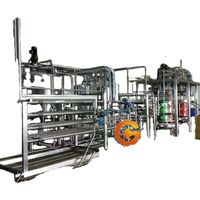

counter pressure retort autoclave for food with vacuum packaging film anti inflation bag

-

Supplier: Guangzhou Jiangbin Trade Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Sophia Chen -

Price: $1000.00 /set -

Min. Order: 1 set

| Place of Origin: | Jiangsu China; | Weight: | 105kg; |

| Certification: | ISO; | Dimension(L*W*H): | 700*680*1300; |

| Applicable Industries: | Food & Beverage Factory,Restaurant,Food Shop,Food & Beverage Shops; | Power(W): | 4.5kw; |

| Brand Name: | JIBIMED; | Product name: | counter pressure retort autoclave; |

| Condition: | New; | Port: | Guangzhou,Shenzhen,Shanghai; |

| After-sales Service Provided: | Free spare parts,No overseas service provided; | Voltage: | 220v/110v; |

| Warranty: | 1 YEAR; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union; |

| Supply Ability: | 1000 Set/Sets per Month; | Packaging Detail: | in wooden case; |

LS-35LD, LS-50LD, LS-75LD, LS-100LD, LS-120LD, LS-150LD counter pressure sterilizer is microcomputer-program -controlled,which is adopts electric heating method. The water is directly injected into the sterilization chamber to heat, and generates the high-pressure steam required for sterilization purpose. After the sterilization is finished, the compressed air is externally supplied for proceed the cooling for 3 minutes, the temperature inside would lower 30~40℃. The sterilizer is designed to perform both boiling sterilization and rapid cooling pressure sterilization. The boiling range is set at ≤100 °C. The rapid cooling pressure sterilization range temperature is pre-selected from 105 ° C to 134 ° C. The heating tubes are provided with overload protection ,and the buzzer would alarm to indicate the sterilizing end. It is easy to operate, safe and reliable, which is suitable for disinfection and sterilization of food packaging and utensils, equipment and other items and especially suitable applying in food research institutes for sterility testing.

Normal working conditions

1)Ambient temperature +5℃~+40℃

2)Relative humidity ≤85%RH

3)Atmospheric pressure 70kPa~106 kPa

4)power supply: AC220V±22V,50Hz±1Hz(all the grounding wires should

meet the requirement.

5)water resource pressure: 0.15 ~0. 2 5MPa

6)aire resure pressure: 0.24 MPa

Shipment and storage conditions:

1)Ambient temperature: -10~50℃

2)Relative humidity: 10%~90%

3)Atmospheric pressure range: 50~106kpa

The sterilizer is equipped with safety valve, which would automatically release while the pressure exceed 0.25mpa, and the power supply would directly be cut off while the temperature exceed 140 ℃. And also with over-current loading protection, safe and reliable.

2 BASIC PARAMETER

Table 1 basic parameter

MODEL

| Chamber size(L)

| Rating working pressure (MPa)

| Rating working temperature (℃) | Rating input consumption (kW) | timer(min) | Pressure(mpa)/ Temperature(℃) range (MPa/℃)

| DIMENSION (CM) | G.W/N.W(kg) |

LS-35LD | 35 | 0.22 | 134 | 1×2.5 | 0~99 | 0.07~0.22/ 105~134 | 48×46×85 | 56/42 |

LS-50LD | 50 | 2×1.5 | 52×52×98 | 65/55 | ||||

LS-75LD | 75 | 3×1.5 | 56×56×98 | 90/70 | ||||

LS-100LD | 100 | 59×59×108 | 105/85 | |||||

LS-120LD | 120 | 3×2 | 60×64×114 | 125/100 | ||||

LS-150LD | 150 | 67×69×114 | 135/110 |

3 CHARACTERISTICS

a) Equipped with a pressure/temperature controller, the pressure setting range is 0.07 to 0.22MPa (corresponding to a saturated steam temperature of 115 to 134°C).

b) Equipped with safety valve, by the sterilizing pressure exceed the allowable figure, which would release the pressure automatically.

c) Equipped with immersed heating tube, with anti-dry function, while the water is in low level, the unit would cut off the power to stop the heating and alarm.

4 CONSTRUCTION

1. Inlet faucet 2. Tighten bolts 3. Handle 4. Control panel 5. breaker switch 6. Air inlet 7. Power cord

8. exhaust port 9. water outlet 10. safety valve 11. nameplate

(Pic 1 CONSTRUCTION)

5 WORKING PRINCIPLE

This product is designed for two kinds of disinfection and sterilization:. Direct heating to produces pressured steam. Then the pressure steam acts on the microorganisms to destroy its structure then achieve sterilization purposes. For the rapid cooling and sterilization procedure, firstly injected 6 liters tap water into the chamber, and then heat for about 25 minutes to proceed the sterilization and at the meanwhile the temperature inside in maintained. The sterilization time is 35-40 minutes. After the completion, 0.24MPa-compressed air is manually injected into the chamber, and then the drain valve is 1/2 opened for drainage, for those soft packages are counter pressured cooled. Quickly cooling for 3 minutes, manually turn off the entering of the compressed air and tap water, the temperature of the objects in the chamber can be lowered to 30 ~ 40 °C.

Packing detail:

Delivery detail:

1.We ship autoclave by UPS/DHL/FEDEX/TNT express which is door to door ,you no need go out can get the autoclave,takes 3~ 5 days to arrive.

2.We can also help you ship the autoclave by air cargo which you need to go to Air port to take autoclave home,it takes about 2-7 days to arrive.

3.If autoclave are large quantity and you not need the autoclave so urgently ,you can choose by sea to save some freight cost which takes about one month to arrive .

No matter what delivery way ,depending on your actual requirements.

-

Small ultra-high temperature sterilized milk processing plant milk tray type ultra-high temperature sterilizer

-

Food processing water spray sterilizer pot sterilizer machine made in China

-

Mini Cooker Autoclave Mini Cooker

-

Edible fungus sterilization sterilizing pot sterilizing pot / shiitake mushroom sterilizing pot high-pressure sterilizer

-

food cooking

-

Hot-selling food mushroom sterilization equipment

-

35L 50L 75L 100L 120L 150L Vertical Pressure Steam Sterilizer Autoclave on Hand Wheels

-

Cooking Autoclave Food Sterilization Equipment Small Back Pressure Sterilizer

-

Sterilizer

-

cooking machine

Other Products

-

$400.00 / set

$400.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set