Waste PP PE HDPE Recycling Plastic Film Pelletizing Machine

-

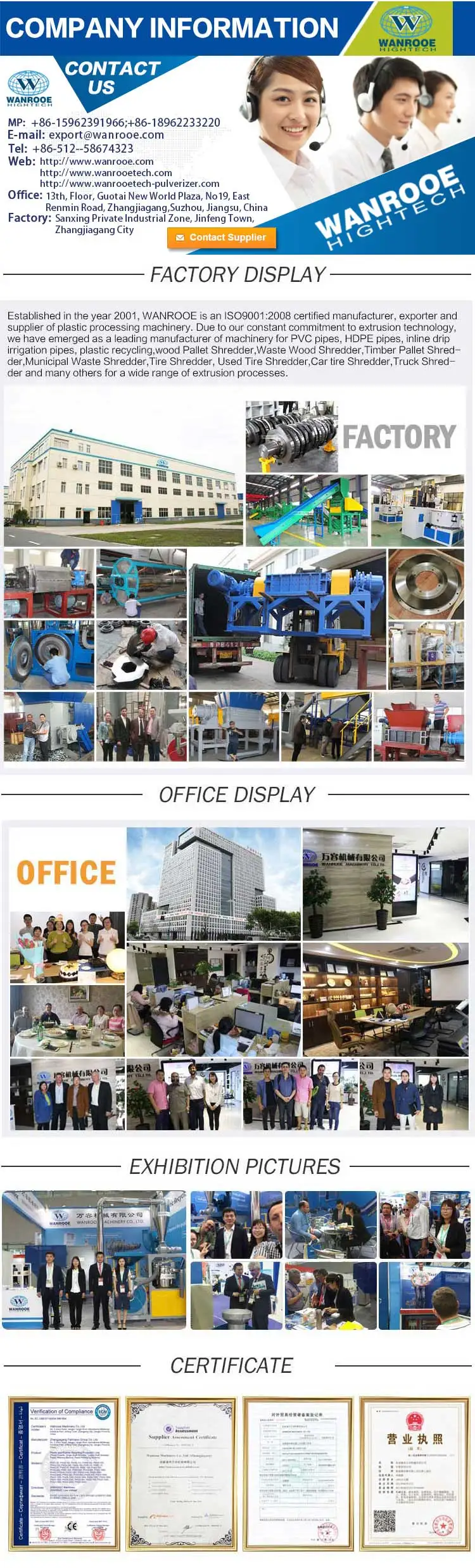

Supplier: Wanrooe Machinery Co., Ltd. (Zhangjiagang) -

Region: Jiangsu, China -

Contact: Mr Anthony Xia -

Price: $3000.00 /set -

Min. Order: 1 set

| temperature controller: | Japan RKC; | Payment Terms: | L/C,T/T,Western Union; |

| Product name: | Waste PP PE HDPE Recycling Plastic Film Pelletizing Machine; | Supply Ability: | 500 Set/Sets per Year Waste PP PE HDPE Recycling Plastic Film Pelletizing Machine; |

| After Warranty Service: | Video technical support,Online support; | Dimension(L*W*H): | Depending on the model; |

| Machinery Test Report: | Provided; | Condition: | New; |

| screw diameter: | 100mm; | Warranty: | 1 YEAR; |

| Key Selling Points: | Automatic; | extruder type: | single screw; |

| company brand: | wanrooetech; | Certification: | CE; |

| vacuum pump power: | 3kw; | certification: | CE; |

| Packaging Detail: | Waste PP PE HDPE Recycling Plastic Film Pelletizing Machine wrapped with film then come into wooden case for container shipping; | Warranty of core components: | 1 YEAR; |

| Applicable Industries: | Manufacturing Plant; | After-sales Service Provided: | Video technical support,Online support; |

| Marketing Type: | New Product 2020; | Video outgoing-inspection: | Provided; |

| Showroom Location: | indonesia,pakistan; | Place of Origin: | Jiangsu China; |

| Brand Name: | Wanrooe; | desgassing method: | two vacuum desgassing port; |

| Port: | Shanghai; | Core Components: | PLC,engine,MOTOR; |

| L/D ratio: | 33:1; | Plastic Type: | PE,PP/PE,PP; |

| Local Service Location: | indonesia,pakistan; | power source: | 380v 50hz; |

Waste PP PE HDPE Recycling Plastic Film Pelletizing Machine

In order to better give you professional answers, when sending the inquiry, please describe your parameters or technical requirements (such as: processing materials, output size, capacity, etc.) and attach your contact information (such as phone number, e-mail, facebook, whatsapp, wechat, etc.)

Applications:

This water-cooling single screw plastic pellet making machine is single stage plastic regenerative pelletizer, which is suitable for many kinds of plastic waste materials recycling and making pellets, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc. The film can be pressed in the compressor and then be pelletized.

Description:

This water-cooling single screw plastic pellet making machine is one stage plastic regenerative pelletizer, which is suitable for many kinds plastic waste materials recycling and making pellet, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc. The film can be pressed in compressor and then be pelletized.

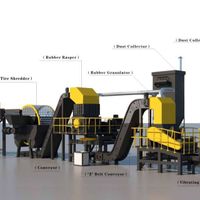

Process flow:

Conveying feeding→ Metal detector →Film Agglomerator /Compactor →Degassing single screw extruder →Hydraulic filer exchanger→ Mould head →water ring cutting →Dewatering machine→ Air dryer Blowing system→ Storage hoper→ Finished product packing.

Components:

Detailed description of each items:

1. Conveyor: convey PP PE film or flakes into compactor.

2. PE film Agglomerator /Compactor: crushing and compress film, and feed compressed film into extruder forced, to make the production capacity high and stable.

3. Extruding system: plasticizing material and exhausting gas.

4. High speed Net exchanging system and Die-head: filter material impurity, to make production more stable.

5. water ring pelletizing machine: cutting pellets in water.

6. Water tank: cooling pellets.

7. Dewater machine: make pellets dry.

8. Vibration sieve: remove bad pellet and keep good pellet.

9. Air Blower: convey good pellets into silo.

10: Storage silo: keep pellet.

Equipment List:

| 1 | Belt conveyer (can equip the metal detector ) |

| 2 | Agglomerator /Compactor machine |

| 3 | Extruder |

| 4 | Die head and screen changing device |

| 5 | Water ring cutter |

| 6 | Vibrating screen |

| 7 | Vertical dewatering machine |

| 8 | Air drying system |

| 9 | Cyclone hopper |

Features:

1. Allow free assembling of the screw component, based on raw material type.

2. Using the suitable die head for palletizing, such as water ring cutting, under-water cutting and hot face cutting.

3. High efficient force feeder ensures stable high capacity material feeding, low power consumption.

4. Main screw has vacuum exhaustion.

5. Water ring granulator machine, attached with dryer. 6. Single screw extruder, with specially designed screw, barrel, venting system, ensure the good quality of the final products.

7. Pelletizing style: standard cutting with extrusion mould. Even cutting ensures with good shape.

Application:

| Model | PNHS-85 | PNHS-100 | PNHS-130 | PNHS-160 | PNHS-180 |

| Screw Dia. (mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-36 | 25-36 | 25-33 | 25-33 | 25-33 |

| Capacity (kg | 120-180 | 200-250 | 400-500 | 450-700 | 500-1000 |

-

Unvulcanized Steel Cord Scrap Rubber Steel Wire Separator

-

Tire recycling plant for waste recycling equipment

-

Semi-automatic waste tire recycling into rubber powder machine tire cutting machine

-

High-performance used tire recycled rubber production line rubber powder making machine tire recycling production line

-

Reclaimed rubber production equipment

-

Used tire cutting machinery, tire recycling machinery for sale

-

Factory sale 1-2 tons waste tire rubber shredder recycling plant

-

Waste tire wire separator/tire wire remover/tire wire remover

-

Zero consumption tire doubling machine used tire doubling machine for sale

-

waste tire recycling machine used tire recycling shredder factory in pakistan

Other Products

-

$1000.00 - $10000.00 / set

$1000.00 - $10000.00 / set -

$5000.00 - $25000.00 / set

$5000.00 - $25000.00 / set -

$3000.00 / set

$3000.00 / set -

$5000.00 / set

$5000.00 / set -

$12000.00 / set

$12000.00 / set -

$5000.00 / set

$5000.00 / set -

$4000.00 / set

$4000.00 / set -

$3000.00 / set

$3000.00 / set -

$40000.00 / set

$40000.00 / set -

$20.00 / piece

$20.00 / piece