WX-958 Manual 45L Volume Powder Coating Machinery

-

Supplier: Shanghai Peixu Machinery Equipment Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Helen Yin -

Price: $247.00 /set -

Min. Order: 1 set

Product details

| Condition: | New; | Marketing Type: | Ordinary Product; |

| Output Power Voltage: | 0-100kv; | Product name: | Powder coating machine; |

| Machinery Test Report: | Provided; | Machine Type: | powder coating machinery; |

| Output Powder Volume: | Max. 450g/Min; | Brand Name: | Vevor; |

| Type: | powder coating machinery; | After-sales Service Provided: | Video technical support,Online support; |

| Work temperature: | -10℃~45℃; | Gun Weight: | 480g; |

| Maximum Output Current: | 150Ua; | Selling Units: | Single item; |

| Warranty of core components: | 1 Year; | Place of Origin: | Jiangsu China; |

| Weight: | 28kg; | Dimension(L*W*H): | 520*520*660mm; |

| Frequency: | 50/60Hz; | Warranty: | 2 years; |

| Power Voltage: | AC110V; | Polarity: | Negative; |

| Packaging Detail: | Carton package WX-958 Manual 45L Volume Powder Coating Machinery; | Core Components: | other; |

| Single package size: | 60X49X48 cm; | Input Power: | 50W; |

| Single gross weight: | 23.0 KG; | After Warranty Service: | Online support; |

| Power: | 50W; | Video outgoing-inspection: | Provided; |

| Certification: | CE; | Local Service Location: | none; |

| Applicable Industries: | Building Material Shops,Machinery Repair Shops,Construction works ; | Key Selling Points: | Easy to Operate; |

| Showroom Location: | none; |

WX-958 Manual 45L Volume Powder Coating Machinery

Product Description

| Product name | Powder coating machine |

| Power Voltage | AC110V |

| Frequency | 50/60Hz |

| Input Power | 50W |

| Electromagnetic Valve Control Power Voltage | DC110V |

| Maximum Output Current | 150Ua |

| Output Power Voltage | 0-100kv |

| Work temperature | -10℃~45℃ |

| Output Powder Volume | Max. 450g/Min |

| Polarity | Negative |

| Gun Weight | 480g |

| Length Of Gun Cable | 4m |

| Powder Hopper Volume | 45L |

| Size | 520*520*660mm |

| V/N Weight | 35kg/28kg |

| Powder Coating Applicable | All Kinds Of Powder Without The Metals |

Electrostatic Powder Coating Machine is a dry finishing process, using finely ground particles of pigment and resin that are generally electrostatically charged and sprayed onto electrically grounded parts. The charged powder particles adhere to the parts and are held there until melted and fused into a smooth coating in a curing oven. Before coating, the parts to be coated are first pretreated similarly to conventional liquid coated parts. The pretreatment process is normally conducted in series with the coating and curing operatios.

Electrostatic spray machine works:

Electrostatic powder coating equipment (electrostatic spray machine) the powder coating to the surface of the work, under the action of electrostatic powder evenly adsorbed on the surface of the workpiece to form a powder coating, powder coating baked at high temperatures leveling solidified into varying results (the effect of different types of powder coatings) final coating.

This product is widely used in the home appliances, hardware, security door (window), fins, architectural, auto parts, sports equipment, medical equipment, aluminum and other industries.

Operating Instruction:

Attentions:

Check the following conditions if the air pressure is not enough:

Electrostatic spray machine works:

Electrostatic powder coating equipment (electrostatic spray machine) the powder coating to the surface of the work, under the action of electrostatic powder evenly adsorbed on the surface of the workpiece to form a powder coating, powder coating baked at high temperatures leveling solidified into varying results (the effect of different types of powder coatings) final coating.

This product is widely used in the home appliances, hardware, security door (window), fins, architectural, auto parts, sports equipment, medical equipment, aluminum and other industries.

Operating Instruction:

- Connect all the connecting lines and air tubes.

- Turn on switch of power supply (lighting indicator is on).

- Press the switch of spray gun to adjust voltage required (set by individual, voltage recommended is 60KV-80KV).

- Powder is placed into powder feeding barrel.

- Press the switch of spray gun and adjust to high-voltage. Start work if the powder is sprayed.

Attentions:

- Grounding line is attached with the equipment and must be connected with the spray booth, which is to be connected with special clean ground. Workpieces, hanging articles and support must be connected with grounding line to prevent grounding failure from making discharge sound.

- All compressed air must be kept tidy and dry, and has no oil or water. It is recommended that the customer use frozen and dried air sources. If the customer uses general oil-water separator, the oil and water must be regularly discharged in case that the coating ratio will be influenced by water accumulation in air box of powder barrel, solenoid valve and air tubes or too much humidity.

- If abnormal powder spray (i.e. bigger or smaller from time to time) happens to new equipment, generally that’s because powder feeding and lending air pressures are not properly adjusted. Powder spray increases as powder feeding air pressure increases. Adjust the powder blending air pressure to a higher level to ensure that powder spray is in uniform.

- Powder pump and spray gun should be blown and tidied up with compressed air after they are used for some time.

- Pressure regulating valves own locking device, in which “Push” means “off”, “Pull” means “on”. The buttons of various regulating valves should be adjusted to proper position (as is to be indicated by satisfactory powder spray).

Check the following conditions if the air pressure is not enough:

- Whether the air pressure in compressor is more than 6kg.

- Whether there is a leakage in the air tubes.

- Whether pressure regulating valves are in good condition. Generally the pressure regulating valves are easy to adjust, anticlockwise direction to the end (off) or clockwise direction to the end (maximum). Do not regulate them violently. If the pressure can’t be adjusted to a higher level, the equipment will not be used until relevant solutions are found and failures are repaired.

Product Images

Product features

- With flat and smooth appearance and workpiece with no deep corners.

- High sensitivity and durability.

- Thickening resistance to puncture the tip, the low maintenance rate.

- With circuit protection, voltage self-adjusting function, to ensure a perfect spraying effect.

- High voltage module near the nozzle, low voltage loss, replaceable high voltage components to bring convenience to the maintenance.

- Large flow of pneumatic components, in the smaller air pressure, can still achieve higher powder.

- All stainless steel for powder cartridge, can not use tools to easily remove all parts and clean.

- Two central gas design, so that the needle is no longer needle-guided fluid powder, to enhance the discharge effect, improve the rate of powder.

- Rotating atomized air flow is greatly improved coating quality.

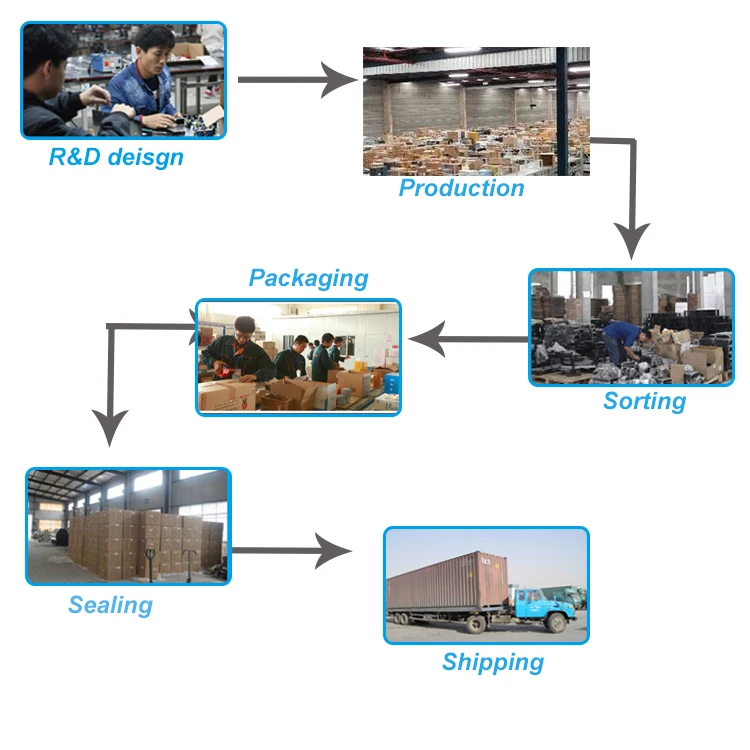

Packaging & Shipping

- 1 × Manual Powder Gun With Gun Cable

- 1 × Powder Gun Spare Parts

- 1 × Control Unit

- 1 × Powder Injector

- 1 × Fluidized Powder Hopper

- 1 × Trolley

- 1 × Oil-Water Separator

- 1 × Pressure Regulating Valve

- 1 × Powder Hose ,Air Tubes ,Grounding Line

Company Information

Vevor Machinery Equipment co., LTD. was founded in 2007, mainly engaged in cross-border business for 8 yeas. Our headquarters is in America, and controlled office is in Hong Kong, Los Angeles, Portsmouth, and Sydney. There are logistics warehouses in Los Angeles, Portsmouth, Sydney. Logistics warehouse distribution in Los Angeles can cover customers throughout North America, logistics warehouse distribution in Portsmouth can cover the whole European customers, and logistics warehouse distribution in Sydney can cover the whole Oceania Australia customers.

Certifications

VIEW MORE

You may like

-

Powder Coating Industrial Oven Powder Coating Oven

-

Vacuum coating machine

-

Industrial grade chrome plating machine booth spray paint chrome plating machine

-

Gema Optiflex 2 Vibrating Box Feed Metal Electrostatic Powder Coating Machine Vibrating Powder Coating Machine

-

Stainless steel 10L spray chrome coating machine paint coating nano chrome plating machine

-

Hot Sale Classic Portable Manual Electrostatic Powder Coating Machine (WX-101)

-

High quality automotive hub sputtering vacuum coating machine

-

CE approved industrial powder coating curing oven gas electric stand for sale in China

-

Secondary Vacuum Coating Machine/Vacuum Coating Machine

-

Promote products Mirror spray chrome plating Fine surface spray chrome plating equipment

Other Products

-

$50.00 / set

$50.00 / set -

$50.00 / set

$50.00 / set -

$180.00 / set

$180.00 / set -

$158.00 / set

$158.00 / set -

$160.00 / piece

$160.00 / piece -

$538.00 / set

$538.00 / set -

$54.00 / set

$54.00 / set -

$223.00 / set

$223.00 / set -

$95.00 / piece

$95.00 / piece -

$100.00 / set

$100.00 / set

Related Search

manual powder coating machin suppliers

powder coating machine

powder coating line

powder coating

powder coating paint uv

metal coating machinery importers suppliers

automationed vacuum coating machinery

wagner powder coating equipment

powder coating pcb

white color polyester electrostatic powder coating