Mini Simple Dry Cement Mortar Plaster Production Line Mixer Machine Premix Plant Mixing Equipment Manufacturer For Sale In India

-

Supplier: Henan Landao Machinery And Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Debbie Zou -

Price: $7000.00 /set -

Min. Order: 1 set

| Warranty of core components: | 1 Year; | Supply Ability: | 60 Set/Sets per Month Sand Cement Dry Powder Mix Mortar Production Line Plant; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Applicable Industries: | Building Material Shops,Manufacturing Plant,Home Use,Construction works ; |

| Operation workers: | 1--2 persons; | Warranty: | 1 Year; |

| Mixing time: | 5-8 mintues; | Local Service Location: | Indonesia; |

| Showroom Location: | Indonesia; | Marketing Type: | New Product 2019; |

| Packing capacity: | 10kg-50kg bag; | Dimension(L*W*H): | 3000mm*1300mm*2700mm; |

| Control System: | Electric control box; | Video outgoing-inspection: | Provided; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Credit; | Condition: | New; |

| Core Components: | PLC,Engine,Motor; | Weight: | 2500kg; |

| Port: | Shanghai, Qingdao, Tianjin, Ningbo Port China For Dry Mortar Machine Premix Plant Mixing Equipment Manufacturer For Sale; | Packaging Detail: | 1.FCL: iron wire fixed packed in Container 2.LCL:Plywood Case 3.Wire cables are used for fastening machine 4.All surface will be covered by plastic film 5.As your requirement Mini Simple Dry Cement Mortar Plaster Production Line Mixer Machine Premix Plant Mixing Equipment Manufacturer For Sale In India; |

| Brand Name: | LANDAO; | Place of Origin: | Henan China; |

| Machinery Test Report: | Not Available; | Mixing system: | horizontal spiral ribbon mixer; |

| Features: | Low Investment Small Start Business; | Power: | 7.5KW; |

| Name: | Dry Cement Mortar Plaster Production Line Mixer Machine Premix Plant; | Key Selling Points: | Easy to Operate; |

| Mixer type: | ribbon mixer; | Application: | Tile adhesive of dry mortar,gypsum powder,plaster,; |

| Certification: | CE ISO; | Packing machine: | Automatic weighing and packing machine; |

| CV: | <5%; | Voltage: | 220V-440V; |

| Raw material: | Cement, Sand, Flyash, Additives etc; | After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

Mini Simple Dry Cement Mortar Plaster Production Line Mixer Machine Premix Plant Mixing Equipment Manufacturer For Sale In India

What is Dry Mortar Used For

In the construction industry, mortar is a general term related to mixture of cement and sand in different proportions along with water. Mortar is used for masonry construction, flooring, plastering, and finishing, which will be in a wet state for application. In contrast to site mixed mortar, dry mix mortar is a term for readily mixed raw materials in dry form which may also have additives and polymers added for specific usage in construction.

Mini Simple Dry Cement Mortar Plaster Production Line Mixer Machine Premix Plant Mixing Equipment Manufacturer For Sale In India

| Item | 1-2ton/ h | 2-3ton/ h | 3-4ton/ h | 4-5ton/ h | 8-10ton/ h |

| Mixing power | 5.5KW | 7.5KW | 15KW | 11KW | 22KW |

| Feeding conveyor power | 3KW | 3KW | 4KW | 4KW | 4KW |

| Second conveyor power | 4KW | 4KW | 4KW | 5.5KW | |

| Mixing time | 5-8minutes | 5-8minutes | 5-8minutes | 5-8minutes | 5-8minutes |

- Simple Dry Cement Mortar Plaster Production Line is horizontal spiral ribbon mixer, has three layer inside and outside dry mortar plant

- Horizontal dry mortar mixer tank is equipped with a moving door to easy to clear up, Can be made of carbon steel, stainless steel, stainless steel mixer according to customer required.dry mortar machines

- Conveyor can fast moving material,save mixing time:6-8minutes per batch.

- Automatic weighing and packing machine:5-8seconds/bag.dry mortar machines

- Weight of bag:10kg-50kg,open mouth or valve port can do.dry mortar plant

Some of the Dry Mortar Mixer Machine Premix Plant Mixing Equipment Include

1.Plastering-Internal /External dry mortar machines dry mortar machines

2.Thin Joint Mortars dry mortar mixer dry mortar mixer

3.Floor Screeds dry mortar production mixer

4.Stuccos dry mortar mixer

5.Cement Grouts premixed dry mix mortar plant

6.Tile Adhesive dry mortar mixing equipment

7.Tile Joint Fillers dry mortar plant

8.Waterproofing Products dry mortar mixing equipment

9.Crack Fillers and Repair Materials dry mortar machines

dry mortar mixer dry mix mortar plant small dry mortar mixer dry mortar mixing machine

The advantages for Mini Simple Dry Cement Mortar Plaster Production Line include: dry mortar plant

1. Factory made dry mortar with quality certification as per standards

2. Usage of quality raw materials as per the applicable standards

3. Green products for environment sustainability dry mortar machines

4. Educating the users on good construction practices and quality of the contents

5. Pursuing the industry to deliver structures with good standards

6. Testing of products for all technical parameters and creating awareness about the technical attributes to users for choosing the right product

7. Proper quantification of materials and reduction in wastage

8. Speed premixed dry mix mortar plant

9. Hassle free and ease of application and usages dry mortar mixing equipment

| What are our advantage of our team and factory? |

| 1.We have more than 60 machines and will guarantee the short production time and good quality.dry mortar plant |

| 2.We are located in Henan Province China,the largest construction town,there is a large advantage on experience and cost.it is easy for you to visit our company and the factory.we will also provide you 24h online chat service.dry mortar machine |

| 3.Online chat,quick reply,good quality.dry mortar mixer |

|

4.Henan Landao Machinery and Equipment Co.,Ltd. is mainly engaged in Building Machinery(concrete mixer,concrete batching plant,concrete pump,concrete truck,ect),Construction Equipment(dry mortar processing machine,asphalt plant,brick block making machine,ect.),Road Maintenance Machine(road roller,concrete trowel,concrete screed,road cutting machine,plate compactor,ect),Steel Bar Processing Machine(steel bending machine,steel cutting machine,thread rolling machine,Straightening machine,ect),Agriculture Machinery(auger drill,gass chaff cutter,ect).we have head manufacture factory of our own since 1982. |

- This system has improved as an effective dry cement mortar plaster production line on the basis of multi spiral ribbon dry mixer.

- The finish product feed into storage silo through twice elevator can complete filling without interfering next materials to produce.dry mortar mixing equipment

- Dry mortar mixer machine premix plant mixing equipment can multiply productivity with accurate quantative packaging machine dry mortar mixer

Europe: Portugal, Kosovo, Lithuania, Russia, Macedonia,Spain etc

North America: the United States, Guatemala, Trinidad and Tobago,Canda,etc

South America: Chile, Guyana,Peru,etc dry mortar production mixer

Oceania: Australia,Papua New Guinea,etc premixed dry mix mortar plant

Africa :Algeria, Nigeria, Cameroon, Zimbabwe, Malawi, Zambia, Cameroon,etc

Asia: India,Indonesia, Singapore, Saudi Arabia, Yemen, Oman, Uzbekistan, Vietnam, Malaysia, Thailand, Philippines,Kyrgyzstan,South Korea, Bangladesh,etc.

1.Provide Research & Development Service,For Customer Exclusive Model.

2.Provide OEM and ODM Service.dry mortar plant

3.More than 4 Years Export Experience,Proseffional Mature Skill

4.Welcome Small and Big Size Customer Orders.dry mortar machines

5.After Sales Service with 12 Month Warranty dry mortar production mixer

6.With Great Garden You Are Not Alone After Your Purchase.Full AfterSales Phone and Email Support dry mortar mixing equipment

| Delivery time: 20 days after receipt payment |

| Payment terms: 30% T/T in advance, the balance is paid (by T/T) before shipping from factory |

| Package dry mortar machines |

|

1.Wire cables are used for fastening simple dry cement mortar plaster mixer machine on the trailer or inside the container |

| 2.Cork wood are placed in front or behind dry mortar production line mixer machine to protect it |

| 3.Plastic film is covered on dry mortar premix plant mixing equipment as a rain-roof |

What kind of product do you produce?

How many the capacity per hour do you want?

| Q1:What is the area occupied? |

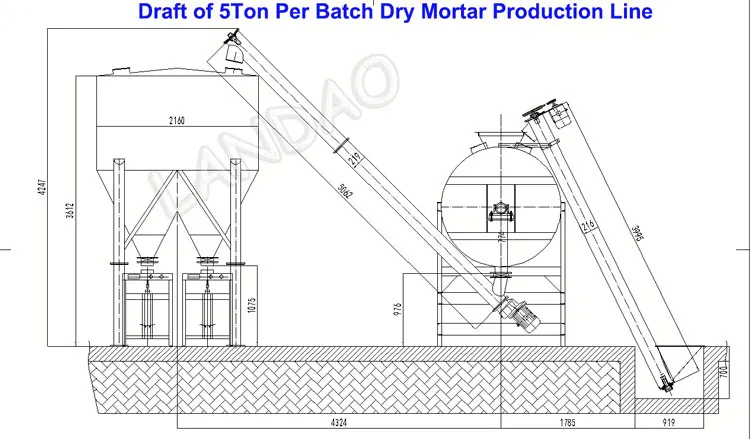

| A1:A complete simple 5 ton per hour Simple Dry Cement Mortar Plaster Production Line is about 20 m2 and height is less than 1 meters |

| Q2:How about the power consumption? |

| A2:For 2ton/h complete dry mortar production line,that need 80-100Kwh for 8 hours,for 4ton/h line,it need 120-140Kwh for 8 hours.for 5ton/h line,it need about 220-240Kwh for 8 hours |

| Q3:Weather can choose the packaging machine? |

|

A3:Of course,we have simple packing machine and automatic packing machine(automatic weighing and automatic packing).we can do valve port and open port packaging machine according to your bag |

GET HOME>>>>>>>>>>>>>

GET HOME>>>>>>>>>>>>>

-

Cheap dry mortar mixer from China with high productivity

-

hot sale dry cement mixer for mixing sand and cement / automatic dry mortar production line equipment

-

Sincola Ready Mixed Gypsum Cement Tile Adhesive Mixer Glue Production Line

-

Toolmore 100 Liter Portable Concrete Mortar Mixer

-

cement sand mixing bagging machine cement mortar mixer

-

Simple caulk mixer production line

-

Low investment and high efficiency simple dry powder mortar production line

-

Small business tile adhesive machine price

-

Simple dry powder mortar production line cement mortar mixer wall putty mixing equipment tile glue making machine

-

Energy-saving equipment cement mortar mixing line mixer price

Other Products

-

$15500.00 / set

$15500.00 / set -

$999.00 / set

$999.00 / set -

$5600.00 / set

$5600.00 / set -

$950.00 / set

$950.00 / set -

$500.00 / set

$500.00 / set -

$800.00 / set

$800.00 / set -

$3000.00 / set

$3000.00 / set -

$8500.00 / set

$8500.00 / set