Rubber cutter machine/rubber cutting machine/wasted tire recycling machine for rubber powder

-

Supplier: Henan Machinery& Equipment Company Limited -

Region: Henan, China -

Contact: Mr wayne law -

Price: $1000.00 /unit -

Min. Order: 1 unit

| Tire Machine Type: | Tire Recycling Machine; | After-sales Service Provided: | Free spare parts,Field maintenance and repair service,Video technical support,Field installation, commissioning and training,Online support; |

| Place of Origin: | Henan China; | Name: | Waste Tire rubber powder recycling Plant; |

| Port: | qingdao; | rubber powder mesh: | 20-120mesh; |

| Color: | Customizable; | Voltage: | 380V/50HZ/3P; |

| Model Number: | XKP-450; | Packaging Detail: | standard export packaging for wasted tire recycling machine; |

| Supply Ability: | 20 Set/Sets per Month; | Application: | Rubbers Recycling Industry; |

| Payment Terms: | L/C,D/P,T/T,MoneyGram; | Function: | Recycle Waste Rubber; |

| Capacity: | 200-1200kg/h; | End product: | Scrap Tire, rubber powder, rubber particle; |

| Power(W): | 1.5KW - 75 KW; | Raw material: | 600-1200mm Waste Tire; |

| Warranty: | 2 Years; | Weight: | 200-13000kg; |

| Advantage: | Environmental Protection, safty, egnergy saving; | Dimension(L*W*H): | 2080*1000*2130 mm; |

| Certification: | CE ISO SGS; | Brand Name: | MS; |

| Condition: | New; |

rubber cutting machinery/tire recycling machine

for rubber powder

Features of waste tire recycling machine for rubber powder:

Tire recycling machine for rubber powder

is used to crush the waste tire into rubber powder.

Tire recycling machine for rubber powder can get the rubber powder with purity of 99.9%.

Have got national patent certification and all machines have 2 years warranty.

Advantages of tire recycling machine for rubber powder:

1. Our machines have got national patent certification;

2. There are two grooved rollers on our tire crusher,

3. The material used on the rollers is high manganese anti-abrasioinalloy, no need to change forever, old type adopt cast

iron, which is easy to break up. And we offer 3 years warranty to

rollers.

4. Our machines use antifriction bearing system (rolling friction), the old type adopt bush (slide friction), and the bush is very easy to burnt.

Flow process of tire recycling machine for rubber powder:

Waste tire---Tire circle cutting---Tire bead wire separating---Tire strip cutting---Tire block cutting---Rubber crushing--- magnetic separating ---vabrating screen--Rubber powder

Detailed Products

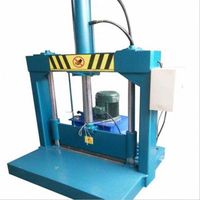

1. Tire Circle Cutter Machine

Tire circle cutter is used to cut and open the joint of tire's side and top.

Name

| Motor power | Weight | Capacity | Tire specification |

Tire Circle Cutter | 3kw | 500kg | 20-40 pcs/hr | 600-1200mm (Both reinforced and nylon tires) |

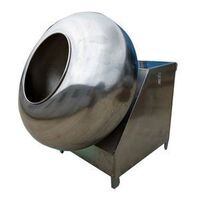

2. Tire Bead Wire Separator

Tire bead wire separator is used to separate the steel rims around the tire to avoid the harm to the machine.

Name | Motor power | Weight | Capacity |

Tire bead wire separator | 7.5kw | 1300kg | 100pcs/h |

3. Tire Strip Cutter Machine

Tire strip cutter is used to cut the tire cirlce into strips 5x8 cm .

Name | Motor power | Weight | Capacity | Cutting size |

Tire strip cutter | 4kw | 850kg | 1000kg/h | 5x8cm |

4. Tire Block Cutter Machine

Tire block cutter is used to cut the strips into small chunks about 3.5 cubic centimeter.

Name | Motor power | Weight | Capacity | Cutting size |

Tire block cutter | 4kw | 800kg | 0.8t/h | 3x5x8cm |

5. Rubber Crusher

Rubber crusher is used to grind the rubber chunks into smaller mesh powder through the vibrating screen as you need.

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

Service on Sale

1.Providing initiative and enthusiastic service;

2.Introducing & Demonstrating products and its application to clients;

3.Helping clients to choose equipments.

After-sales Service

1.Highly inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3. Assisting our clients for foundation construction of equipments;

4.Dispatching engineers to install and debug equipments;

1. Purity of the final rubber powder:

We can get the rubber powder in 99.9% purity, cause we separate the wire steels

twice by the magnetic separator.

2. About the installation and training:

Our engineer are available to help our customers with the installation and training

with the machines overseas; If you want, we will of course welcome you to come here for learning how to operate the machines.

3. QC

Third party inspection: acceptable

2 years guarantee for quality problems

4.Payment :

TT, 30% deposit ,70% before shippment.

5.Available shipment Port:

FOB Qingdao

Why choose us?

1). Technology

We adopt advanced technology, high efficiency, lower labor and power consumption, more than 15 years using life.

2). Warranty

For all machines, we offer 2 years warranty. For the rollers on the tire crusher, we offer 3 years warranty. Anything wrong with the spare parts, we can send you a new one for free.

3). Quality

Our machines made by the quality alloy, especially for the rollers on tire crusher, it adopts one kind of abrasion-resistant alloy, alloy high manganese anti-abrasioin alloy, which makes the machines are durable.

4). Factory visit

We definitely welcome you to come here for factory visiting, we can make sure that all our machines operation process can be showed for you.

-

rubber cutting machine / rubber powder making machine / rubber powder production line

-

Automatic tire slicing and cutting machine tire recycling machine YG1200 tire cutting machine factory sale

-

Industrial Rubber Processing Machinery Gravel Cutting Machine/Hydraulic Rubber Pack Cutting Machine

-

Automatic rubber strip cutting machine slitting machine rubber cutting slitting machine

-

Efficient OEM Ultrasonic Sewing Machine Woven Bag Sewing Machine Non Woven Bag Sewing

-

Waste Rubber Cutting Machine/ Used Tire Cutting Machine/ Used Tire Recycling

-

Automatic rubber sheet slitting machine, rubber slitting machine, rubber slitting machine

-

Single Knife Hydraulic Baler/Rubber Cutting Machine

-

Silicone Rubber Cutting Machine, Silicone Rubber Cutting Machine, Rubber Slitting Machine

-

Rubber Press Plastic Rubber Machinery Rubber Slitting Machine

Other Products

-

$600.00 / set

$600.00 / set -

$2000.00 / set

$2000.00 / set -

$1000.00 / set

$1000.00 / set -

$5250.00 / set

$5250.00 / set -

$13000.00 / set

$13000.00 / set -

$3823.00 / set

$3823.00 / set