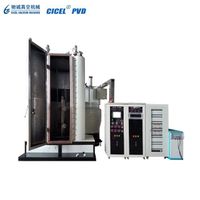

Secondary Vacuum Coating Machine/Vacuum Coating Machine

-

Supplier: Yiwu Mingfeng Vacuum Coating Material Co., Ltd. -

Region: Zhejiang, China -

Price: $10000.00 / 1 - 1 sets

$9900.00 / 2 - 4 sets

$9800.00 / >=5 sets -

Min. Order: 1 set

Product details

| Type of machine: | 1.8m x 2m | Coating Color 1: | the gold |

| weight: | 6 tons | Local service location: | Pakistan |

| use: | Evaporation decoration | Dimensions (L*W*H): | 1mx1mx2m |

| Warranty: | unavailable | Video shipment inspection: | if |

| Coating Color 4: | Red | Matrix: | aluminum |

| Main selling points: | easy to operate | Applicable industries: | Vacuum coating machine |

| year: | 2016 | Types of: | Coating production line |

| Name: | Vacuum coating machine | Coating Color 2: | silver |

| place of origin; place of origin: | Zhejiang, China | Voltage: | 220v/380v/50hz |

| Supply capacity: | 10 pieces per month | Package preview: | |

| Packaging Details: | container | After warranty service: | online support |

| Certification: | ISO9001 | Coating Color 5: | blue |

| Showroom location: | Pakistan | State of health: | used |

| Coating Color 3: | 7 Chinese cabbage | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Core component warranty: | 1 year | port: | Haining, Guangdong, Shenzhen |

| Core components: | engine, pump | Marketing Type: | normal product |

| coating: | Vacuum coating | strength: | 50 Hz |

| Mechanical test report: | if |

Product Description

The vacuum coating machine is suitable for vacuum coating of any background color such as plastics, ceramics, resin crafts, glass, etc.

Plated into gold, silver, colorful, red, purple, blue, gray, black and other bright colors, mainly used for scientific research

And surface coating in industries such as teaching, electronic components and coating production

Plated into gold, silver, colorful, red, purple, blue, gray, black and other bright colors, mainly used for scientific research

And surface coating in industries such as teaching, electronic components and coating production

Name | Vacuum coating machine |

use | Suitable for all kinds of jewelry coating |

user's guidance

Instructions for use

Vacuum evaporation coating equipment uses resistance heating in a vacuum chamber to melt metal coating materials

Gasification, so that metal molecules are deposited on the substrate, so that the metal film is smooth and high reflectivity, to achieve

The purpose of surface decoration and beautification

Gasification, so that metal molecules are deposited on the substrate, so that the metal film is smooth and high reflectivity, to achieve

The purpose of surface decoration and beautification

Description of application effect

Use effect description

Vacuum evaporation coating machine is to use the resistance heating in the vacuum chamber to melt and vaporize the metal coating material, so that the metal molecules are deposited on the substrate to obtain a smooth high-reflectivity metal film layer to achieve the purpose of coating surface decoration and beautification

VIEW MORE

You may like

-

Powder Coating Industrial Oven Powder Coating Oven

-

Vacuum coating machine

-

Industrial grade chrome plating machine booth spray paint chrome plating machine

-

Gema Optiflex 2 Vibrating Box Feed Metal Electrostatic Powder Coating Machine Vibrating Powder Coating Machine

-

Stainless steel 10L spray chrome coating machine paint coating nano chrome plating machine

-

Hot Sale Classic Portable Manual Electrostatic Powder Coating Machine (WX-101)

-

High quality automotive hub sputtering vacuum coating machine

-

CE approved industrial powder coating curing oven gas electric stand for sale in China

-

Promote products Mirror spray chrome plating Fine surface spray chrome plating equipment

-

Best selling spray paint chrome plating machine system 10L silver chrome plating machine for silver gold

Other Products

-

$15000.00 / set

$15000.00 / set

Related Search

secondary transformer winding machine

pvd vacuum coating machine

high quality vacuum aluminium coating machine

manufacturers vacuum coating machine suppliers

glass vacuum coating machine

offer vacuum coating machin suppliers

used vacuum coating machine

metal tools pvd vacuum coating machine

double vacuum machine

metal coating machine