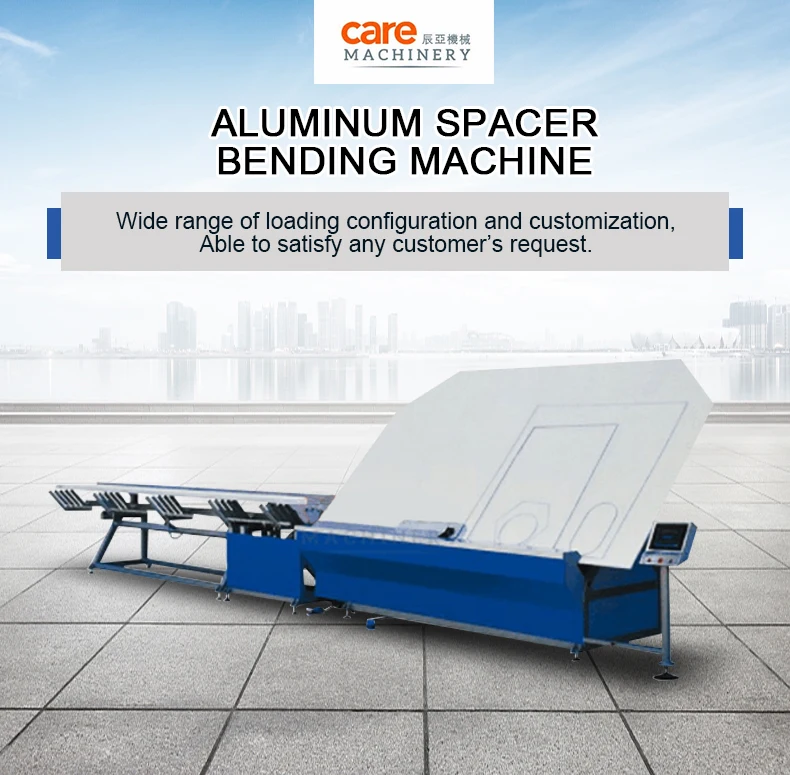

Aluminum Spacer Semi Automatic Bending Machine

-

Supplier: Shandong Care Machinery Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Care Machine -

Price: $8500.00 /set -

Min. Order: 1 set

| Function: | Spacer bending; | Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Construction works ; |

| Max bending size: | 2000x2000mm; | Warranty: | 12 Months; |

| Key Selling Points: | High-accuracy; | Certification: | CE ISO; |

| Product Name: | Insulating Glass Machine Aluminum Spacer Bending Machine; | Brand Name: | Care; |

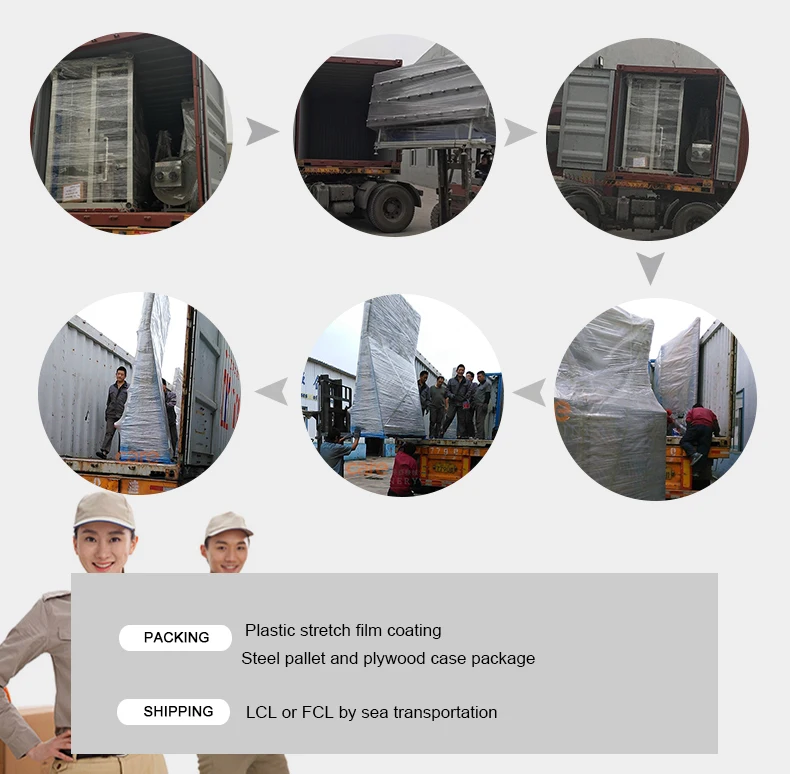

| Packaging Detail: | 1, plastic stretch film coating; 2, steel pallet and plywood case package; 3, LCL or FCL by sea transportation;; | Weight: | 400kg; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Condition: | New; |

| Model Number: | CALWJ-02; | After-sales Service Provided: | Online support,Engineers available to service machinery overseas; |

| Voltage: | 380V 50HZ; | Production Capacity: | 120m/min; |

| Power: | 3.5kw; | Place of Origin: | Shandong China; |

| Dimension(L*W*H): | 9800x2100x2200mm; | Spacer width: | 5.5-26.5mm; |

Aluminum Spacer Semi Automatic Bending Machine

The machine is used for aluminum bar bending, which used as spacer in insulating glass sheet.

Parameters of Care Aluminum spacer bending machine | ||

Power supply | 380V 50Hz 3P (or customized) | |

Total power |

| 3.5KW |

Working parameters | Aluminum spacer width | 5.5-26.5mm |

Feeding speed | 120m/min | |

Air pressure | 0.4-0.6MPa | |

Max processing size | 2000x2000mm | |

Dimension | L×W×H (mm) | 9800x2100x2200 |

1. PLC controlling system, touching screen operation;

2.CNC servo motor feeding and bending;

3. World famous brands of key components, ensure stable operation and long service life;

4. Automatic adjustment of processing speed according to aluminum spacer size;

5. Workable for square, retangle and avrious abnormal shaped;

We are quality conscious company, and it’s just our origin to supply customers qualified machines. We are always trying to be the “Solution Expert of Glass Processing Facilities”. We not only supply complete glass processing facilities, but our professional engineer team also provide right facility configuration, accordingly customers’ various production requirements and estimated investment. And we’ll provide essential industrial design and technical guidance as well.

We “Care What You Care”, and supply products and service beyond expectation.

-

Insulated double glass spacer profiler for manufacturing and production of aluminum gasket profiler

-

CE/UL insulating glass making machine double-layer glass machine insulating glass production line

-

Production line of glass insulators

-

CE certification and new status insulating glass machine/double glazing machine/insulating glass production line

-

CNC Glass Cutting Machine Float Glass Cutting Machine Multifunctional Glass Cutting Machine

-

Sealant Sealer / Sealant Extruder

-

Glass Bottle Making Machine Production Line 2020 China Glass Bottle Furnace / Glass Bottle Furnace Production Line Project "This in Hand"

-

Glass Grinding Machine Glass Grinding Polishing Machine Portable Glass Edge Grinding Polishing Machine

-

SY-1000 single side horizontal glass edging machine

-

glass production line

Other Products

-

$8500.00 / set

$8500.00 / set -

$5200.00 / set

$5200.00 / set -

$1450.00 / set

$1450.00 / set -

$2560.00 / set

$2560.00 / set -

$1200.00 / set

$1200.00 / set -

$900.00 / set

$900.00 / set -

$2700.00 / set

$2700.00 / set -

$1200.00 / set

$1200.00 / set -

$4800.00 / set

$4800.00 / set -

$1200.00 / set

$1200.00 / set