retreading Equipment Process

1. Collection of Casings

Worn tyres are collected to select suitable casings for tyre retread.

2. Initial Inspection

Each tyre received in a retread plant is subjected to a rigorous visual inspection. Inspectors are assisted by the use of non-destructive sophisticated MELION inspection machine.

3. Buffing After inspection

The tyre's old tread is mechanically removed on high speed buffers. MELION's buffers are extremely accurate and will remove the proper amount of old rubber while turning the tyre to an exact specified diameter and radius.

4. Section Repairs & Skiving

With advances in state-of-the-art repair materials and repair methods, many of these tyres can be routinely repaired and in most cases can be retreaded when the original tread is worn off. The repair station is where any surface injury is treated using effective material and tools for grinding and patching.

5. Cementing and Filling

Even in small injuries it is critical that the injury is cleaned and filled. If this is not done, severe rust, separation and steel cable looseness could take tyre out of service. The injury should be inspected, and then cleaned out with a carbide cutter. After cementing the injury, a vulcanizing rubber stem should be applied to "fill" the injury. This would create a permanent repair that maximizes tyre life.

With MELION designed-and-built spray booth, your cementing operation can be executed in a clean, efficient & environmentally responsible manner.

6. Building – Tread Rubber

In the pre-cure system, the tread rubber has already been vulcanized with the new tread pattern design. The buffed tyre needs a thin layer of cushion gum to be wrapped around its crown area. The pre-cured tread rubber is then applied with the building machine. This is called the building process.

7.a) Enveloping & Rim Mounting

The built tyres are then mounted with envelops and rims to prepare them for curing.

b) or Double Envelope System

For enveloping, tyres are first fitted an outer envelope at the envelope-mounting table before the inner envelope is fitted into them. The enveloped tyres are then vacuumed out for preparation prior to curing. Modern plants have their casings hoisted by monorail systems. With professional planning from MELION engineers, you can be assured of workstations designed to maximize output and ease workflow.

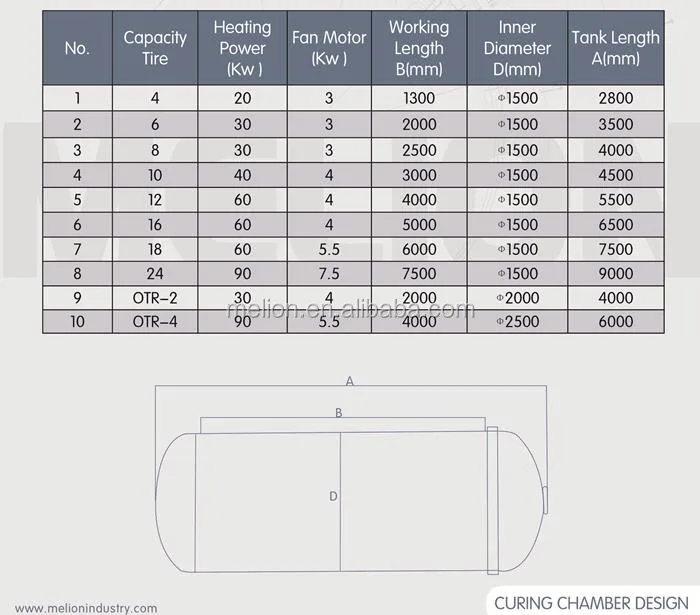

8. Curing by Chamber

The tyre is then placed in a curing chamber and the pre-cured tread becomes adhered to the tyre through a vulcanizing process.

Our wide engineering capabilities and experience enable MELION to build chambers to suit our clients' different preferences for size, steam heated, electric heated, or double heating system, semi-automatic and automatic chambers.

The monorail & hook system increases productivity by cutting down on chances of casings contamination and allows for faster loading and unloading of tyres. This increases your work place safety and productivity.

9. Final Inspection & Painting

The retreaded tyre is subjected to a final inspection. This inspection insures that only tyres that meet industry quality standards are allowed to leave the retread plant. All retreaded tyres are encouraged to be returned with the sidewalls painted using a light coat of black tyre paint.

We manufacture complete set of recapping tire machines with different production output from 4 to 24 tyres satisfying different buyer's requirement.Our engineers can go to buyer's factory for help installing and giving technical courses to the workers.With our quality rubber materials of Precured Tread Rubber ,Rubber Strip and Cushion Gum,you are guanranteed to produce quality products of retreaded tyres.

Rizhao Melion Industry Co., Ltd

As a tire retreading machines manufacturing supplier who providing Turn-Key Service,Melion provide customers with complete solutions all the time,including professional marketing planing,production line procedure analysis,suitable raw materials supply,free technical training and so on.

With its quality products and technical support ,Melion has widely gained excellent reputation from all customers from China and abroad.

A: Yes,we are complete tire retreading solutions supplier who can supply equipment,rubber materials,consumable tools from A to Z.

Q: How long is your delivery time?

A: Generally it is 45 days production time after receive deposit.

Q: Do you provide overseas installation and training service ?

A: Yes, we could send our engineers go to your country for installing and training services.

Q: Can I come to your factory for learning?

A: Welcome for visit any time!

If you have another question, pls feel free to contact us as below:

Sales(at)melionindustry.com

-

Low-price car tire retreading equipment/car tire retreading complete production line

-

Used tire retreading machine/tire retreading machine made in China

-

High quality rubber High quality rubber refill materials

-

Used Tire Retreading Machines Retreading Vehicles Renew Equipment at Low Prices

-

Refurbished machine

-

REENCAUCHADORA LLANTAS Tire Retreading Machine

-

Tire Vulcanizer Repair Electric Retreading Machine

-

Automatic Electric Heating Tyre Repair Machine Hot Tyre Retreading Vulcanizing Machine Customized 220V/380V 1500 KG CN;SHN Q345R

-

Rubber Extruder Gun for Tire retreading machine handheld

-

Used tire retreading machine / tire recycling machine / recycling machinery for waste tires

Other Products

-

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$800.00 / set

$800.00 / set -

$50000.00 / set

$50000.00 / set -

$9000.00 / set

$9000.00 / set