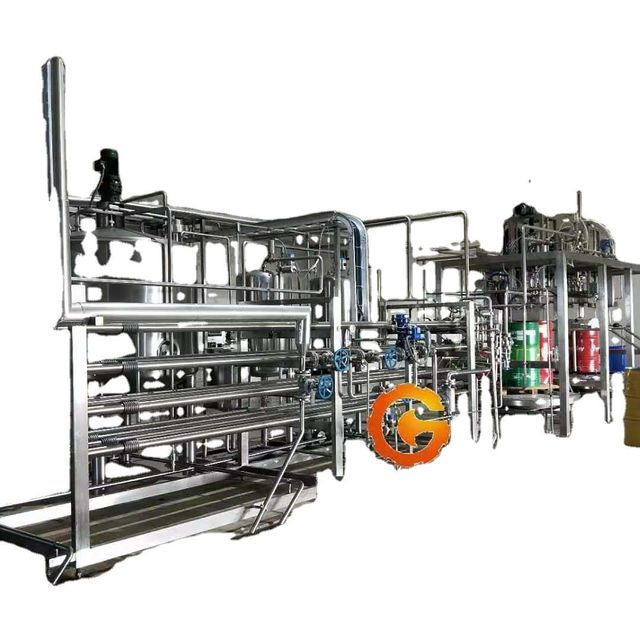

Small ultra-high temperature sterilized milk processing plant milk tray type ultra-high temperature sterilizer

-

Supplier: Shanghai Goldcheer Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Cassiya Lu -

Price: $3999.00 / 1 - 4 sets

$3666.00 / >=5 sets -

Min. Order: 1 set

| Marketing Type: | New Products 2021 | Origin: | China Shanghai |

| Warranty: | 1 year | Warranty: | 1 year |

| Supply capacity: | 2 sets of milk tray UHT sterilizers for small UHT milk processing plants per month | Packaging Details: | Standard wooden box or small ultra-high temperature sterilized milk processing plant milk tray type UHT sterilizer according to customer requirements |

| Core component warranty: | 1 year | Material: | Stainless steel SUS304 |

| weight: | 500 kg | Local service location: | Canada, Vietnam, Philippines, Pakistan, Russia, Thailand, Malaysia, Australia, Kenya, Algeria, Sri Lanka, Bangladesh, Nigeria, Uzbekistan |

| Quality of work: | durable | Certification: | International Organization for Standardization |

| Control System: | semi-automatic | Showroom location: | Canada, Vietnam, Philippines, Indonesia, Pakistan, Thailand, Morocco, Kenya, Algeria, Sri Lanka, Romania, Bangladesh, Nigeria, Uzbekistan, Malaysia, Australia |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Package preview: | |

| Health status: | new | Core components: | PLC, motor |

| Voltage: | 380V | port: | Shanghai |

| Sterilization method: | Steam 121C Sterilization | Mechanical test report: | if |

| Main selling points: | Famous PLC | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, UHT |

| Function: | Milk and Juice Sterilizers | strength: | 3-13KW |

| application: | Milk and Juice Sterilizers | brand: | Jin Xier |

| Video shipment inspection: | if | Name: | UHT milk sterilizer for small UHT milk processing plant |

| After-sales service provided: | Engineers available to service machinery overseas | Applicable industries: | Manufacturing Plant, Food and Beverage Factory, Food and Beverage Store |

| Dimensions (L*W*H): | 3500mm*1800mm*2300mm | heating method: | steam heating |

Description of Plate UHT Sterilizer

This equipment is used for pasteurization of heat-sensitive products such as milk, fruit juice, tea beverage, soy milk, milk beverage, etc. It can also be used for pre-sterilization of milk when producing pasteurized milk (long-term milk).

Technical Description

The plate type ultra-high temperature sterilizer can be applied to the production of milk and fruit juice beverages. It can be connected with aseptic filling machine. The product shelf life can reach 3~6 months. It can be connected with centrifuge, degasser and flash evaporator. When using the full flow homogenization method, the capacity can be controlled by the flow controller and homogenizer. The heat recovery efficiency reaches 90%, because the heating and cooling of materials are completed in the heat recovery stage.

- Fully automatic type: This equipment is controlled by Omron PLC, which controls the entire production stage according to requirements; the CIP system equipped with this equipment can be cleaned automatically.

- Semi-automatic type: semi-automatic control of running operation. The operator can control the pump and return function through the control panel; the sterilization temperature is maintained by the automatic temperature controller and continuously resequenced by the plotter.

Process: 30~75℃→140℃(4S, 10S, 15S)→85~92℃→(40℃) return

Cooling water 1:2 ≤30°C (standby)

|

Capacity (tons/hour) |

Steam consumption (kg/h) |

Vapor pressure (bar) |

Power (kW) |

Dimensions (length x width x height) |

Weight (kg) |

|

1 |

120 |

6.0 |

2.8 |

1.6×1.4×2.0 |

950 |

|

2 |

240 |

6.0 |

3.0 |

1.6×1.4×2.0 |

980 |

|

3 |

360 |

6.0 |

3.7 |

1.8×1.6×2.0 |

2420 |

|

4 |

480 |

6.0 |

3.7 |

1.8×1.6×2.0 |

2570 |

|

5 |

600 |

6.0 |

3.7 |

1.8×1.7×2.0 |

2940 |

|

6 |

720 |

6.0 |

3.7 |

1.8×1.7×2.0 |

3300 |

|

8 |

960 |

6.0 |

4.4 |

2.5×2.0×2.0 |

3700 |

|

10 |

1200 |

6.0 |

7.0 |

3.0×2.0×2.2 |

4200 |

|

15 |

1800 |

6.0 |

8.0 |

4.5×2.0×2.0 |

4500 |

|

20 |

2400 |

6.0 |

11.0 |

4.5×2.0×2.2 |

5600 |

Usually packed in wooden cases, we can also do other packing according to customer's requirements.

As a professional food machinery manufacturer and supplier in China, GC Machinery provides services including installation, commissioning and operator training. We can provide a complete production line flow chart. We provide customers with detailed and comprehensive layout schemes so that they can better understand the equipment they are purchasing. Our lead time is between 30-90 days, largely depending on factors such as order quantity and equipment specifications. All of our machines come with a one-year warranty. During this period, we provide free equipment parts. Lifetime equipment maintenance service is also provided. In addition, we also provide equipment installation and customization services. Operator training services are available upon request.

We have professional knowledge and experience on products and markets, so we can provide you with turnkey solutions for the food machinery industry. No matter what the market is, we can design for you.

-

Food processing water spray sterilizer pot sterilizer machine made in China

-

Mini Cooker Autoclave Mini Cooker

-

Edible fungus sterilization sterilizing pot sterilizing pot / shiitake mushroom sterilizing pot high-pressure sterilizer

-

food cooking

-

Hot-selling food mushroom sterilization equipment

-

35L 50L 75L 100L 120L 150L Vertical Pressure Steam Sterilizer Autoclave on Hand Wheels

-

Cooking Autoclave Food Sterilization Equipment Small Back Pressure Sterilizer

-

Sterilizer

-

cooking machine

-

Counter Pressure Retort Autoclave For Bottle/Canned/Pouches Food

Other Products

-

$5000.00 / set

$5000.00 / set