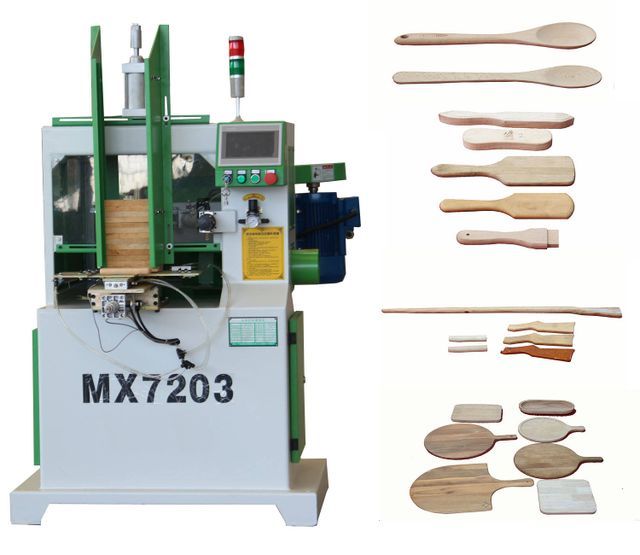

Wood profiling machine sanding function CNC wood profiling machine MX7203

-

Supplier: Zhengzhou Chryso Machinery Import&Export Co., Ltd. -

Region: Henan, China -

Contact: Ms Annie Wong -

Price: $4500.00 / 1 - 2 sets

$4350.00 / 3 - 4 sets

$4150.00 / >=5 sets -

Min. Order: 1 set

| Warranty: | 1 year | Packaging details: | The automatic spindle forming machine and wood imitation forming machine will be packed in standard export wooden boxes or according to customer requirements. Delivery time: 10-15 days Woodworking automatic profiling molding machine for bent legs |

| Core component warranty: | 1 year | Motor Power: | 4kW |

| Working height: | 5-130mm | Core components: | engine |

| application: | Woodworking imitation forming machine | Supply capacity: | 20 sets of woodworking automatic profiling machines for bent legs per month |

| Spindle diameter: | 25.4mm | Video outbound inspection: | if |

| Showroom location: | not any | Maximum working thickness (mm): | 130mm |

| product name: | Automatic wood imitation molding machine | Applicable industries: | carpentry wood replica |

| Mechanical test report: | if | Health status: | new |

| brand: | Chronic RS | net weight: | 1200kg |

| Package preview: | Number of axes: | 4/8 | |

| Feeding speed: | 4-20 rpm | Spindle speed: | 12000 rpm |

| aspect: | 1200*1500*1200mm | Spindle diameter (mm): | 25.4mm |

| port: | Port of Guangzhou, China | Working length: | 50-300mm |

| Weight (kg): | 1200kg | Voltage: | 380V |

| Dimensions (length*width*height): | 1200*1500*1200mm | payment terms: | Western Union, wire transfer, MoneyGram |

| Marketing type: | Hot Products of 2019 | Working width: | 15-100mm |

| Main selling points: | automatic | Place of origin: | China |

Woodworking automatic profiling machine

Fully automatic wood profiling machine, electro-hydraulic control, hopper feeding, is a newly developed version successfully designed by our company, used for processing small wood products of different shapes, such as column caps, brushes, knife handles, toy accessories, handicrafts, spoons, Flat pieces for wooden lids, hats, toasters, etc., and other round, oval or irregular shaped workpieces.

| final production |

This model of wood profiling machine is widely used to process various small wood products, such as wooden covers, wooden post caps, brushes, tool handles, spoons, wooden toy accessories, handicrafts, etc.

| Technical Parameters |

This model of wood replica shaper uses wooden boards that are roughly cut to size and planed to the desired thickness.

A unique advantage of this wood profiling forming machine is that the machine automatically feeds materials, and one worker can operate at least three machines, which will greatly improve your workshop production capacity, save more labor costs, and create more products for you value.

The cutting machine is the template controller, and oil pressure fixes the template driven roller to the preform mold. The pressure on the mold can be adjusted to ensure that the pressure is always constant, even when producing complex shapes.

The rotational speed of the hydraulically driven table is electronically controlled by a switch console.

Additionally, the workbench can be set to different cycle speeds depending on the complexity of the job. When producing relatively thin parts, up to two blanks can be stacked on top of each other and formed together in a continuous cycle.

| Mx7216ABCD parameters |

Setup is easy and changeover times are reduced due to improvements in the electro-hydraulic control system and many drive and operating elements. The output of this wood replica shaper depends greatly on the shape and form. Work piece size, 3-6 pieces per minute.

This wood replica molding machine is fully equipped.

-

Automatic Feeder Slide Table Spindle Forming Woodworking Machine With Feeder

-

Carpentry Lumber Sliding Table Wood Furniture Vertical Single-Axis Planer Forming Milling Machine Milling Machine

-

Shoot Brand Wood Shaper, WS-1/2A/WS-1/2

-

MX5615A Slide Table Milling Machine Spindle Milling Machine Woodworking Tilting Spindle Milling Machine

-

China factory wood thread vertical shaft forming machine

-

MX5112 Vertical Single Axis Woodworking Milling Machine / Milling Machine Wooden Spindle Forming Machine Spindle Forming Machine

-

High Precision Industrial Sliding Table Spindle Forming Machine

-

Hisimen H0351 Spindle Forming Machine Made in China

-

MX5117T Woodworking Vertical Single Spindle Milling Machine

-

Single Head CNC Router machine

Other Products

-

$1590.00 - $1690.00 / set

$1590.00 - $1690.00 / set -

$44890.00 - $46780.00 / set

$44890.00 - $46780.00 / set -

$5980.00 / set

$5980.00 / set -

$2200.00 / unit

$2200.00 / unit -

$2500.00 / set

$2500.00 / set