Spur gear rack and pinion M1*15*15*1500mm

-

Supplier: Tianjin Haorongshengye Electrical Equipment Co., Ltd. -

Region: Tianjin, China -

Contact: Ms Anna Zhang -

Price: $0.20 /piece -

Min. Order: 1 piece

Product details

| length: | 1000mm | Health status: | new |

| Standard or non-standard: | standard | Origin: | Tianjing, China |

| Mechanical test report: | if | Packaging Details: | According to our customer's request |

| brand: | HRSY | accurate: | DIN7 |

| usage: | CNC machine tool | payment terms: | L/C, Western Union, T/T, MoneyGram |

| port: | Shanghai/Tianjin/Dalian/ | Warranty: | 6 months |

| width: | 15mm | Core components: | gear, rack |

| Marketing Type: | 2019 Hot Products | module: | 1 |

| Video shipment inspection: | if | Core component warranty: | 6 months |

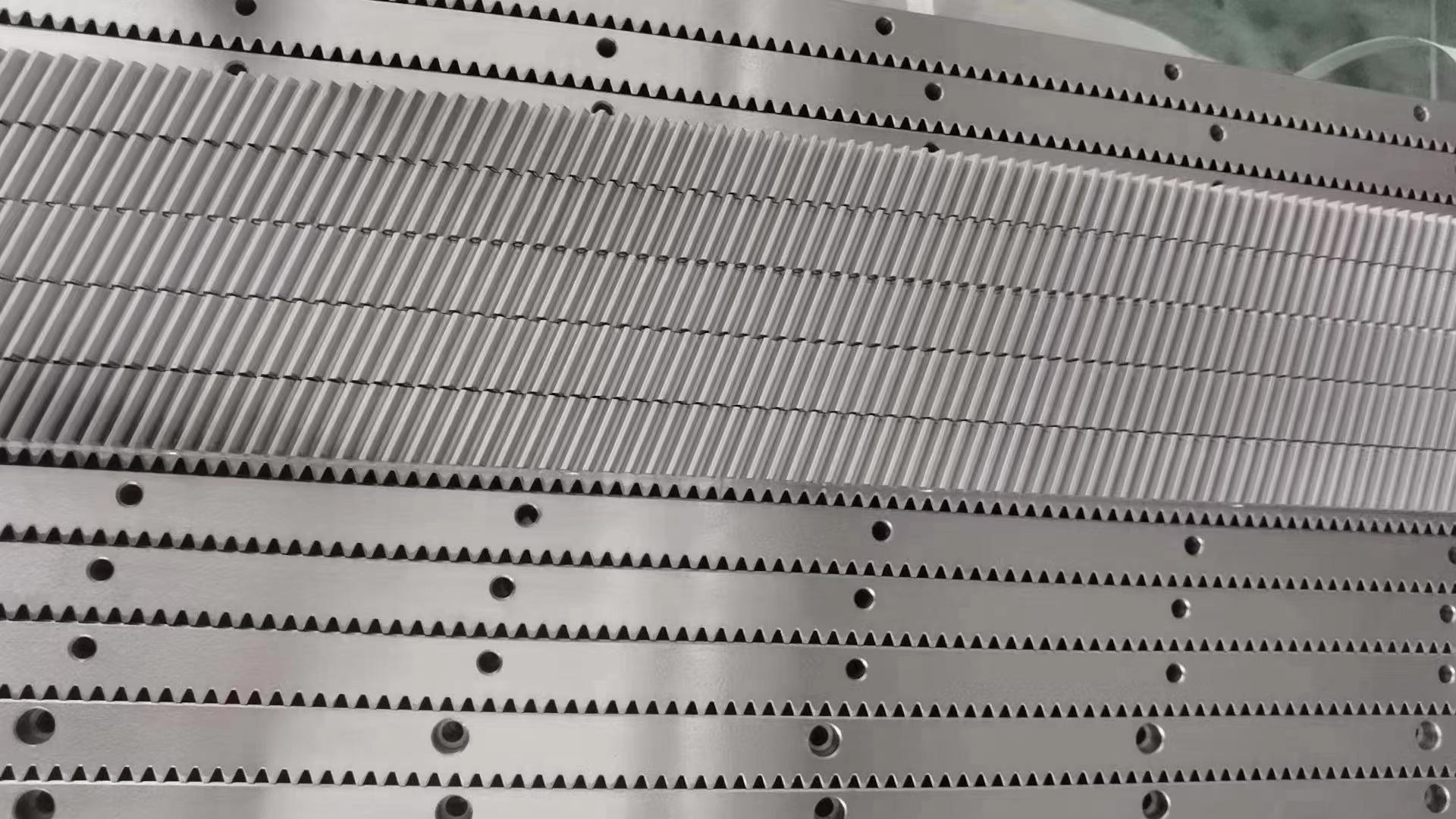

| Material: | Steel C45, Brass, Plastic, Stainless Steel 316, 304,, Steel | Tooth profile: | straight teeth |

| Showroom location: | not any | Weight (kg): | 2 |

| Applicable industries: | Building material stores, manufacturing plants, machinery repair shops, food and beverage plants, farms, retail, construction | Supply capacity: | 10,000 specific discussions per week |

| shape: | rack | model: | M1*15*15*1500mm |

| high: | 15mm | color: | Black |

| Processing: | Hobbing | Surface treatment: | Oxide |

rack

product | rack | ||||||

Accuracy class | DIN5, DIN6, DIN7, DIN8, DIN10 | ||||||

Material | C45 Steel, 304SS, 316SS, 40CrMo, Nylon, POM | ||||||

heat treatment | High Frequency, Quenching/Carburizing, Tooth Hardening | ||||||

surface treatment | Zinc plated, nickel plated, chrome plated, black oxide or as your need | ||||||

application machine | Precision cutting machine. lathe milling machine grinder Automated mechanical system Automated storage system. | ||||||

production machine | CNC engine lathe CNC milling machine CNC drilling machine CNC grinder CNC cutting machine Machining Center | ||||||

Way of working | Action speaks louder than words. | ||||||

Rack type | Specification | color |

Helical rack and pinion | M1 15*15*1000mm | white |

M1.5 19*19*1000mm | white | |

Helical rack and pinion | M2 24*24*1000mm | white |

M3 29*29*1000mm | white | |

M4 39x39x1000mm | white | |

Spur gear harrow | M1 15*15*1000mm | Black |

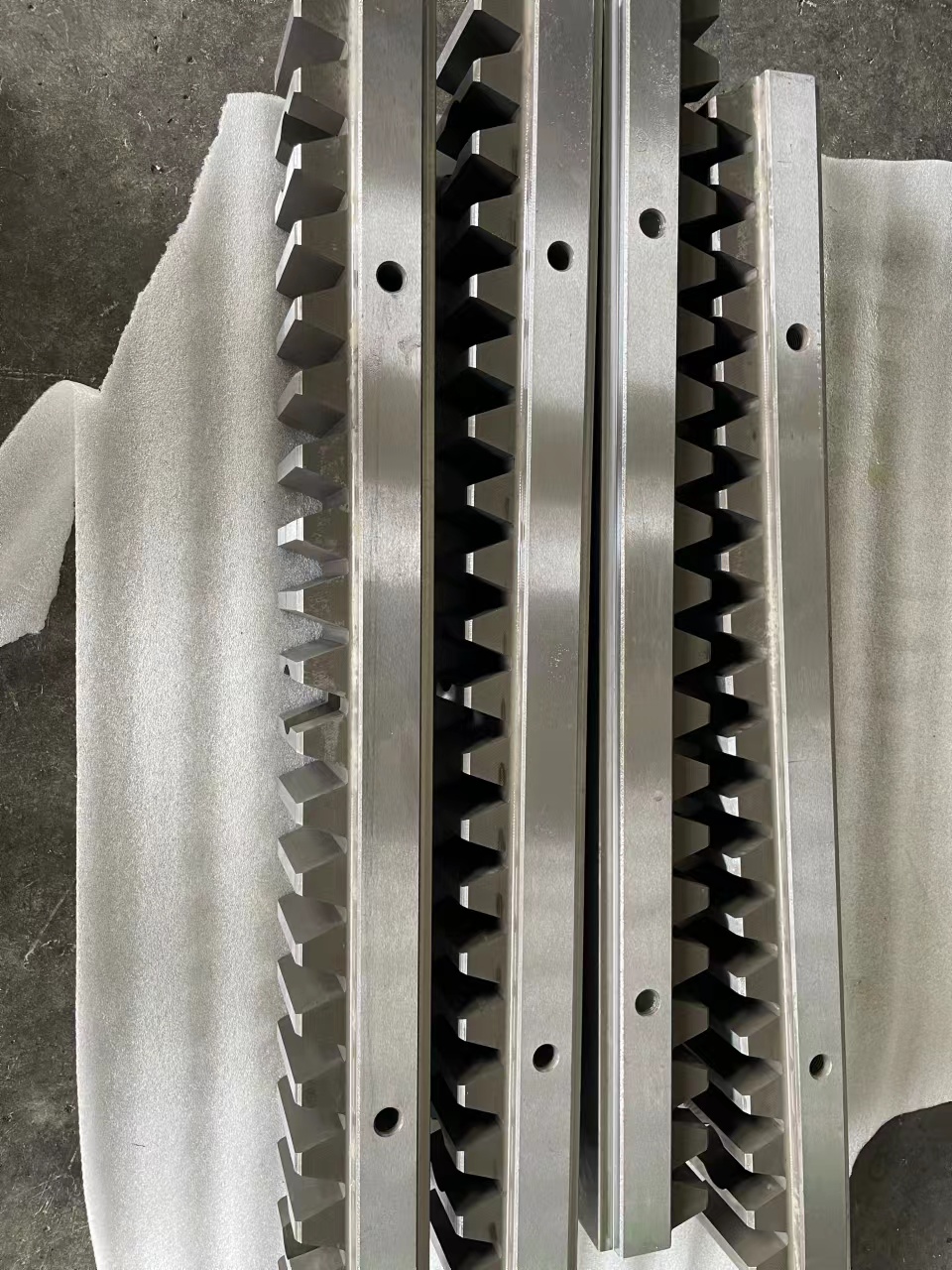

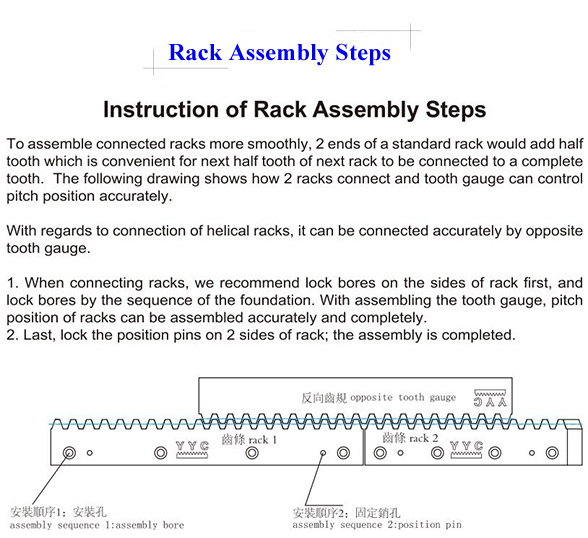

rack assembly

In order to assemble the connecting rack more smoothly, half teeth will be added at both ends of the standard rack, so that the lower half teeth of the next rack can be connected into a complete tooth. The picture below shows how the 2 racks are connected and how the tooth gauge precisely controls the pitch position.

For the connection of the helical rack, it can be connected accurately through the tooth gauge.

1. When connecting the rack, it is recommended to drill the locking holes on both sides of the rack first, and lock the holes in the basic order. By assembling the tooth gauge, the pitch position of the rack can be assembled accurately and completely.

2. Finally, lock the positioning pins on both sides of the frame; the assembly is complete.

For the connection of the helical rack, it can be connected accurately through the tooth gauge.

1. When connecting the rack, it is recommended to drill the locking holes on both sides of the rack first, and lock the holes in the basic order. By assembling the tooth gauge, the pitch position of the rack can be assembled accurately and completely.

2. Finally, lock the positioning pins on both sides of the frame; the assembly is complete.

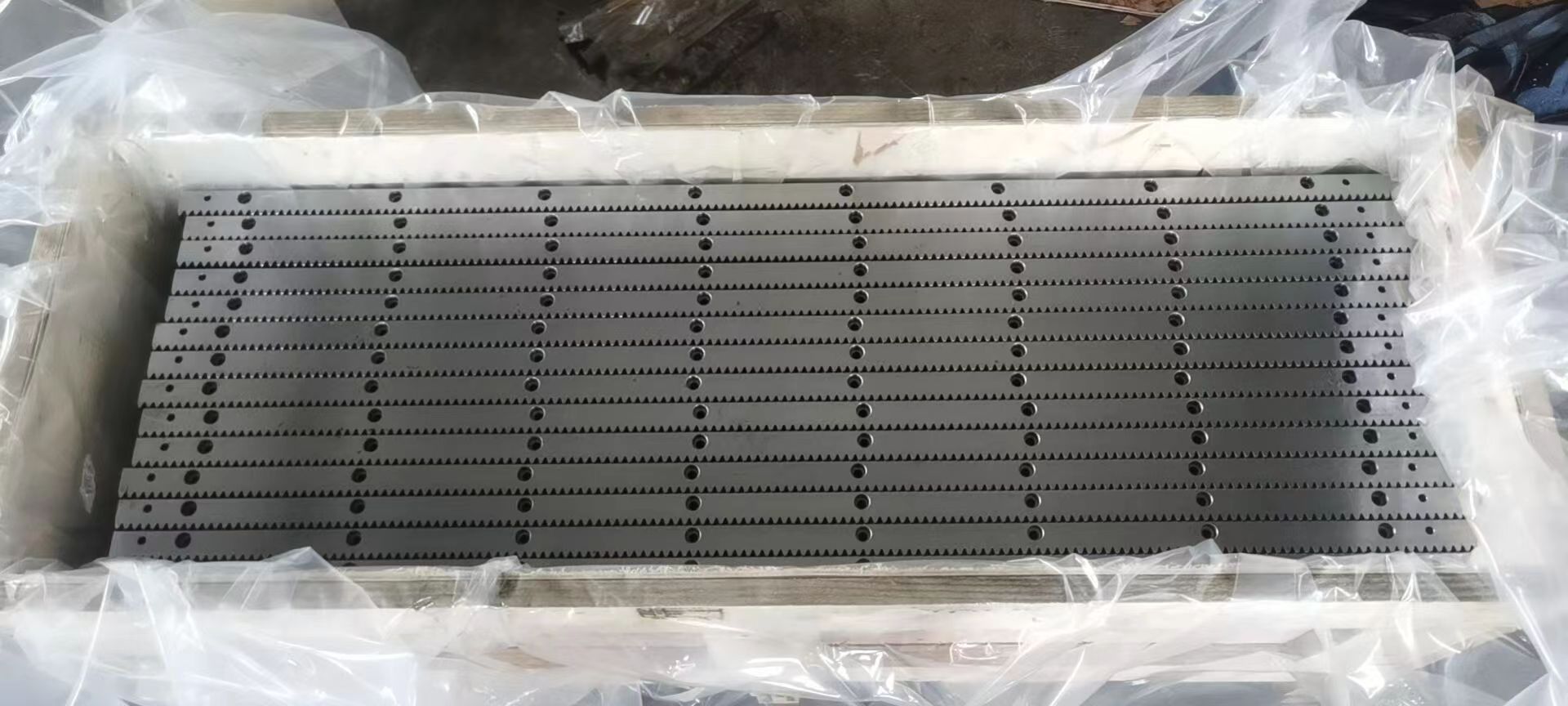

pack

Small quantity: we will use carton.

Large quantity: We will use wooden boxes.

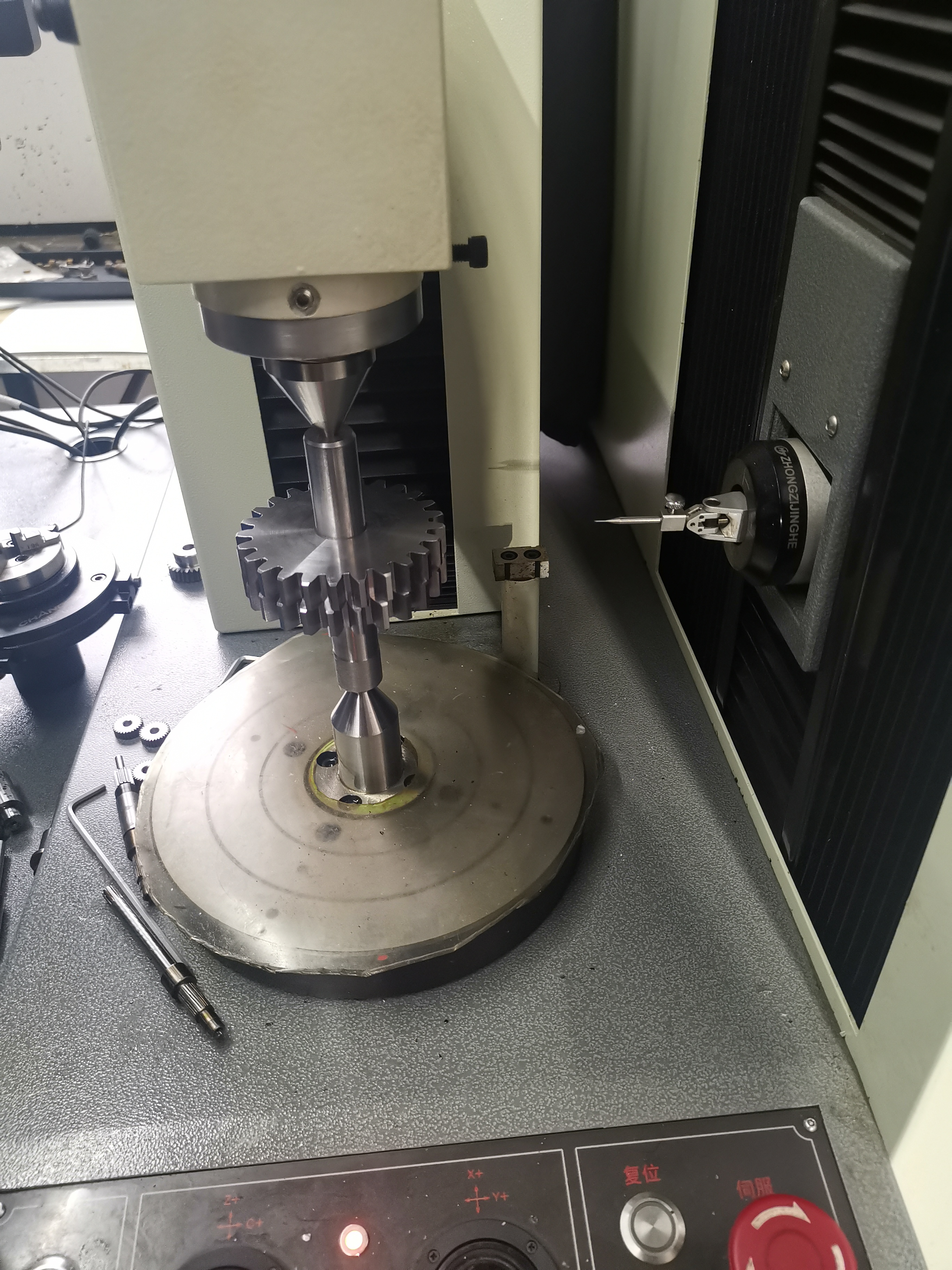

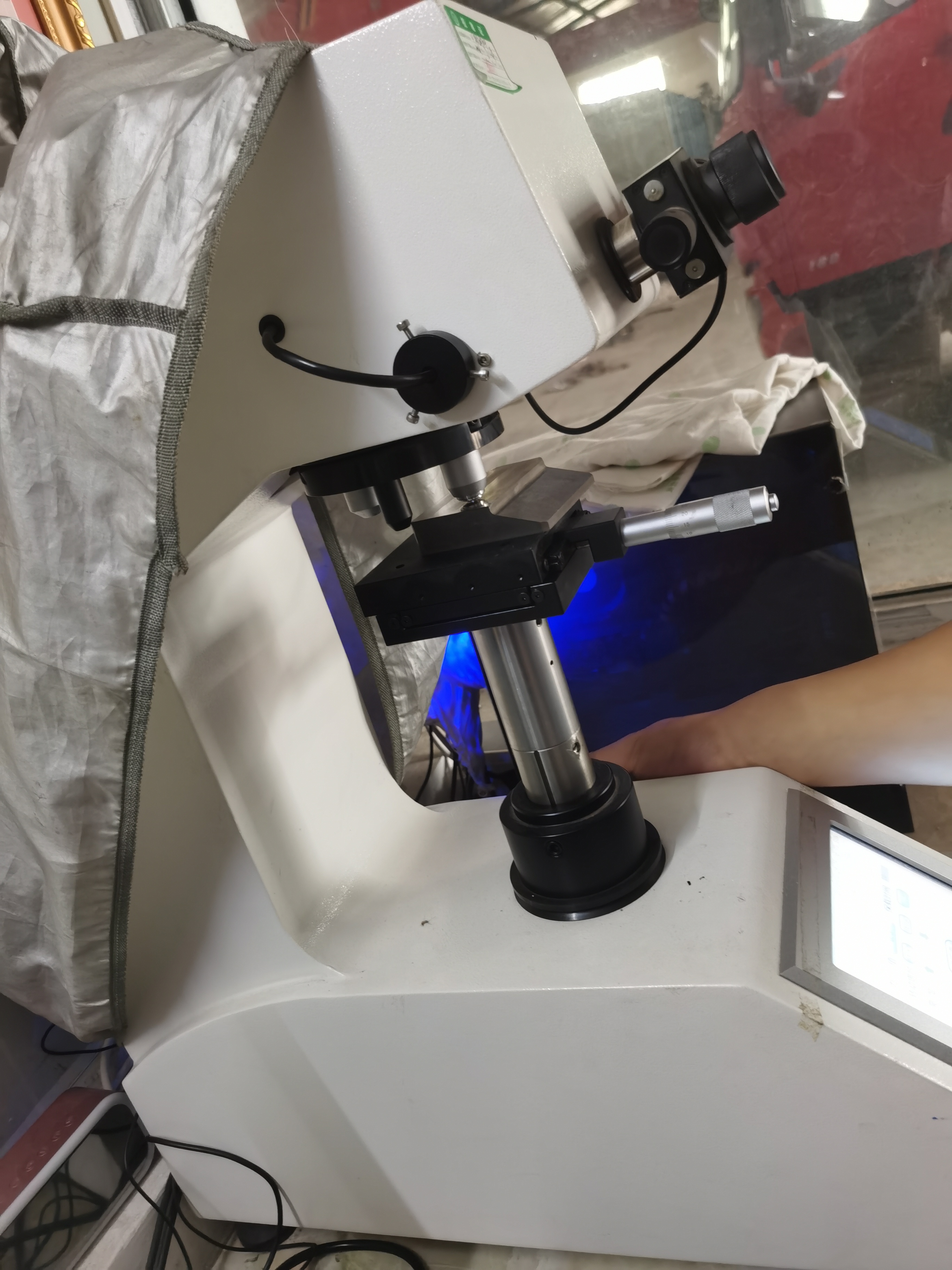

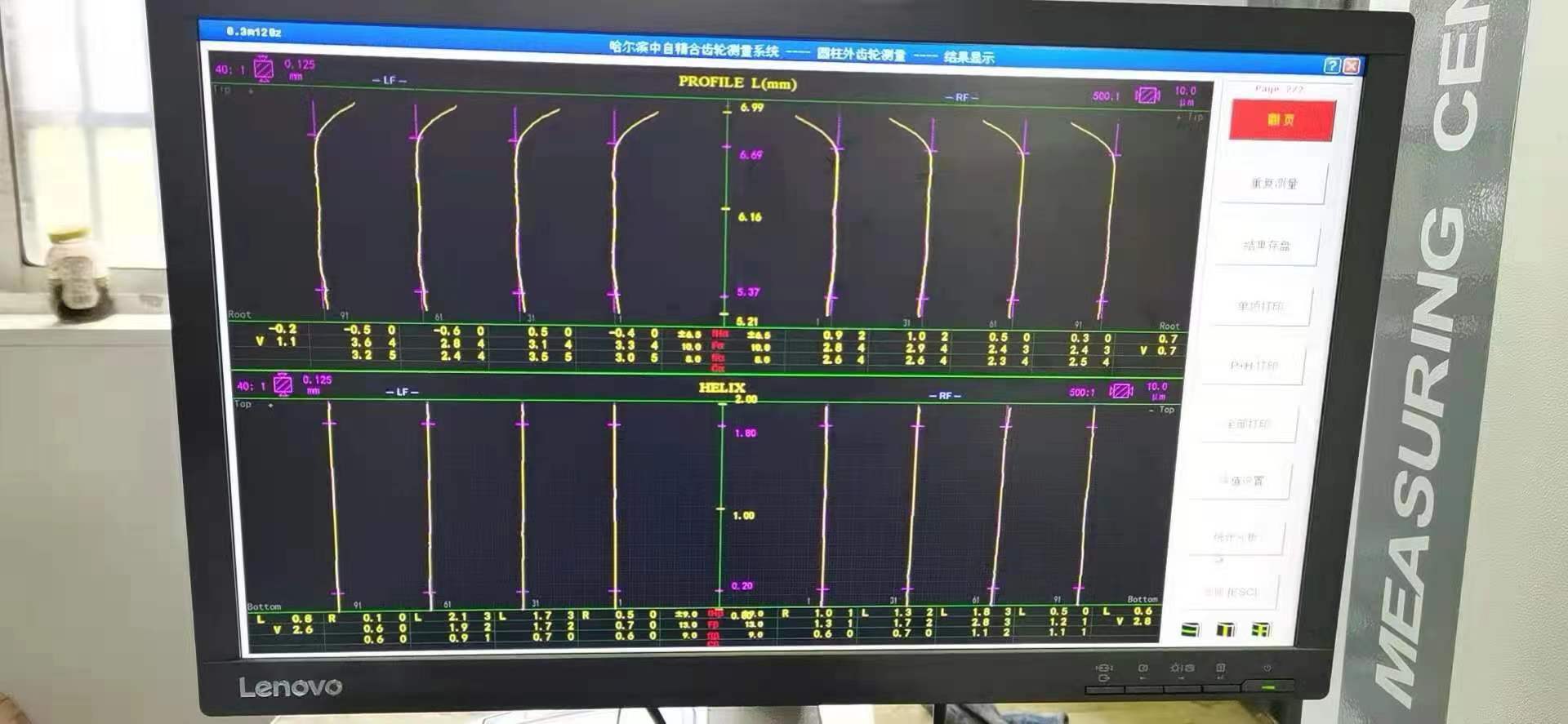

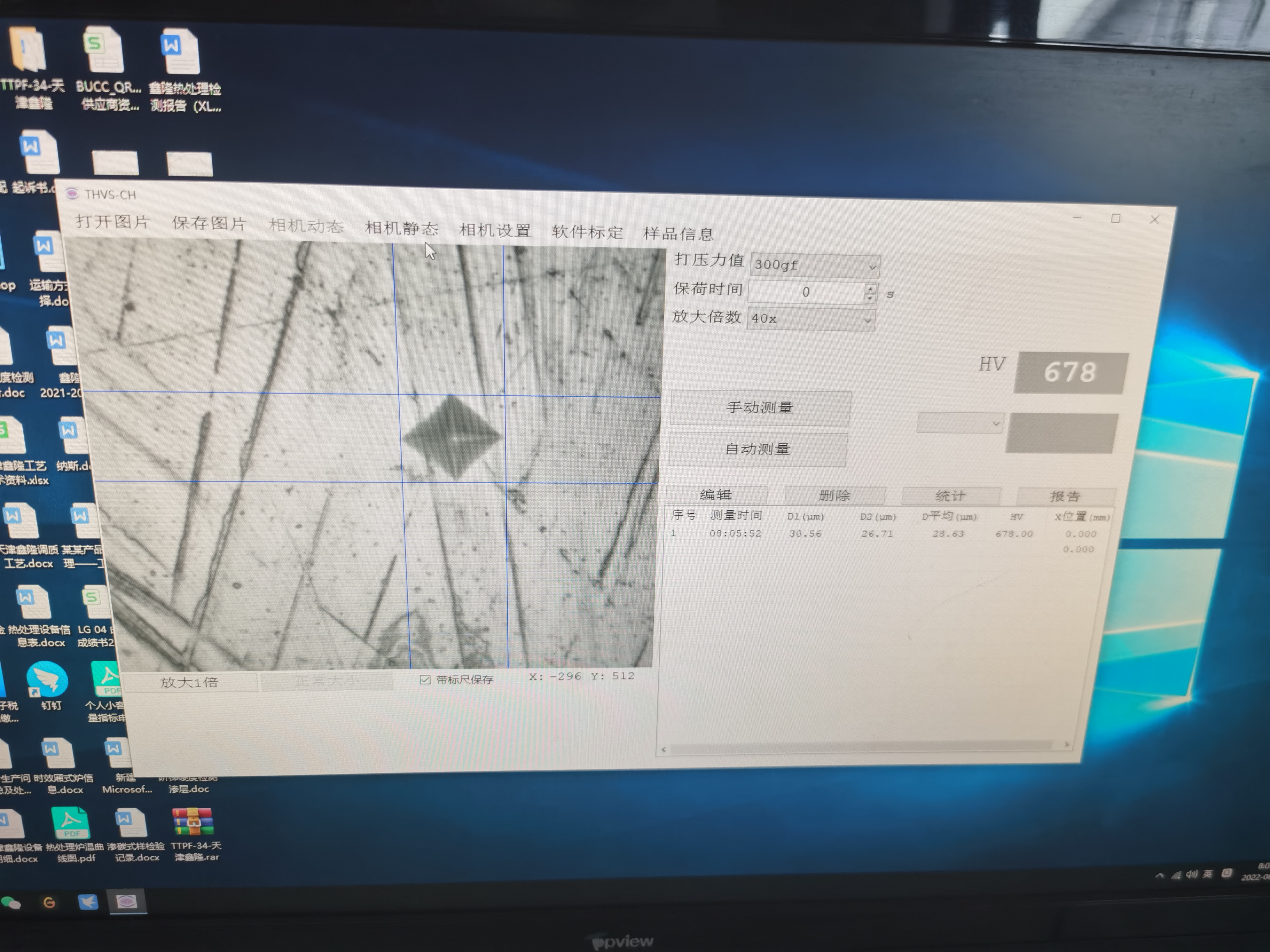

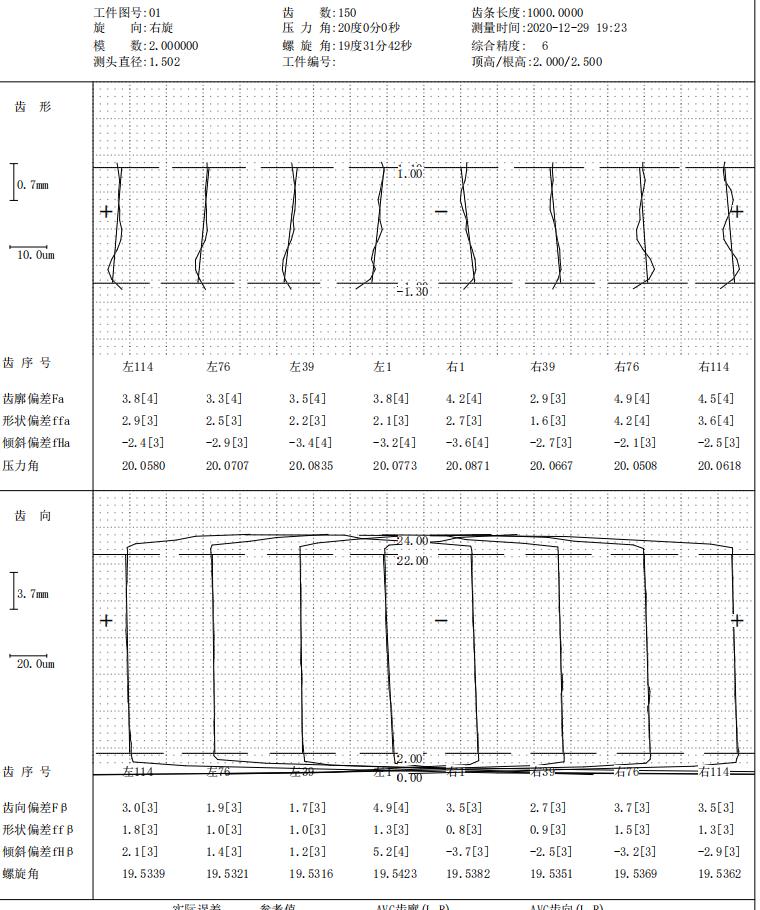

examine

Checking the accuracy and hardness of rack and pinion with three-coordinate measuring machine

VIEW MORE

You may like

-

0414.2023-1.75M-36Z Audis custom ground spur gear

-

Professional custom offset Frony sprocket pinion Primery transmission gear

-

European Standard M1 M2 M3 M4 M5 M6 Custom CNC Machining Steel Helical Gear Rack and Pinion M1.25

-

M4 tooth metal steel rack for automatic sliding door

-

Famous Taiwan YYC rack and pinion

-

Garage Door Opener Gear and Gear Shift Kit

-

Nylon Pinion CNC Rack and Pinion Plastic Circular Helical Gear Rack

-

Casement door rack and gear set

-

22mm thickness size sliding rack automatic door rack 22*22*1005m

-

High Quality Industrial Engraving Flexible Helical Rack Nylon Plastic Helical Rack for CNC Machines

Other Products

-

$1.00 / piece

$1.00 / piece -

$20.00 / set

$20.00 / set -

$10.00 / piece

$10.00 / piece -

$2.00 / piece

$2.00 / piece -

$0.60 / piece

$0.60 / piece -

$0.25 / piece

$0.25 / piece -

$0.50 / meter

$0.50 / meter -

$14.50 / piece

$14.50 / piece -

$1.00 / piece

$1.00 / piece -

$5.00 / piece

$5.00 / piece