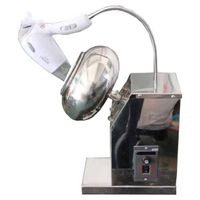

lab small chocolate coating machine

-

Supplier: ZHEJIANG LEADTOP PHARMACEUTICAL MACHINERY CO.,LTD -

Region: Zhejiang, China -

Contact: Mr Baggio Chan -

Price: $1750.00 /set -

Min. Order: 1 set

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Food & Beverage Shops,Pharmaceutical Industry; | Warranty: | 1 year; |

| Certification: | CE/ISO; | Key Selling Points: | Easy to Operate; |

| Port: | Ningbo or Shanghai; | Usage: | Pharmaceutical; |

| Weight: | 300; | Coating Type: | Heating & Coating; |

| Condition: | New; | After Warranty Service: | Online support; |

| Production capacity (Kg/time): | 50~70; | Brand Name: | LTPM CHINA; |

| Voltage: | 220V(it depends on your country); | Boiler rotating speed: | 32; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Electric oven wire power (Kw): | 4KW; |

| Coating Drum Diameter (mm): | 1000 mm; | Model: | SHL-1000; |

| Machine weight (kg): | 300; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Packaging Detail: | Exported Standard Wooden Case; | After-sales Service Provided: | Online support; |

| Coating Temperature (℃): | 50 - 70 ℃; | Place of Origin: | Zhejiang China; |

| Main motor: | 1.5kw; | Supply Ability: | 25 Set/Sets per Month Pharmaceutical Film Coating Machine; |

| Showroom Location: | United States,Pakistan,Colombia; | Max. Load Capacity (kg): | 50 kg; |

| Boiler diameter mm: | 1000; | Hot air outlet temperature(℃): | 50~60; |

| Local Service Location: | United States,Brazil,Peru,Pakistan,Mexico,Argentina,Chile,Colombia; |

lab small chocolate coating machine

Lab small chocolate coating machine

Application:

Water nut type sugar coating machine is mainly used to press shaped slice, pill and the coating of granules in pharmaceutical industry, and also used for candy manufacturing or coating in foodstuff industry.

Sugarcoated tablets after polishing coating have polished surface, which can prevent oxidation, damping or volatilization, in addition, it can envelop bad smell and enable the drug to be conveniently identified and slow dissolution in the intestines and stomach.

Main Techinical Parameters:

Parameter Model | SHL-200 | SHL-300 | SHL-400 |

Boiler diameter mm | 200 | 300 | 400 |

Production capacity (Kg/time) | 1 | 1-2 | 2-5 |

Clockwise angle α (adjustable) | 15°~45° | 15°~45° | 15°~45° |

Boiler rotating speed | 0-40r/min | 0-46r/min | |

Main motor | 0.37KW | 0.37KW | 0.37KW |

Fan motor | 60W | ||

Electric oven wire power (Kw) | 0.8 | 1.5 | |

Hot air outlet temperature(℃) | 50~60 | ||

Machine weight (kg) | 100 | 120 | 120 |

Working Principle:

This machine has the advantages of simple and easy operation, smooth, bright, delicate, one-sided saving accessories, maintenance is simple, it is the first choice of ideal equipment for experiment.

This machine suits for sugar and film coating for Chinese medicine and Western medicine. It consists by the host (sugar coating machine), controllable hot air system, automatic liquid gas spray system etc. The variable frequency speed of the main motor is adjustable. The coating material will be coated in the surface of the tablet with high atomizing spray accessories automatically, the tablets in the coating pan for will be continuous complex movement, so that the coating liquid evenly wrapped in each tablet. There is hot air which can be controllable will dry the tablet.

Materials flow curve diagram:

The main motor is driven by the triangular belt, with the worm and the wormwheel slow down, the boiler obtains a reasonable rotation speed. The boiler operates smoothly and can self lock.

Main Parts and Components:

Description | Type | Quantity | Standard | Intended place |

Single line conical roller bearing | 7310 | 2 | GB297-84 | Both sides of worm |

Single line conical roller bearing | 7206 | 2 | GB297-84 | Both sides of worm |

triangular belt, | B-1118 | 1 | GB-1171-74 | Motor-worm |

Frame rubber oil seal | FB25×45×10 | 1 | GB98771-88 | Right shaft cover of worm |

O rubber seal ring | 60×3.1 | 2 | GB-1235-76 | Cover of both shafts of worm |

If you are interested in our machines, please feel free to contact us!

-

BYC-600 sugar coating machine is used for sugar coating of tablets and pills in the food industry

-

Nut/Chocolate/Almond Peanut Candy Coating Pan Machine Nut Icing Machine

-

Hot Sale Stainless Steel Small Pill Candy Sugar Diaphragm Coating Machine

-

BYC 800 sugar coating machine, tablet and pill coating machine, sugar coating machine

-

Commercial Fondant Sugar Coating Machine Almond Nut Peanut Solution Coating Machine

-

Hot Sale All Stainless Steel Tablet Film Coating Equipment Sugar Coating Machine

-

Laboratory Tablet Coating Machine Pharmaceutical Equipment

-

Food Small Automatic Nut Candy Candy Chocolate Peanut Almond Candy Tablets Nano Film Coating Pot Machine Coating Machine

-

Polishing machine Peanut tablet coating machine

-

Small candy nut icing pan machine

Other Products

-

$30000.00 - $60000.00 / set

$30000.00 - $60000.00 / set -

$30000.00 - $60000.00 / set

$30000.00 - $60000.00 / set -

$25800.00 / set

$25800.00 / set -

$25800.00 / set

$25800.00 / set -

$25800.00 / set

$25800.00 / set