High pressure food sterilizer 35 50 75 100 120 150 liters back pressure water cooling sterilizing pot

-

Supplier: Guangzhou Jiangbin Trade Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Sophia Chen -

Price: $400.00 /set -

Min. Order: 1 set

| strength: | 4.5kW | Video outbound inspection: | if |

| brand: | Gibby Med | Supply capacity: | 1,000 sets per month |

| Warranty: | 1 year | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| After-sales service provided: | Free spare parts | Certification: | International Organization for Standardization |

| Voltage: | 220V | weight: | 110kg |

| Mechanical test report: | if | model: | LS-100LD |

| Name: | Water immersion continuous sterilizer | Core component warranty: | 1 year |

| Processing: | Sterilizer | port: | Guangzhou, Shenzhen, Shanghai |

| Marketing type: | normal product | Core components: | pressure vessel |

| Place of origin: | Jiangsu, China | Processing type: | food |

| Showroom location: | not any | Applicable industries: | Farm, food store, food and beverage store, other |

| Dimensions (length*width*height): | 680*630*1370mm | Packaging details: | packed in wooden box |

| Health status: | new |

Cooking autoclave for bagged or canned food 35 50 75 100 120 150 liters

2 Basic parameters

|

Model

|

Chamber size(big)

|

Fixed work stress (MPa)

|

Rated operating temperature(℃) |

Rated input consumption(kilowatt) |

timer(minute) |

Pressure(mpa)/ Temperature (℃) range (MPa/℃)

|

aspect (centimeter) |

GW/NW(Kilogram) |

|

LS-35LD |

35 |

0.22 |

134 |

1×2.5 |

0~99 |

0.07~0.22/ 105~134 |

48×46×85 |

56/42 |

|

LS-50LD |

50 |

2×1.5 |

52×52×98 |

65/55 |

||||

|

LS-75LD |

75 |

3×1.5 |

56×56×98 |

90/70 |

||||

|

LS-100LD |

100 |

59×59×108 |

105/85 |

|||||

|

LS-120LD |

120 |

3×2 |

60×64×114 |

125/100 |

||||

|

LS-150LD |

150 |

67×69×114 |

135/110 |

3 feature

a) Equipped with a pressure/temperature controller, the pressure setting range is 0.07~0.22MPa (corresponding to the saturated steam temperature 115~134℃).

b) Equipped with a safety valve that automatically releases the pressure when the sterilization pressure exceeds the allowable value.

c) Equipped with an immersed heating tube, which has the function of preventing dry burning. When the water level is low, the unit will cut off the power supply, stop heating and alarm.

4 construction

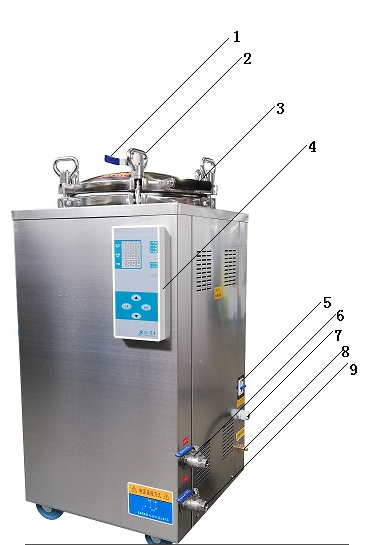

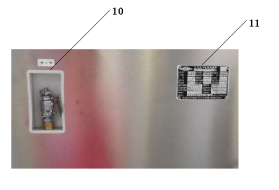

1. Inlet faucet 2. Tighten the bolts 3. Handle 4. Control panel 5. Circuit breaker switch 6. Air inlet 7. Power cord

8. Exhaust port 9. Water outlet 10. Safety valve 11. Nameplate

(Figure 1 Construction)

5 Working principle

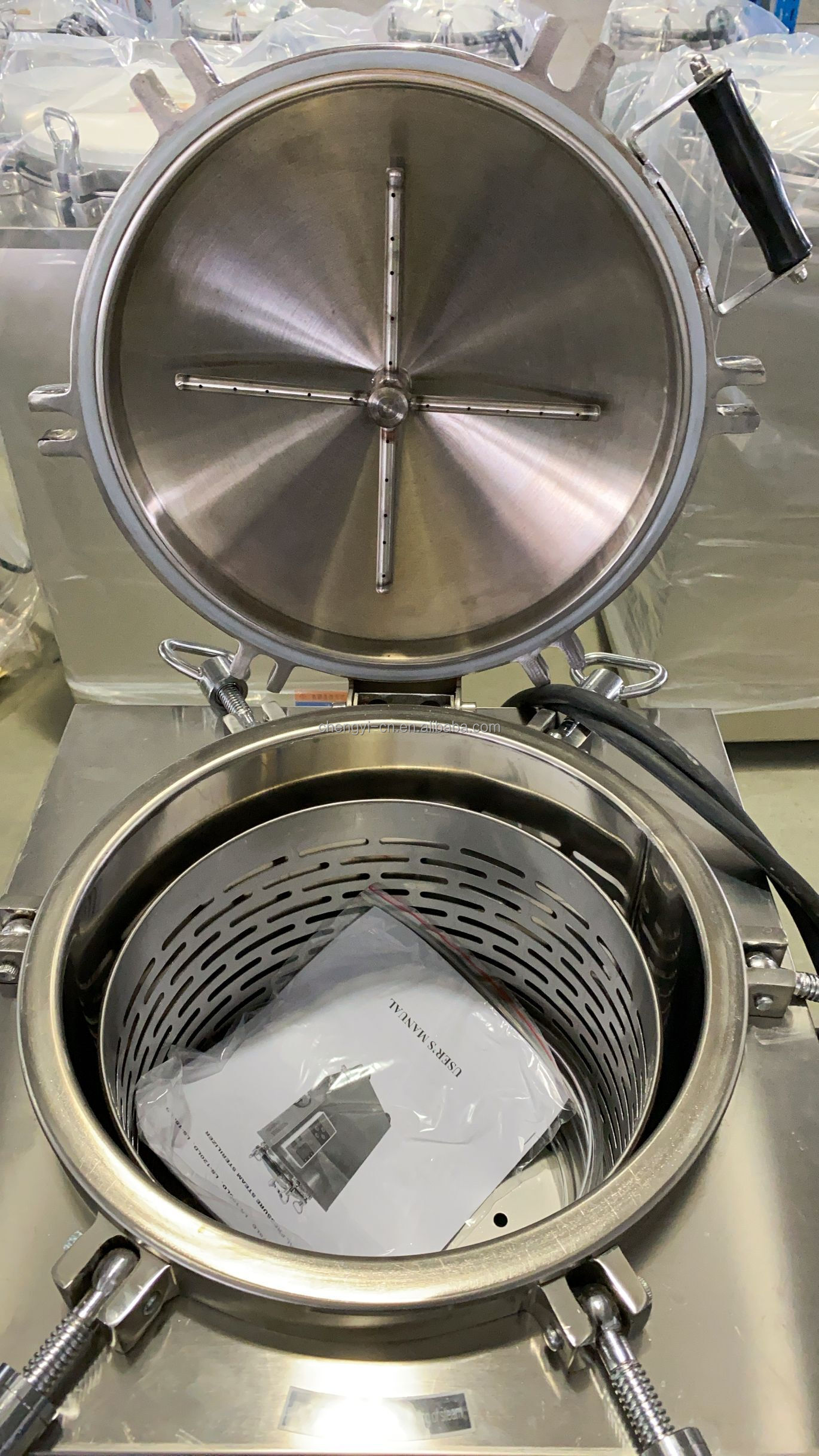

This product is designed for both disinfection and sterilization:. Direct heating produces pressurized steam. Then the pressure steam acts on the microorganisms to destroy their structure and achieve sterilization. For the rapid cooling and sterilization process, 6 liters of tap water are first injected into the chamber and then heated for about 25 minutes for sterilization while maintaining the temperature inside the chamber. Sterilization time is 35-40 minutes. After completion, manually inject 0.24MPa compressed air into the cavity, then open the drain valve 1/2 for drainage, and perform back-pressure cooling of the flexible packaging. After rapid cooling for 3 minutes and manually closing the entry of compressed air and tap water, the temperature of the objects in the box can be reduced to 30~40℃.

-

UHT Instant Milk Sterilizer

-

UHT Beverage Juice Milk Sterilizer Flat Sterilizer

-

Affordable Htst Continuous Pasteurizer

-

BIOBASE Dentist Glass Bead Mini Autoclave Small Sterilizer

-

UHT milk sterilizer

-

Small 500-1000L per hour uht milk processing plant uht milk sterilizer

-

Fully automatic 1000L/H plate milk pasteurizer

-

Hot selling UHT sterilizer for juice processing line

-

Chinese brand multi-purpose sterilizer sterilization equipment

-

commercial juice uht milk pasteurizer/small uht milk processing plant/liquid uht pasteurizer

Other Products

-

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set