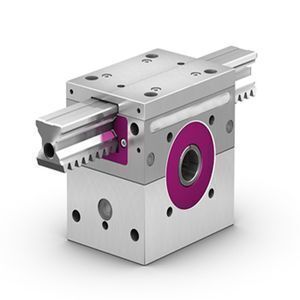

customized carbon steel liner rack gear drive for transmission system

-

Supplier: Dongguan Xiexu Hardware Products Limited -

Region: Guangdong, China -

Contact: Ms. Sara Yang -

Price: $2.00 / >=10 pieces -

Min. Order: 10 pieces

| Port: | shenzhen; | Showroom Location: | None; |

| delivery time: | 15-25 days; | Warranty: | 1.5 years; |

| Supply Ability: | 100000 Piece/Pieces per Month; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,paypal; |

| Brand Name: | HKAA; | Condition: | New; |

| color: | silver/black; | After Warranty Service: | Video technical support; |

| service: | OEM ODM; | Size: | customized; |

| surface treatment: | polish/anodizing/plated; | Standard or Nonstandard: | Nonstandard; |

| Processing: | Hobbing; | Model Number: | F-0047; |

| material: | brass/stainless steel/aluminum/steel; | Applicable Industries: | Hotels,Garment Shops,Manufacturing Plant,Machinery Repair Shops,Restaurant,Energy & Mining,Advertising Company; |

| shipping: | DHL, UPS, FEDEX, TNT, etc; | Place of Origin: | Guangdong China; |

| payment terms: | T/T, paypal, western union, etc; | Packaging Detail: | bubble packed individually then put in carton to prevent from damaging and scratches in transporting.; |

| Local Service Location: | None; | Material: | Steel; |

| Certification: | ISO9001:2008, TS16949, ISO13485, etc; | Product name: | rack gear drive; |

| Shape: | Rack Gear; |

customized carbon steel liner rack gear drive for transmission system

| Name: | rack gear drive | |

| Brand: | HKAA | |

| Testing machine: | hardness tester/pull and push force tester/HEXGON brand CMM from swiss | |

| Application: | transmission parts | |

| Color | black/silver/orange/yellow/red/purple/blue | |

| MOQ: | 10pcs | |

| Processing: | cnc milling parts /cnc turning parts /die casting parts /forging parts | |

| Material: | Mild steel/ 316 304 306 stainless steel/aluminum | |

| Tolerance: | 0.01mm | |

| Certificate: | ISO9001:2008 TS16949 | |

Specialty Hardware Manufactory!

Surface: customer requirement

Material: steel /stainless steel/ aluminum / brass / iron / zinc / alloy ,Any other material and dimension depends on customers' demand.

Usage: machinery / furniture / toy / woodboard / wall

Manufacturing process: casting parts

Euipment: casting machine

Testing equipment: projector

Tolerance:+/-0.05MM

We are willing to provide with sample for quality and function testing.

We are ISO 9001: 2008 certified firm.

HA AA was founded in 1998, covering an area of 11,000 square meters and 110 workers . 80% of our products are sold to oversea market such as Germany,UK,France, Italy,USA, Canada,Australia,Japan,South Korea etc. We are ISO 9001:2008,TS16949 certified company. Our products are widely used in medical,military,agriculture,marine,industry, hydraulic,auto,motorcycle,electron,optics,inst rument,communication,nuclear,chemical, Petrochemical,Energy,food industry etc.

Our machines:

50 CNC turning machines from Japan with FANUC system,

32 CNC milling machinee from Taiwan with Mitsubishi System,

10 stamping machines and 6 hobbing gear machines

1 Mazak machine

CMM from Hexagon

2.5 dimensional full automatic detection instrument

Projector

1 Concentricity tester

2 Roughness tester

3 Tensile tester

4 Salt spray tester

other basic inspect tooling like Calpers, Micrometer, Height gauge, Pin gauge, Thread gauge, Slot card and so on.

Inspection equipment:Our detecting instruments as:

Our Certifications

Industry Focus | Appliance/ Automotive/ Agricultural Electronics/ Industrial/ Marine Mining/ Hydraulics/ Valves Oil and Gas/ Electrical/ Construction |

Intended Application | Shafts Valve Components Automatic Door Components Cable/ Electronic Connector Fire Suppression System Components Fittings/ Fasteners Gears/ Hardware Roller Bearings |

Lead Times Available

| Max: 2 Weeks (On Initial Order) Rush Services Available |

Industry Standards | ISO 9001:2008 PPAP RoHS Compliant |

Additional Capabilities | CAD Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering |

Equipment List | From simple 2-axis turning to 7-axis, turn-mill-drill CNC Swiss-type machines, we are equipped with a full line of CNC equipment from the following manufactures: molding machines/ stamping machines automatic lathe machines/ spring machines. |

Automation Capabilities | Continuous Machining |

Material (Metals) | Alloy Steels/ Aluminum/ Brass/ Bronze Alloys Carbon Steel/ Copper/ Stainless Steel/ Tool Steel Cold Rolled Steel/ Bearing Steel |

Material (Plastic Polymers) | ABS/ Delrin/ Nylon/ PVC |

Processes (Special Capabilities) | Broaching/ Hobbing/ Slotting |

Tolerance | ±0.0002 in ±0.0051 mm

|

Packaging

Shipping

1. We are willing to provide with sample for quality and function testing.

Q1:How to guarantee the Quality of Industrial Parts?

A1:we are ISO 9001-2008 certified firm. we have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2:What's the Advantage of Your Parts for Industry Products?

A2:Our advantage is the competitive prices, fast delivery and high quality. Our employees are responsible-oriented, friendly-oriented,and dilient-oriented. our Industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3:what are our machining equipmengts?

A3:Our machining equipments include CNC milling machines, CNC turning machines, stamping

machines,hobbing machines, automatic lathe machines, tapping machines, grinding machines,

screw machines, cutting machines and so on.

Q4: What shipping ways our use?

A4:Generally speaking, we will use UPS or DHL to ship the products. Our customers can reach the

products within 3 days.

If our customers do not need them urgently, we will also use Fedex and TNT.

If the products are of heavy weight and large volumn, we will ship them by sea. This way can save

our customers a lot of money.

Q5:Who are our main customers?

A5:HP, Samsung, Jabil Group,Lexmark,Flextronic Group.

Q6:What materials can you handle?

A6:Brass,bronze,copper,stainless steel, steel,aluminum,titanium And plastic.

Q7:How Long is the Delivery for Your Industrial Part?

A7:Generally speaking, it will take us 15 working days for machining parts and 25 working days for

the for stamping parts products. But we will shorten our lead time according to customers' demands

if we are able to.

-

0414.2023-1.75M-36Z Audis custom ground spur gear

-

Professional custom offset Frony sprocket pinion Primery transmission gear

-

European Standard M1 M2 M3 M4 M5 M6 Custom CNC Machining Steel Helical Gear Rack and Pinion M1.25

-

M4 tooth metal steel rack for automatic sliding door

-

Spur gear rack and pinion M1*15*15*1500mm

-

Famous Taiwan YYC rack and pinion

-

Garage Door Opener Gear and Gear Shift Kit

-

Nylon Pinion CNC Rack and Pinion Plastic Circular Helical Gear Rack

-

Casement door rack and gear set

-

22mm thickness size sliding rack automatic door rack 22*22*1005m

Other Products

-

$1.00 / piece

$1.00 / piece -

$0.20 / piece

$0.20 / piece -

$0.90 / piece

$0.90 / piece -

$120.00 / piece

$120.00 / piece -

$2.00 / piece

$2.00 / piece -

$1.00 / piece

$1.00 / piece -

$1.00 / piece

$1.00 / piece -

$0.90 / piece

$0.90 / piece