Gypsum powder/ board /cornice manufacturing equipment with factory price

-

Supplier: Feixian Dongyue Gypsum Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Cathy Dong -

Price: $200000.00 /set -

Min. Order: 1 set

| After Warranty Service: | Online support,Field maintenance and repair service; | Single package size: | 10X10X10 cm; |

| Name: | Gypsum powder production line; | Package Type: | standard exporting containers, such as 40' OT, and 40' GP; |

| Brand Name: | Dongyue; | Dimension(L*W*H): | 900*900*1800; |

| After-sales Service Provided: | Video technical support; | Single gross weight: | 10 KG; |

| Place of Origin: | Shandong China; | Condition: | New; |

| Applicable Industries: | Manufacturing Plant,Construction works ; | Warranty: | 1 year; |

| Raw material: | Natural Gypsum; | Voltage: | 380V; |

| Showroom Location: | None; | Application: | desulfurized gypsum powder, phosphorus gypsum powder,etc; |

| Key Selling Points: | Easy to Operate; | Power(W): | 330KW; |

| Useage: | which is mostly used in gypsum industries; | Local Service Location: | None; |

| Selling Units: | Single item; | Application: | Gypsum Board; |

| Automatic Grade: | Automatic; | Features: | Energy-saving; |

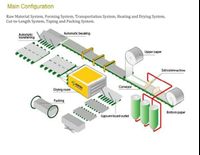

High capacity full automatic gypsum powder production line equipment

Introduction

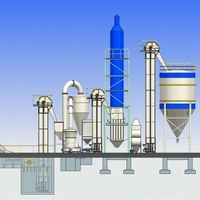

Steam (thermal oil) blade dryer and boiling furnace production process

Product scope of application: desulfurized gypsum powder, phosphorus gypsum powder, citric acid gypsum powder, lactic acid gypsum powder

1. According to the unstable characteristics of the domestic chemical gypsum free water content, the device uses a more energy-saving two-step calcination process of one dehydration and two calcination, which is to use a heat source to do two respectively, that is, the use of the residual heat emitted by the calcination system for the equipment's pre-drying system for secondary work, the final emission temperature can be lower than 100 degrees C, so very energy-saving. Because the use of a heat source, so greatly shorten the installation cycle, while saving a large number of raw materials, is very reasonable, very energy-saving chemical gypsum calcination system. Also because the design output of the equipment is high, it uses the current most stable heating power plant steam or natural gas and other processes to provide heat sources, the main features of the process is to save electricity, easy operation, maintenance and long service life; Calcination system We use a chamber boiling calcination furnace, through the continuous update and improvement of the furnace body, can achieve the heat distribution tend to be reasonable, heat exchange area can be infinitely increased, can adapt to the annual output of chemical gypsum 30,000 tons to 200,000 tons of production requirements of different customers. Dust removal system adopts a first-level cyclone separation plus two-stage dust removal, the first-level cyclone dust can be pre-drying material s95% directly collected, the first-level dust removal gas after the direct emptying through the second-level dust removal, the concentration of gas dust is not higher than the national provisions of 10mg/m3.

2. Advantages of pre-drying process using steam blade dryer

After pre-drying, the gypsum powder raw material with uniform moisture content is obtained

Steam low temperature pre-drying makes gypsum powder better and slowly dehydrated and increases product strength.

No air flow dryer produces high wind volume and dust phenomenon.

Treatment processes such as steam-free coal-free desulfurization

Finished product quality

Product quality: finess 80, initial setting 6-10mins, final setting 10-15mins.

The finished gypsum powder contains CaSO4-1/2H2O, which is β gypsum powder, which is mostly used in gypsum industries: gypsum ceiling, gypsum cornice, paper gypsum cornice, gypsum putty powder, etc.

1.Do you have sample project?

Answer: Of course. Welcome to Dongyue sample projects in anytime.

2.Do you have after sales support?

Answer:Yes, we are happy to give advice and we also have skilled technicians available across the world. We can help your machines running in order to keep your business running.

3. What can you do if the machine broken?

Answer:Our machine's warranty period is 12months, if the broken parts can't repair, we will send the new parts replace the broken parts free, if after warranty period, we will supply the technical support for the whole life of the equipment.

4.How long the machine could be made?

Answer: Normally need about 30-80 working days, also depends on the model of machines.

5. Are you a new factory?

Answer:No, Dongyue more than 26 years history and do exporting since 1993.

6.Have more question or requirement?

Answer:Please contact us as below information.

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

Other Products

-

$25000.00 / set

$25000.00 / set -

$250000.00 / set

$250000.00 / set -

$25000.00 / set

$25000.00 / set